Sound-attenuating and wear-resistant polyformaldehyde material and preparation method thereof

A technology of polyoxymethylene material and polyoxymethylene resin, which is applied in the field of sound-absorbing and wear-resistant polyoxymethylene materials and its preparation, can solve the problems of high friction coefficient and high noise, and achieve the effects of low cost, high benefit and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

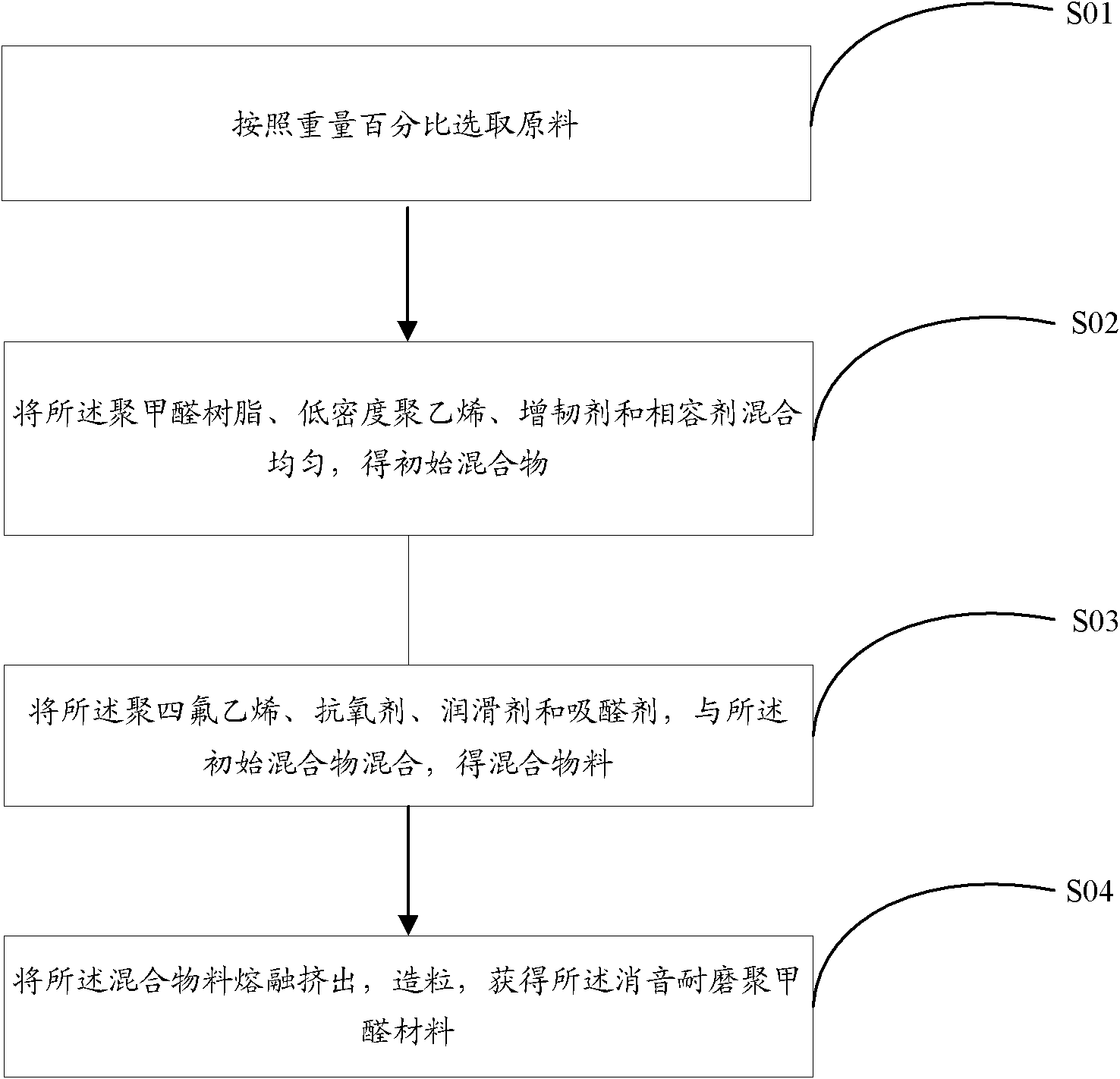

[0040] see figure 1 , showing a method for preparing a sound-absorbing and wear-resistant polyoxymethylene material according to an embodiment of the present invention, the method includes the following steps:

[0041] S01: Weigh each component according to the formula of the above-mentioned sound-absorbing and wear-resistant polyoxymethylene material;

[0042] S02: uniformly mixing the polyoxymethylene resin, low-density polyethylene, toughening agent and compatibilizer to obtain an initial mixture;

[0043] S03: Mix the polytetrafluoroethylene, antioxidant, lubricant and aldehyde absorbent with the initial mixture to obtain a mixed material;

[0044] S04: Melt-extrude the mixed material and granulate to obtain the sound-absorbing and wear-resistant polyoxymethylene material.

[0045] In step S01, all materials are weighed accurately, accurate to 0.001 kg. The sound-absorbing and wear-resistant polyoxymethylene material and the preferred content and types of each component...

Embodiment 1

[0052] The components and weight percentages of the sound-absorbing and wear-resistant polyoxymethylene material of the present embodiment are:

[0053] Polyoxymethylene resin 69%;

[0054] Low density polyethylene 7%;

[0055] Toughener 5%;

[0056] PTFE 15%;

[0057] Compatibilizer 3%;

[0058] Antioxidant 0.3%;

[0059] Lubricant 0.2~0.6%;

[0060] Aldehyde absorbent 0.2-0.6%.

[0061]Among them, the polyoxymethylene resin is a copolymerized POM, produced by Yuntianhua Company, and the trade name is M90; the low-density polyethylene is selected from relative density 0.91-0.929, produced by Sinopec, and the trade name is LDPE 7042; the toughening agent thermoplastic elastomer TPU is polyether type, The hardness is 85A, produced by BASF in Germany, and the trade name is 1185A; the polytetrafluoroethylene is made of micro-powder type, the powder material is 150 mesh, and it is produced by Daikin, Japan, and the trade name is L-5; the compatibilizer is EVA resin, the VA c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com