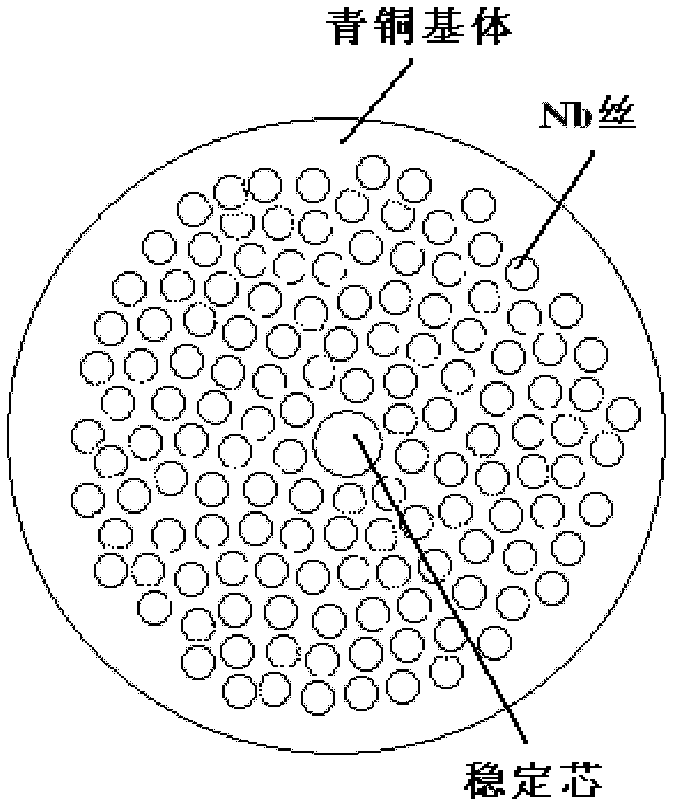

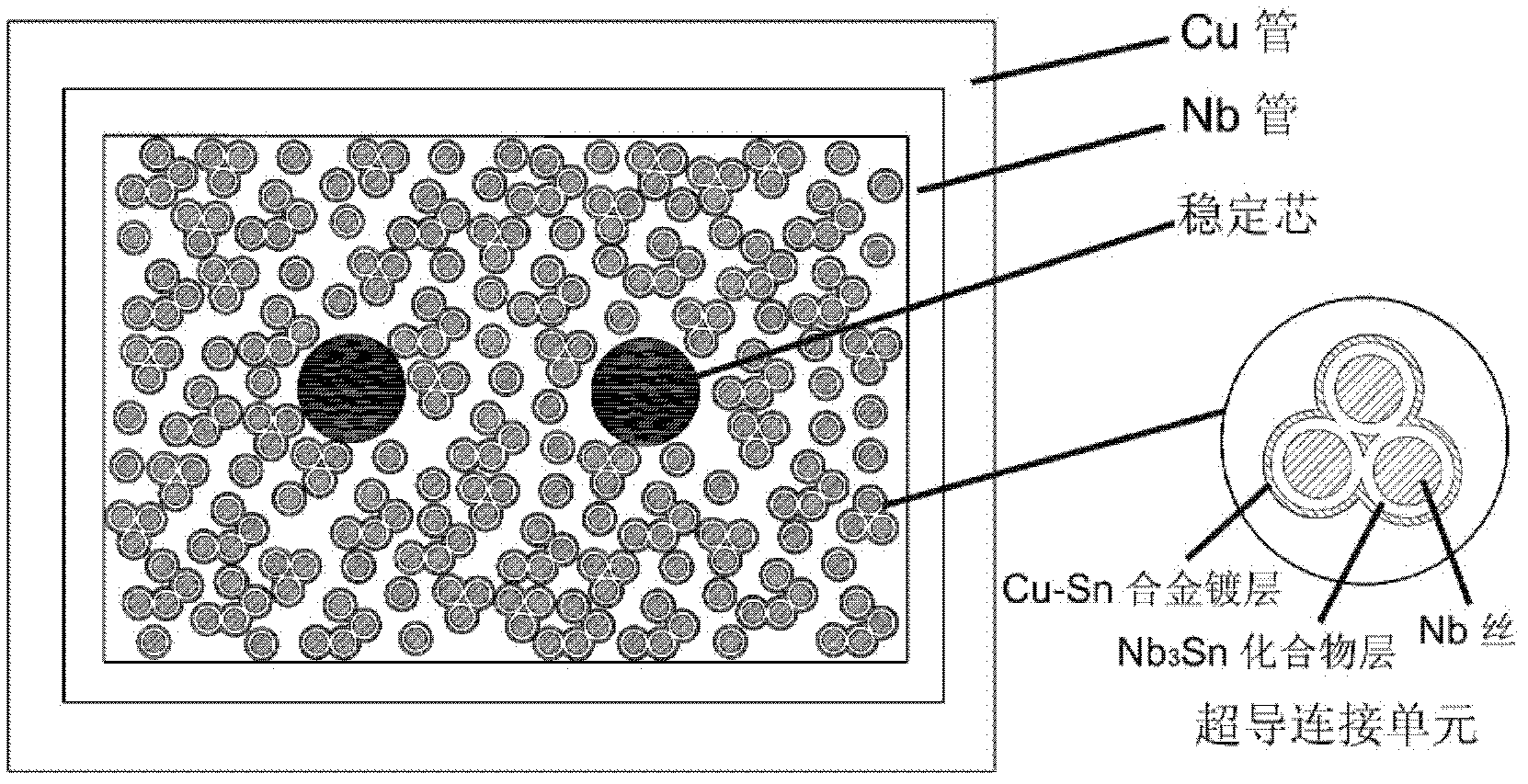

Nb3Sn superconductor multi-core cable joint adopting bronze process and preparation method of Nb3Sn superconductor multi-core cable joint

A technology of superconductors and multi-core wires, applied in the direction of connecting contact materials, connections, circuit/collector components, etc., can solve problems such as reducing joint resistance, joint non-superconducting connections, superconducting wires are easy to damage, etc., and achieve reduction Effects of joint volume, reduction of resistance value, and improvement of current-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

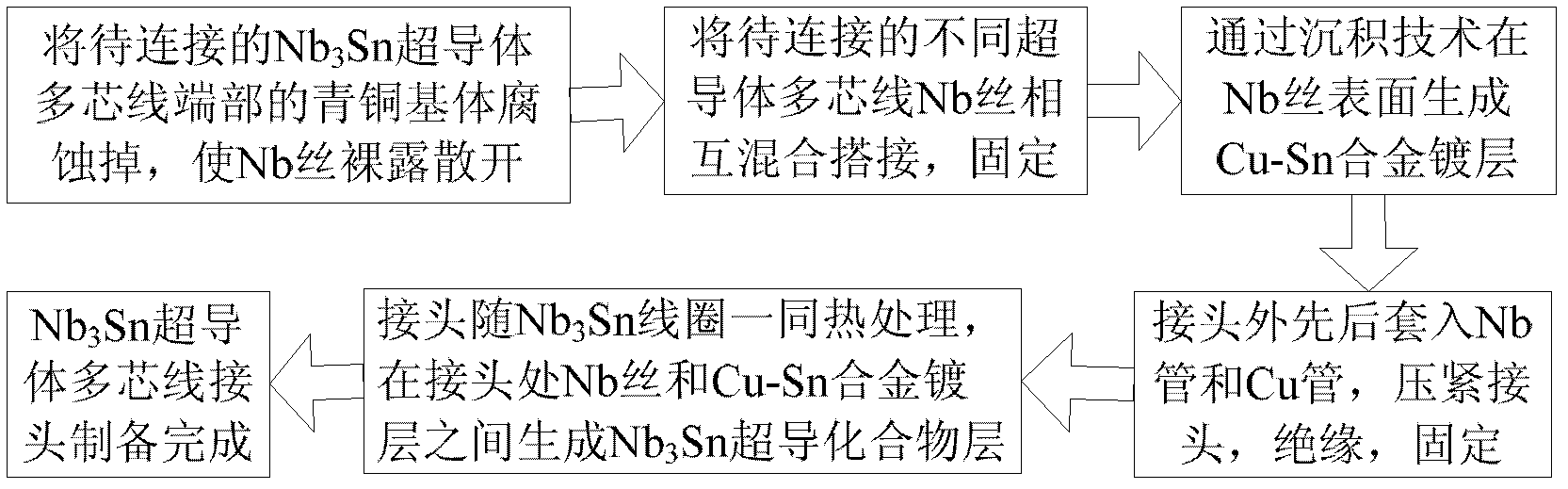

[0041] In this embodiment, the bronze process Nb to be connected 3 The outer diameter of the Sn superconductor multi-core wire is 0.9 mm, and the diameter of a single Nb wire is 4.5 microns. First use concentrated nitric acid to dissolve the two bronze process Nb to be connected 3 The bronze matrix at the end of the Sn superconductor multi-core wire was corroded, exposing the pure Nb wire part, and the length of the exposed Nb wire was 30 mm. Clean and dry the Nb wire at the joint. Then put the Nb wires of the superconductor multi-core wires together so that the Nb wires of the two wires overlap each other as much as possible, and bind and fix them with thin Cu wires. Then the joint is subjected to electroplating deposition Cu-Sn alloy layer treatment, the composition ratio of electroplating deposition electrolyte is: SnCl 2 2H 2 O——40 g / L, NaF——30 g / L, N(CH 2 COOH) 3 - 20 g / L, CuSO 4 ·5H 2 O - 30 g / L, EDTA 45 g / L, citric acid - 10 g / L, polyoxyethylene fatty ether - 2 ...

Embodiment approach 2

[0043] In this embodiment, the bronze process Nb to be connected 3 The diameter of the Sn superconductor multi-core wire is 0.7 mm, and the diameter of a single Nb wire is 4.5 microns. First use concentrated nitric acid to dissolve the two bronze process Nb to be connected 3 The bronze matrix part at the end of the Sn superconductor multi-core wire was corroded to expose the pure Nb wire part, and the exposed Nb wire had a length of 40 mm. Clean and dry the Nb wire at the joint. Then put the Nb filaments of the superconductor multi-core wire together so that the two Nb wires 3 The Nb wires of the Sn superconductor multi-core wire overlap each other as much as possible, and are bound and fixed with thin Cu wires. Then the joint is subjected to electroless plating deposition Cu-Sn alloy layer treatment, the composition ratio of electroless plating deposition electrolyte is: SnCl 2 2H 2 O——30 g / L, NaF——30 g / L, N(CH 2 COOH) 3 - 25 g / L, CuSO 4 ·5H 2 O——20 g / l, EDTA——25 g / l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com