Ferric oxide pigment composition containing phosphate auxiliary ingredients and preparation method of ferric oxide pigment composition

A technology of iron oxide pigments and phosphate esters, applied in the direction of pigment paste, etc., can solve the problems of weak dispersion ability, low tinting power, large color paste particles, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific examples 1-8 and comparative examples 1-8.

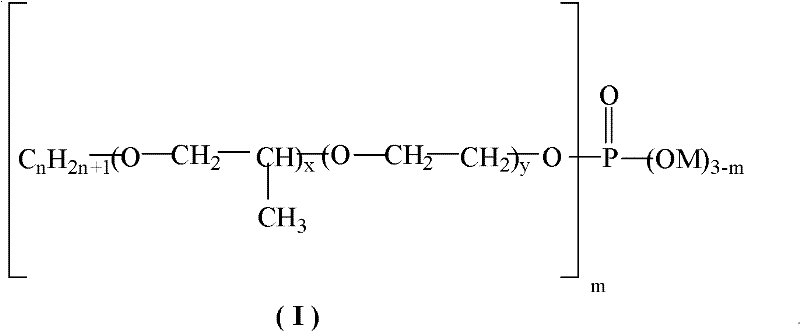

[0035] The anionic phosphate ester dispersant used in Examples 1 to 8 has the following structure:

[0036] Dispersant b-1:

[0037]

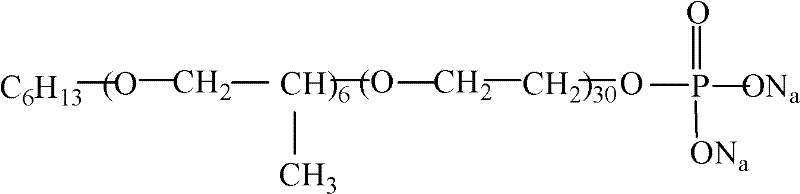

[0038] Dispersant b-2:

[0039]

[0040] Common dispersants used in Comparative Examples 1-8 have the following structure:

[0041] Dispersant b-3:

[0042] The molecular weight is the AB block type styrene-maleic anhydride resin of 16000;

[0043] Dispersant b-4:

[0044]

[0045] The concrete preparation steps of embodiment 1~8 and comparative example 1~8 are as follows:

[0046] (1) Reserve 10wt.% of the total amount of deionized water, and disperse 90wt.% of the total amount of deionized water, dispersant, wetting agent and functional additives in a disperser at a speed of 500-800r / min 15 to 20 minutes to obtain the premixed solution;

[0047] (2) Adjust the rotational speed of the disperser to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com