Embedded type wiring terminal sealing cover for large aluminium electrolytic capacitors

A technology for aluminum electrolytic capacitors and terminals, applied in capacitor terminals, capacitor shells/packages, and capacitor components, etc., which can solve the problems of high positive and negative short-circuit risks of capacitors, increase of equivalent series inductance of capacitors, and increase of loop space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

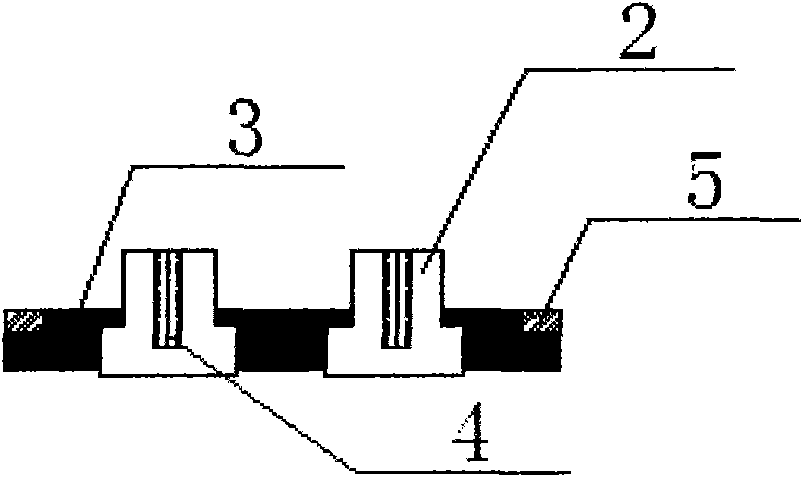

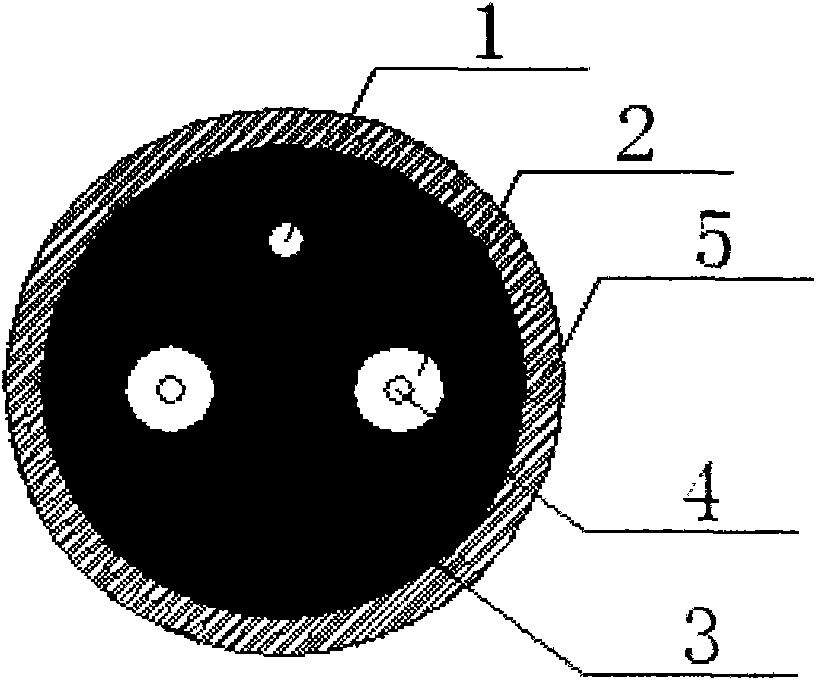

[0015] Example 1: Increase the diameter of the wiring terminal 2 inside the insulating material body 3 of the sealing terminal cover, reduce the distance between the positive and negative terminals, and start the pressure valve 1 for the wiring terminal post 2 protruding from the sealing insulating material body 3 Cover with the same insulating material as the sealing insulating material plate body 3 within a safe distance. It should be noted that the surface distance between the positive and negative terminal 2 should be greater than the creepage distance. As a result, the enclosed space between the terminal posts is reduced, which reduces the equivalent series inductance (ESL) value. And remove the risk of positive and negative short circuit caused by splashing electrolyte when the pressure valve is activated (such as Figure 2a , Figure 2b ).

Embodiment 2

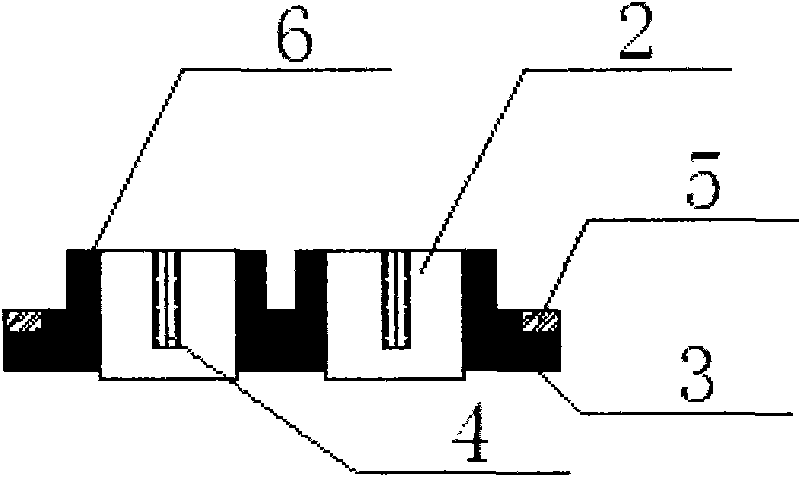

[0016] Example 2: Increase the diameter of the terminal 2 inside the insulating material body 3 of the sealing terminal cover plate, reduce the distance between the positive and negative terminals, and set the connection terminal 2 protruding from the insulating material body 3 of the sealing terminal in the safety room where the pressure valve 1 is activated. The same insulating material as the board body is used for overall coating within the distance. It should be noted that in order to ensure that the surface distance between the positive and negative terminals 2 is greater than the creepage distance, the insulating material covering body 6 is exposed or protruded from the terminal post 2. The diameter of the surface part needs to be reduced to ensure that the surface distance between the positive and negative terminals 2 on the surface is greater than the creepage distance. As a result, the enclosed space between the terminal posts is reduced, which reduces the equivalent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com