Method for synthesizing allyl fatty alcohol-polyoxyethylene ether or allyl alkylphenol ethoxylate

A technology of allyl alkylphenol polyoxyethylene ether and alkylphenol polyoxyethylene ether, which can be applied in ether preparation, ester reaction preparation ether, organic chemistry, etc., can solve the problem of difficult separation of phase transfer catalyst, increase reaction cost, Environmental problems and other problems, to achieve the effect of reducing solvent removal units, low cost and mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

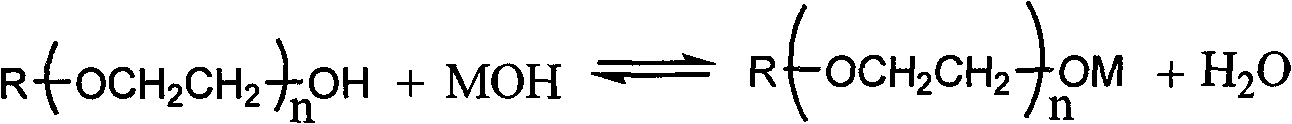

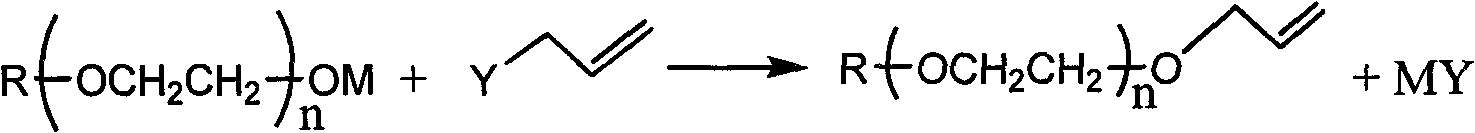

Method used

Image

Examples

Embodiment 1

[0032] The first step reaction: put 200 grams of fatty alcohol polyoxyethylene ether AEO-7 (molecular weight 501) and 22 grams of solid sodium hydroxide (particle size 1mm) into a 500ml stainless steel autoclave, the molar ratio is 1: 1, and feed simultaneously Stir the materials, close the reactor after feeding, replace the air in the reactor with nitrogen, start the vacuum system after the replacement, keep the vacuum of the reactor at 0.085MPa, keep stirring the materials during this process, and raise the temperature of the reactor to 200°C , after reacting for 5 hours, stop heating, cool to room temperature, and close the vacuum system;

[0033] The second step reaction: add 39 grams of allyl chloride dropwise to the above reaction kettle, the molar ratio of fatty alcohol polyoxyethylene ether or alkylphenol polyoxyethylene ether to allyl chloride is 1:1, during the dropwise addition process Stir the material continuously, after the dropwise addition, the reaction exother...

Embodiment 2

[0036] The first step reaction: 200 grams of alkylphenol polyoxyethylene ether NP-8 (molecular weight 520) and 12 grams of solid lithium hydroxide (particle size 0.1mm) were dropped into a 500ml stainless steel autoclave, and the molar ratio was 1: 1.3. Stir the material at the same time as feeding, seal the reactor after feeding, replace the air in the reactor with nitrogen, start the vacuum system after the replacement, keep the vacuum of the reactor at 0.1MPa, keep stirring the materials during this process, and the temperature of the reactor rises to 140°C, after 3 hours of reaction, stop heating, cool to room temperature, and turn off the vacuum system;

[0037] The second step reaction: add 60 grams of allyl bromide dropwise to the above reaction kettle, the molar ratio of fatty alcohol polyoxyethylene ether or alkylphenol polyoxyethylene ether to allyl bromide is 1: 1.3, during the dropwise addition process Stir the material continuously, after the dropwise addition, th...

Embodiment 3

[0040] The first step reaction: 200 grams of alkylphenol polyoxyethylene ether TX-10 (molecular weight 601) and 28 grams of solid potassium hydroxide (particle diameter 0.01mm) were dropped into a 500ml stainless steel autoclave, and the molar ratio was 1: 1.5. Stir the material at the same time as feeding, seal the reactor after feeding, replace the air in the reactor with nitrogen, start the vacuum system after the replacement, keep the vacuum of the reactor at 0.1MPa, keep stirring the materials during this process, and the temperature of the reactor rises to 70°C, after 1 hour of reaction, stop heating, cool to room temperature, and turn off the vacuum system;

[0041]The second step reaction: add 38 grams of allyl chloride dropwise to the above reaction kettle, the molar ratio of fatty alcohol polyoxyethylene ether or alkylphenol polyoxyethylene ether to allyl chloride is 1: 1.5, and the dripping process continues Stir the material, drop the reaction heat to 100°C after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com