Motor employing immersion type evaporative cooling and structure optimization method thereof

A technology of evaporative cooling and optimization method, which is applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of inapplicable parameter selection, failure to play the advantages of immersion evaporative cooling technology, etc., and achieve the reduction of external dimensions , Improve power density and reduce manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

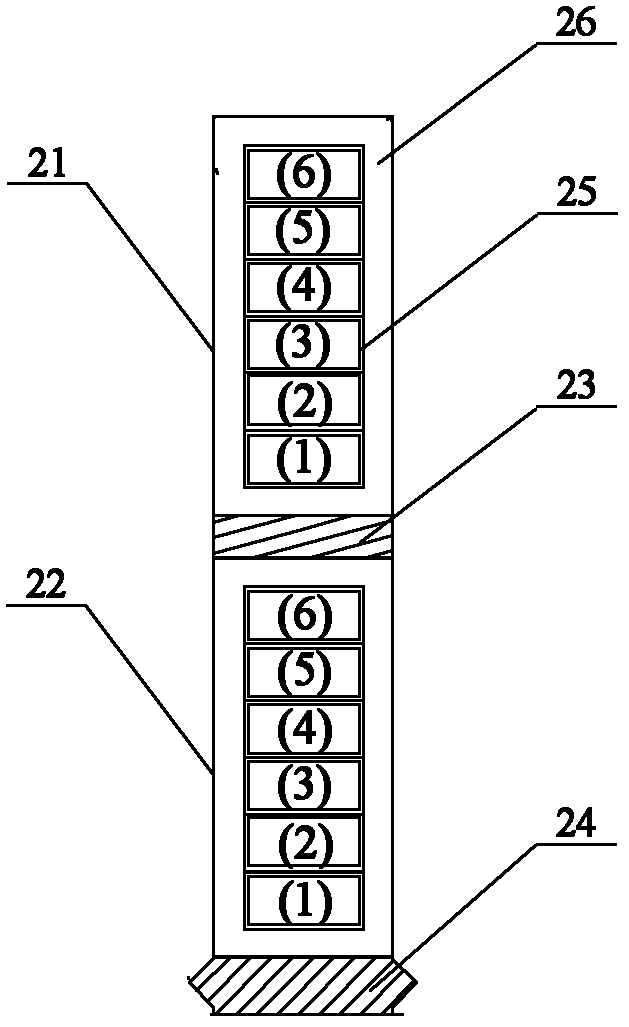

[0037] The core of the present invention is to provide a motor using immersion evaporative cooling and its structural optimization method, which fully utilizes the insulation and heat transfer performance of the evaporative cooling medium, takes advantage of the immersion evaporative cooling technology, and improves the power density of the motor , so that under the same voltage level and capacity, the optimized motor and its main components are greatly reduced in size, thereby reducing the manufacturing cost of the motor. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] Without loss of generality, this implementation mode takes an asynchronous motor as a specific example for description. It should be understood that, based on the common knowledge of those skilled in the art, the technical solution provided by the present invention is also applicable to a horizontal motor using immersion e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com