Manufacturing method of lead-acid battery negative grid

A technology of lead-acid batteries and manufacturing methods, applied in the direction of electrode carriers/collectors, etc., can solve the problems of increased number of parts, reduced reliability, cumbersome processes, etc., to reduce the scrap rate, ensure the strength of the grid, and ensure the quality of electroplating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The manufacturing method of the lead-acid storage battery negative grid comprises the following steps:

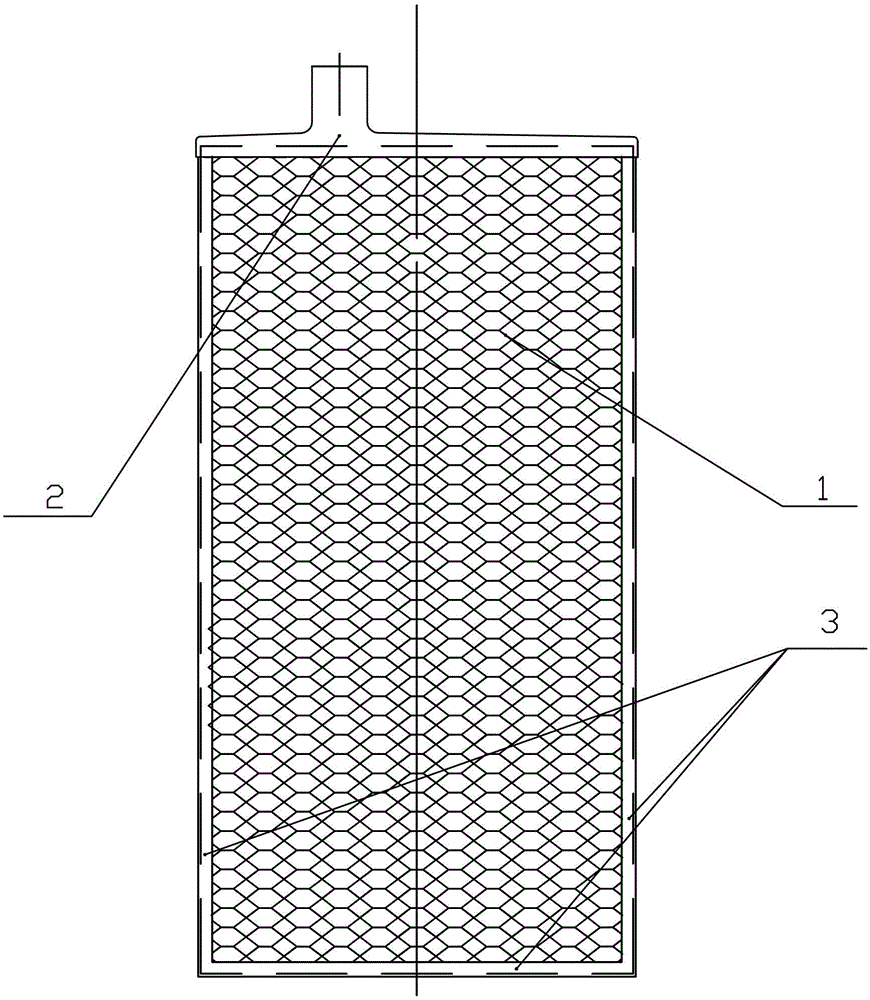

[0020] a. Pull the copper plate into a mesh shape to form a copper expanded mesh 1, and cut the copper expanded mesh 1 into a rectangular structure;

[0021] b. Place the copper expanded mesh 1 in the mold, then heat the lead-antimony alloy to 400°C and inject it into the mold cavity to form the copper expanded mesh 1 with the lugs 2;

[0022] c. Electroplate lead on the surface of the copper expanded mesh 1 with the plate lug 2, and form a layer of lead plating layer with a thickness of 5 μm on the surface of the copper expanded mesh 1;

[0023] d. Place the lead-plated copper expanded mesh 1 in the mold, inject polyvinyl chloride plastic at the other end of the copper expanded mesh 1 in the width direction and both ends in the length direction, and the injection molding temperature is 260° C. to form a plastic frame 3 .

[0024] After the plastic frame 3 is inject...

Embodiment 2

[0026] The manufacturing method of the lead-acid storage battery negative grid comprises the following steps:

[0027] a. Pull the copper plate into a mesh shape to form a copper expanded mesh 1, and cut the copper expanded mesh 1 into a rectangular structure;

[0028] b. Place the copper expanded mesh 1 in the mold, then heat the lead-calcium alloy to 500°C and inject it into the mold cavity to form the copper expanded mesh 1 with the lugs 2;

[0029] c. Electroplate lead on the surface of the copper expanded mesh 1 with the plate lug 2, and form a layer of lead plating layer with a thickness of 25 μm on the surface of the copper expanded mesh 1;

[0030] d. Place the lead-plated copper expanded mesh 1 in the mold, inject polyvinyl chloride plastic at the other end of the copper expanded mesh 1 in the width direction and both ends in the length direction, and the injection molding temperature is 330° C. to form a plastic frame 3 .

[0031] After the plastic frame 3 is inject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com