Preparation method of polymer dispersed liquid crystal film

A technology for dispersing liquid crystals and polymers. It is applied in liquid crystal materials, chemical instruments and methods, instruments, etc., and can solve the problems of not being widely used and large equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

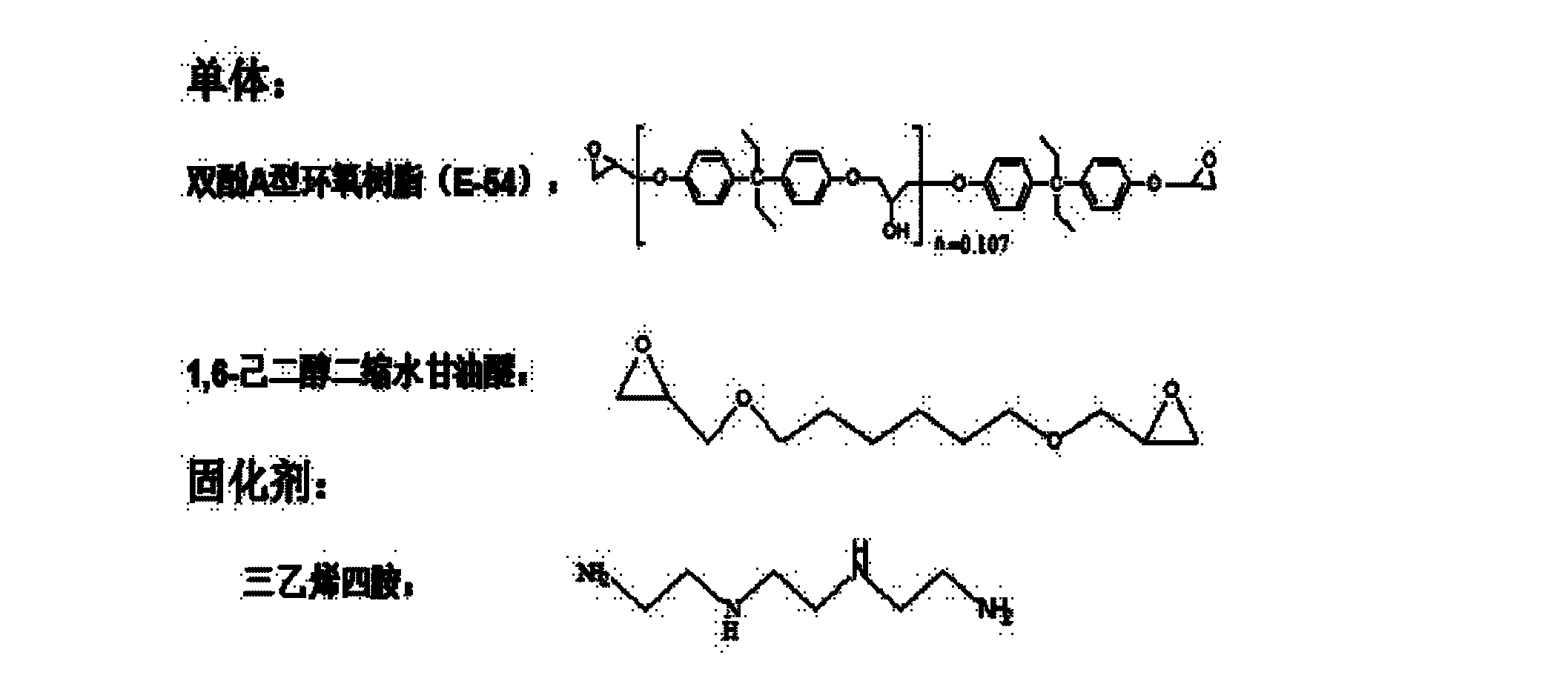

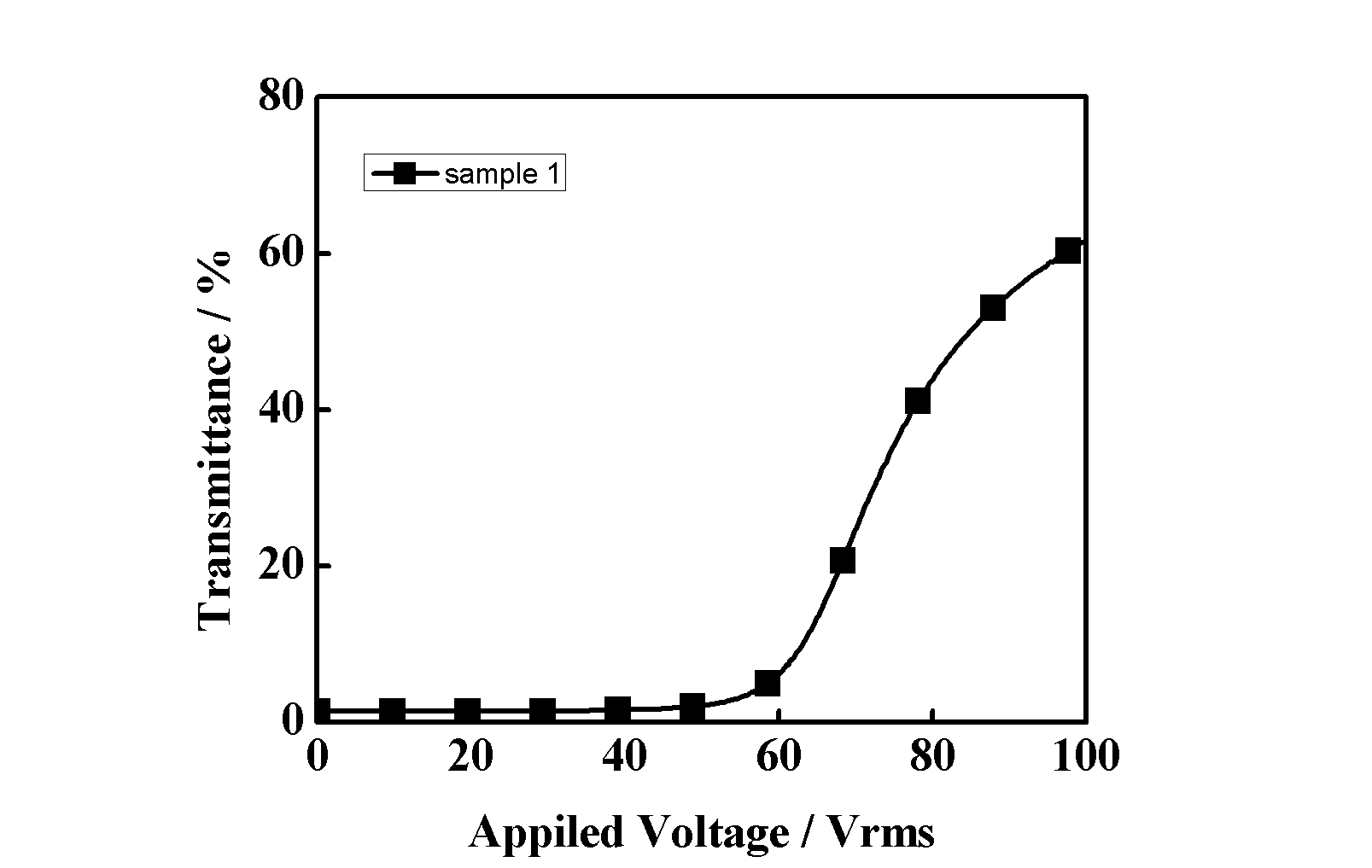

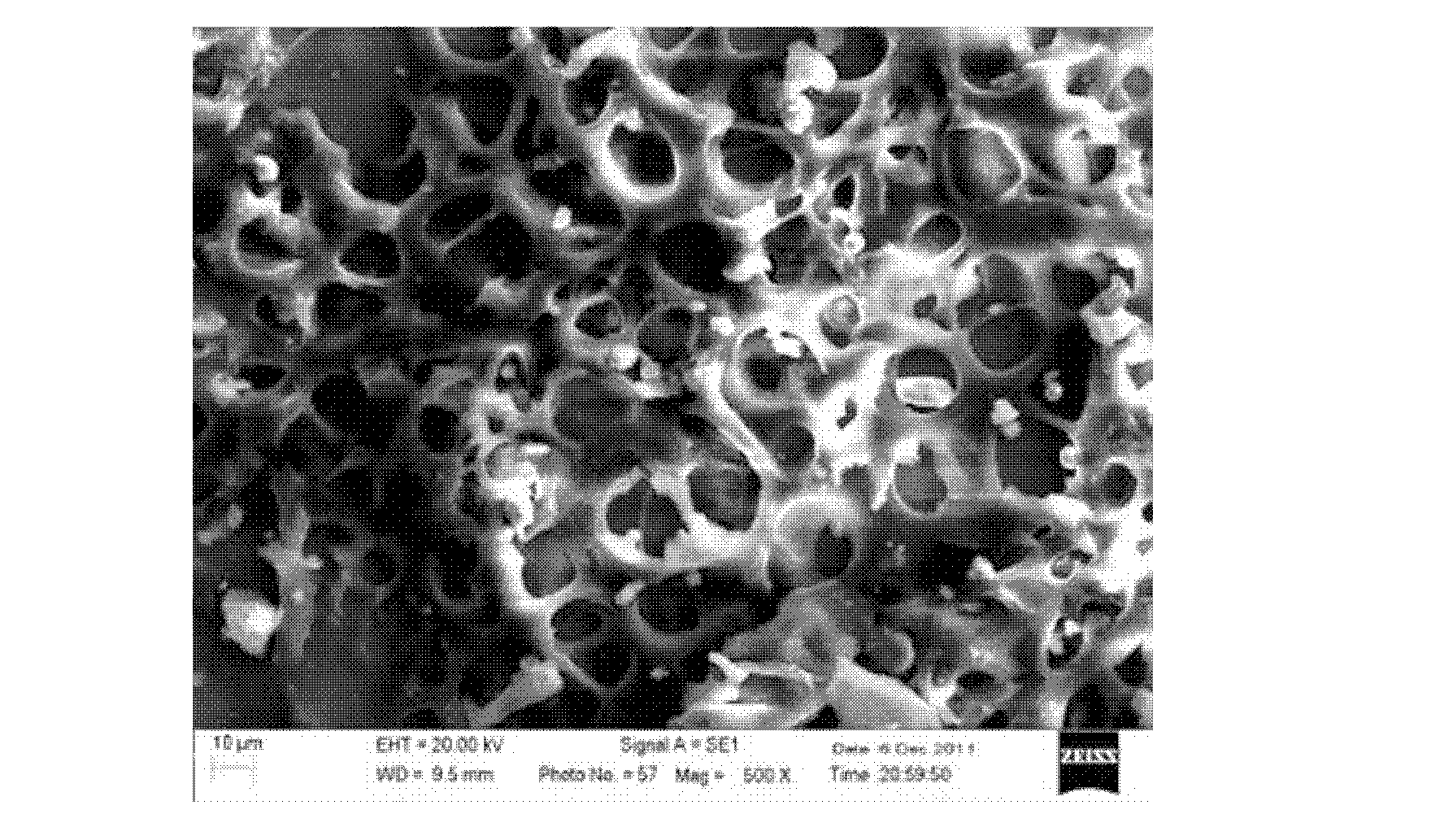

[0019] The thermally polymerizable monomer selected is bisphenol A epoxy resin (E-54), which is mixed with aliphatic polyamine curing agent triethylenetetramine (TETA) according to the mass ratio of 1.00:0.13 to form a polymer Monomer system. Then the nematic liquid crystal SLC1717 (T NI =365.2K,n o =1.519,n e =1.720) into the polymerized monomer system, the content of SLC1717 added accounted for 70.0% of the total mass of the system; glass microspheres with a diameter of 15.0 microns were added to the polymerized monomer system, and the content of glass microspheres accounted for the total mass of the system 0.5%. Under heating conditions (about 50.0°C), the system clarifies to the clearing point and forms an isotropic liquid. Use a vortex shaker to mix the system evenly. After the system reaches the clearing point, apply it between two transparent plastic conductive films coated with indium tin oxide (ITO), and press it to about 15.0 microns with a roller. After uniform...

Embodiment 2

[0023] The thermally polymerizable monomers selected are bisphenol A-type epoxy resin (E-54) and aliphatic glycidyl ether epoxy resin 1,6-hexanediol diglycidyl ether (HGDE), and according to the mass ratio (E-54: HGDE=2.0:8.0) Mix the two monomers evenly, and then mix the mixed monomers with aliphatic polyamine curing agent triethylenetetramine (TETA) at a mass ratio of 1.00:0.13 to form Polymerized monomer system. Then the nematic liquid crystal SLC1717 (T NI =365.2K,n o =1.519,n e=1.720) into the polymerized monomer system, the content of SLC1717 added accounted for 75.0% of the total mass of the system; glass microspheres with a diameter of 15.0 microns were added to the polymerized monomer system, and the content of glass microspheres accounted for the total mass of the system 0.5%. Under heating conditions (about 50.0°C), the system reaches the clearing point and forms an isotropic liquid. Use a vortex shaker to mix the system evenly. After the system reaches the cle...

Embodiment 3

[0027] The thermally polymerizable monomers selected are bisphenol A-type epoxy resin E-54 and aliphatic glycidyl ether epoxy resin 1,6-hexanediol diglycidyl ether (HGDE), and according to the mass ratio (E -54:HGDE=1.0:9.0) Mix the two monomers evenly, and then mix the mixed monomers with the aliphatic polyamine curing agent triethylenetetramine (TETA) at a mass ratio of 1.00:0.13 to form a polymeric monomer body system. Then the nematic liquid crystal SLC1717 (T NI =365.2K,n o =1.519,n e =1.720) into the polymerized monomer system, the content of SLC1717 added accounted for 75% of the total mass of the system; glass microspheres with a diameter of 15 microns were added to the polymerized monomer system, and the content of glass microspheres accounted for the total mass of the system 0.5%. Under heating conditions (about 50°C), the system reaches the clearing point and forms an isotropic liquid. Use a vortex shaker to mix the system evenly. After the system reaches the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com