Fluorocarbon modified styrene-acrylic coating, and preparation method thereof

A technology of fluorocarbon modification and styrene-acrylic, which is applied in the direction of anti-corrosion coatings and coatings, and can solve the problems of high weather resistance, high chemical corrosion resistance, water resistance, scrub resistance and poor artificial aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

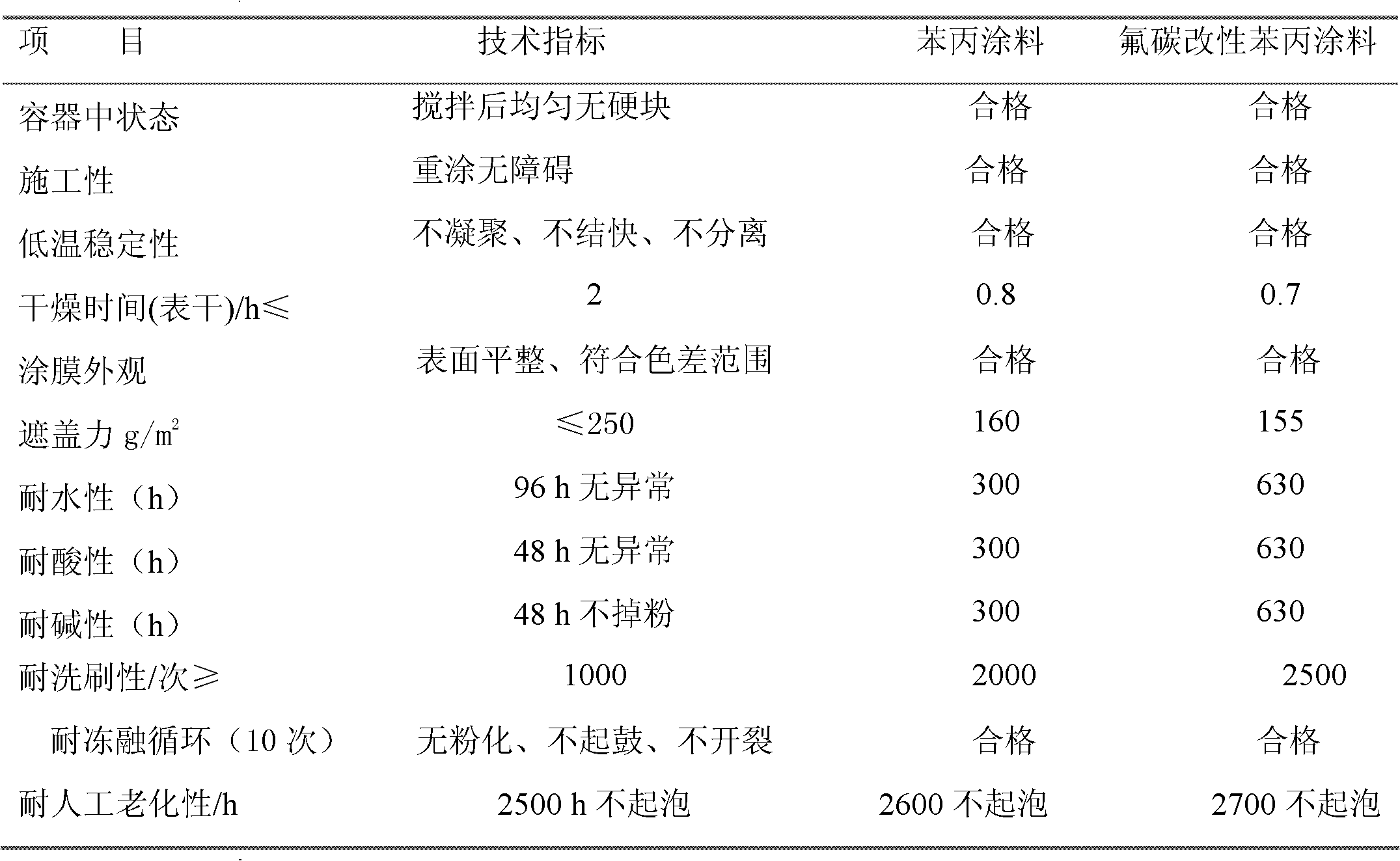

Examples

Embodiment 1

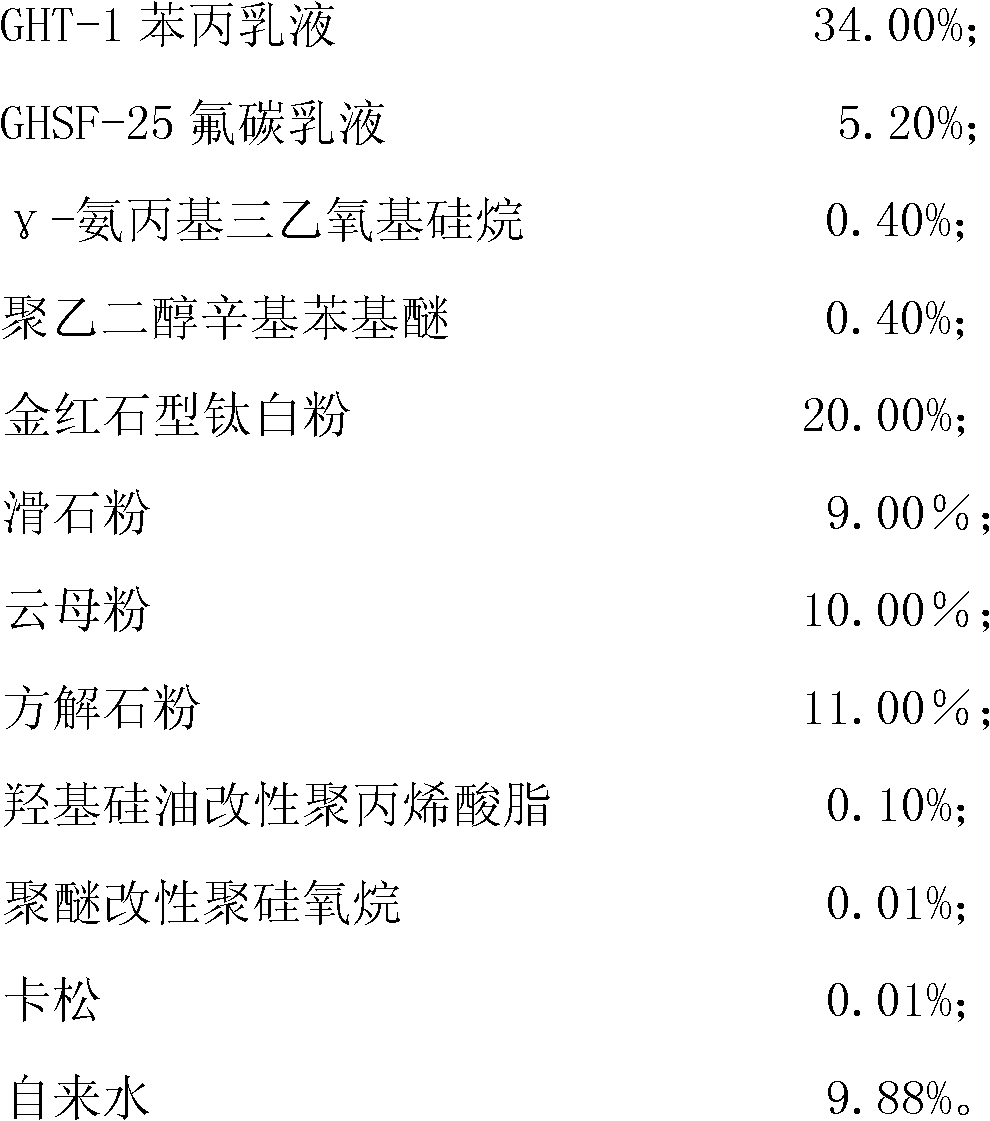

[0016] 1. Formula by mass percentage

[0017]

[0018] 2. Preparation method

[0019] Step 1. Add GHT-1 styrene-acrylic emulsion into a four-necked bottle, stir and raise the temperature to 73°C, slowly add GHSF-25 fluorocarbon emulsion, and at the same time slowly add γ-aminopropyltriethoxysilane, until the γ- -After aminopropyltriethoxysilane, add polyethylene glycol octylphenyl ether, hydroxyl silicone oil modified polyacrylate, polyether modified polysiloxane, and Cathone respectively, and the temperature is controlled at 76°C for reaction Half an hour later, the temperature was lowered and the material was discharged to obtain a fluorocarbon modified styrene-acrylic emulsion.

[0020] Step 2. Add water into the mixing tank, start the mixer, add rutile titanium dioxide and stir evenly; then add the fluorocarbon modified styrene-acrylic emulsion modified in step 1 and stir evenly, then add talcum powder, mica powder, and calcite respectively The powder is stirred evenl...

Embodiment 2

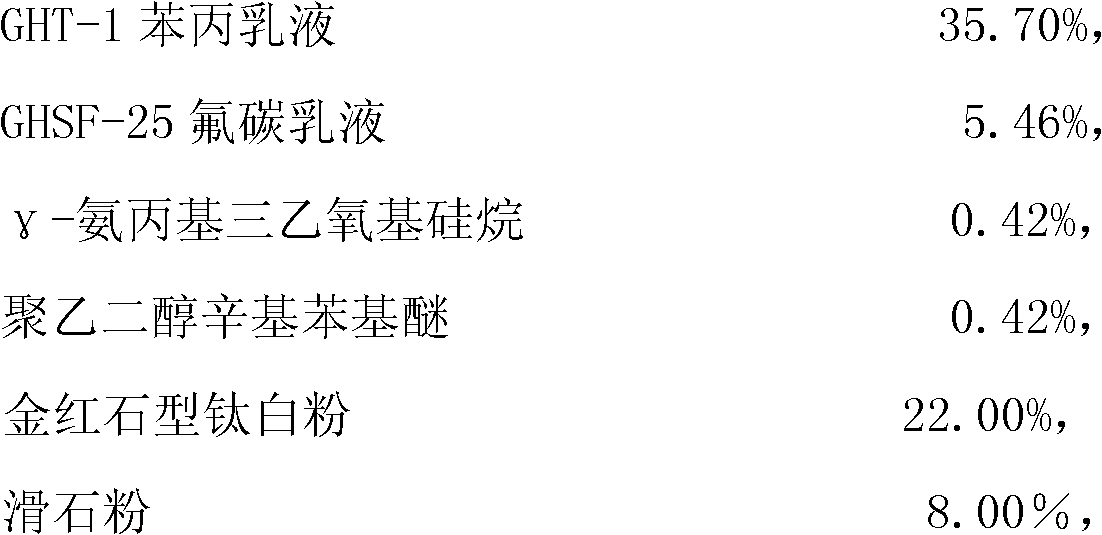

[0026] 1. Formula by mass percentage

[0027]

[0028]

[0029] 2. Preparation method

[0030] Step 1. Add GHT-1 styrene-acrylic emulsion into a four-necked bottle, stir and raise the temperature to 74°C, slowly add GHSF-25 fluorocarbon emulsion, and at the same time slowly add γ-aminopropyltriethoxysilane, until the γ- -After aminopropyltriethoxysilane, add polyethylene glycol octylphenyl ether, hydroxyl silicone oil modified polyacrylate, polyether modified polysiloxane, and Cathone respectively, and the temperature is controlled at 77°C for reaction Half an hour later, the temperature was lowered and the material was discharged to obtain a fluorocarbon modified styrene-acrylic emulsion.

[0031] Step 2. Add water into the mixing tank, start the mixer, add rutile titanium dioxide and stir evenly; then add the fluorocarbon modified styrene-acrylic emulsion modified in step 1 and stir evenly, then add talcum powder, mica powder, and calcite respectively The powder is s...

Embodiment 3

[0037] 1. Formula by mass percentage

[0038]

[0039] 2. Preparation method

[0040] Step 1. Add GHT-1 styrene-acrylic emulsion into a four-necked bottle, stir and raise the temperature to 75°C, slowly add GHSF-25 fluorocarbon emulsion, and at the same time slowly add γ-aminopropyltriethoxysilane, until the addition of γ -After aminopropyltriethoxysilane, add polyethylene glycol octylphenyl ether, hydroxyl silicone oil modified polyacrylate, polyether modified polysiloxane, and Cathone respectively, and the temperature is controlled at 78°C for reaction Half an hour later, the temperature was lowered and the material was discharged to obtain a fluorocarbon modified styrene-acrylic emulsion.

[0041] Step 2. Add water into the mixing tank, start the mixer, add rutile titanium dioxide and stir evenly; then add the fluorocarbon modified styrene-acrylic emulsion modified in step 1 and stir evenly, then add talcum powder, mica powder, and calcite respectively The powder is st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com