Disposable nickel hydrogen battery negative electrode material, negative electrode piece, battery and preparation methods thereof

A nickel-metal hydride battery and negative electrode material technology, applied in the direction of alkaline battery electrodes, alkaline battery manufacturing, battery electrodes, etc., can solve problems such as pulverization, alloy cracks, etc., and achieve high efficiency, long discharge time, and convenient operation and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

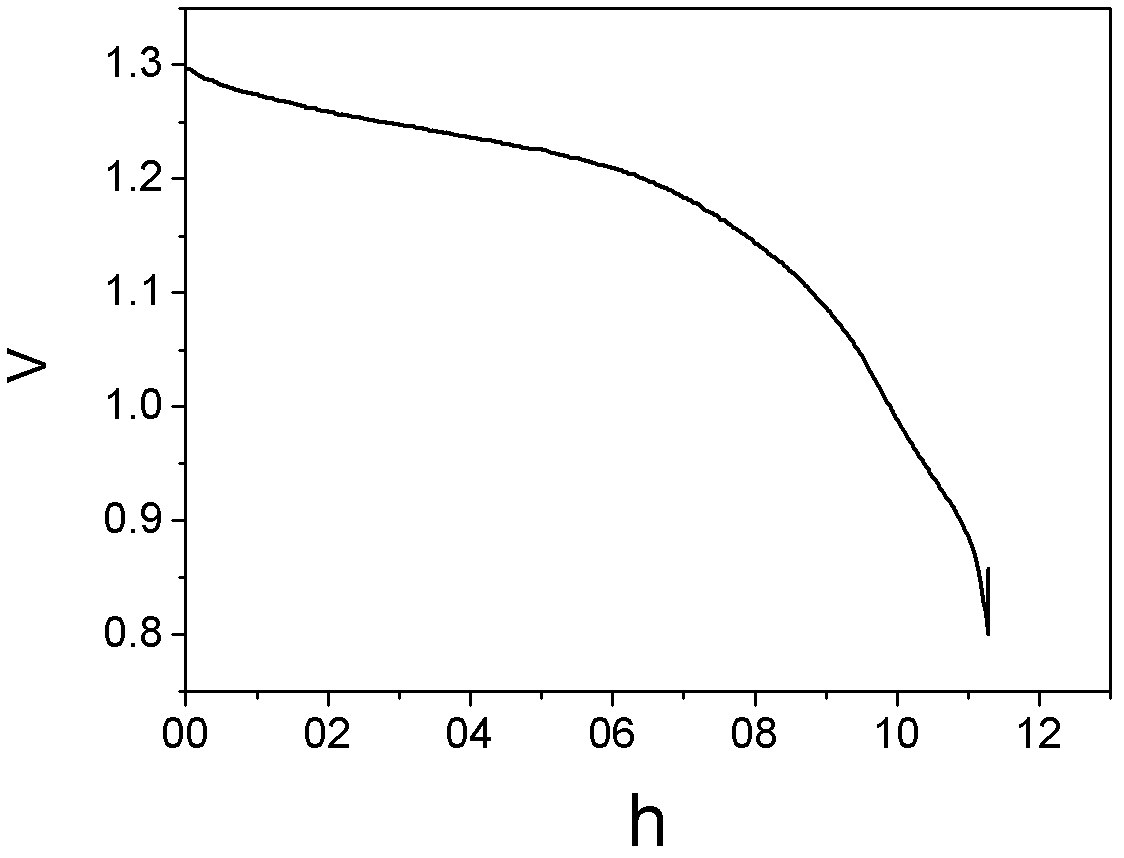

Embodiment 1

[0054] (1) Weigh 1.4142g LaNi respectively 5 , 0.0867gMgH 2 , 0.0635g nickel foam, 0.4998g nickel hydroxide powder, LaNi 5 , MgH 2 , Hydroxynickel powder is 200 mesh powder after sieving;

[0055] (2) Mix the powder evenly;

[0056] (3) Put the powder into the stuffing tank of the battery stamping system, the filling amount is half of the total amount of the above powder, then put a piece of nickel foam with a diameter of 10mm, and then put the remaining half of the powder into the tablet for tableting , to obtain a disc with a diameter of 10mm, the test force selected during the tablet pressing process is 15KN, and the pressure is maintained for 2min;

[0057] (4) take out above-mentioned wafer after sheet pressing is finished, then weld on a section of long be 10cm, wide be the nickel bar of 5mm with AC spot welding machine, make required negative plate;

[0058] (5) Wrap the disc welded with nickel strips with diaphragm paper with a length of 7.7cm and a width of 5cm, ...

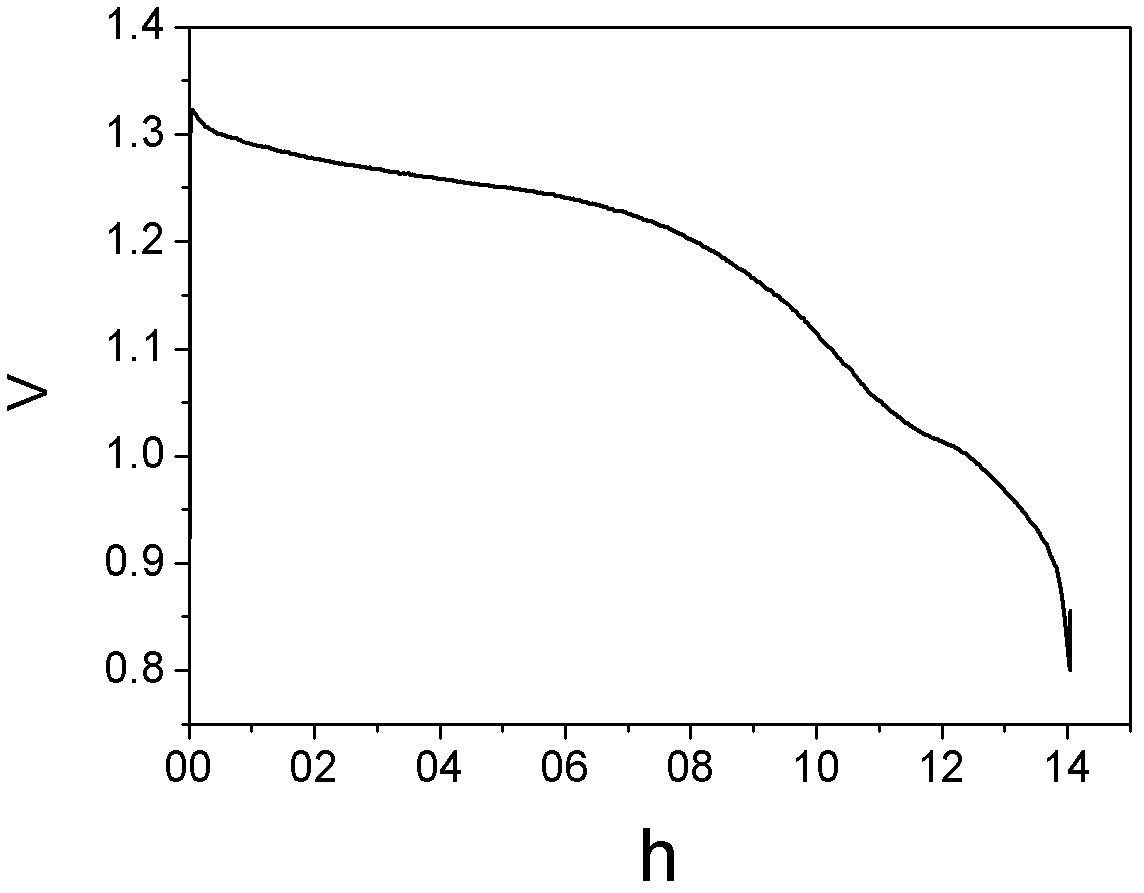

Embodiment 2

[0062] (1) Weigh 1.4146g LaNi respectively 5 , 0.0863gMgH 2 , 0.0650g nickel foam, 1.0008g nickel hydroxide powder, LaNi 5 , MgH 2 , Hydroxynickel powder is 200 mesh powder after sieving;

[0063] (2) Then mix the powder evenly;

[0064] (3) Put the powder into the stuffing tank of the battery stamping system, the filling amount is half of the total amount of the above powder, and then put a piece of nickel foam with a diameter of 10mm, and then put the remaining half of the powder into the tablet , to obtain a disc with a diameter of 10mm, the test force selected during the tableting process was 15KN, and the pressure was kept for 2min;

[0065] (4) take out disc after sheet pressing is finished, then weld a section of long 10cm, wide nickel bar with 5mm with AC spot welding machine, make required negative plate;

[0066] (5) Wrap the disc welded with nickel strips with diaphragm paper with a length of 7.5cm and a width of 4cm, and put Ni(OH) on both sides of the diaphra...

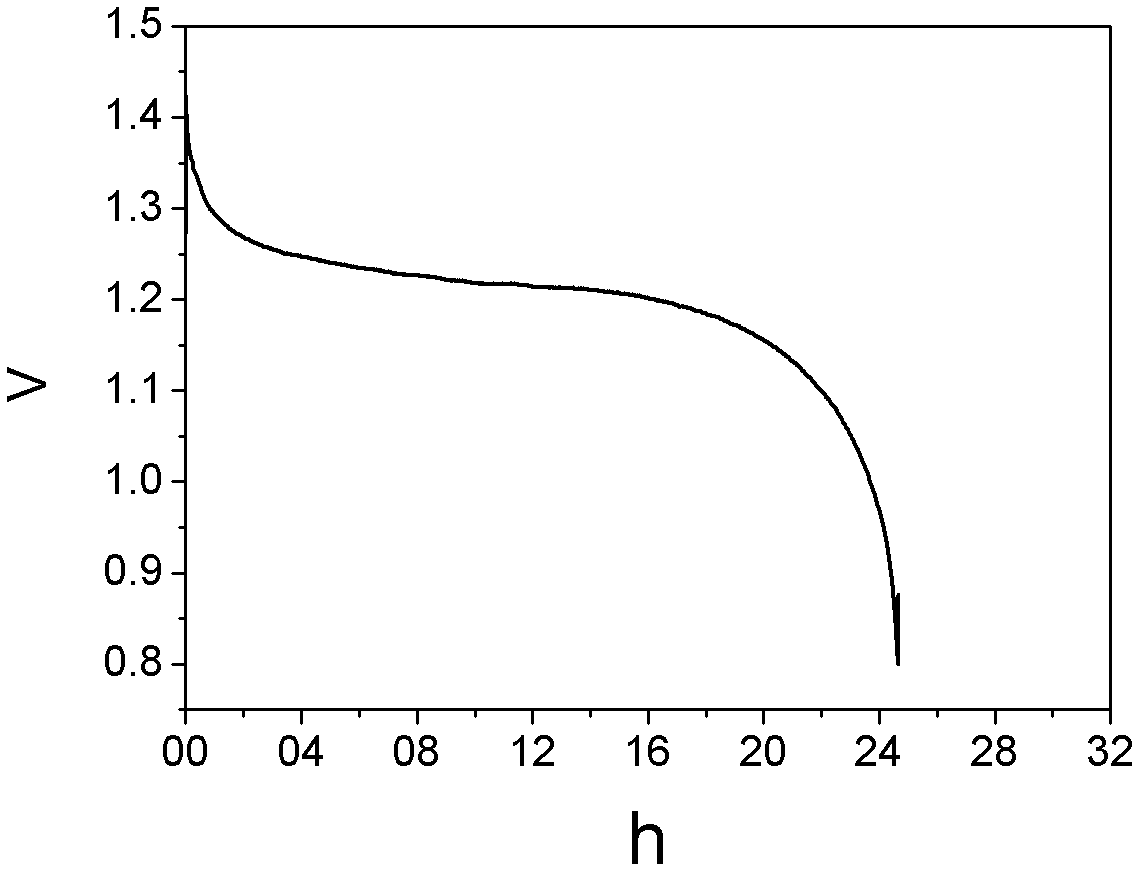

Embodiment 3

[0070] (1) Weigh 1.2679gLaNi respectively 5 , 0.2316gMgH 2 , 0.0656g nickel foam, 2.0004g nickel hydroxide powder, LaNi 5 , MgH 2 , Hydroxynickel powder is 200 mesh powder after sieving;

[0071] (2) Then mix the powder evenly;

[0072] (3) Put the powder into the stuffing tank of the battery stamping system, the filling amount is half of the total amount of the above powder, and then put a piece of nickel foam with a diameter of 10mm, and then put the remaining half of the powder into the tablet , to obtain a disc with a diameter of 10mm, the test force selected during the tableting process was 15KN, and the pressure was kept for 2min;

[0073] (4) Take out the disc after the sheet pressing is completed, then weld a section of nickel strip with a length of 10cm and a width of 5mm with an AC electric welding machine to make the required negative electrode sheet;

[0074] (5) Wrap the disc welded with nickel strips with diaphragm paper with a length of 7.2cm and a width of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com