Method for sulfonating pectin

A pectin and sulfonation technology, applied in the field of polymers, can solve the problems of less data and immature pectin, and achieve the effect of mild method, good anticoagulation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

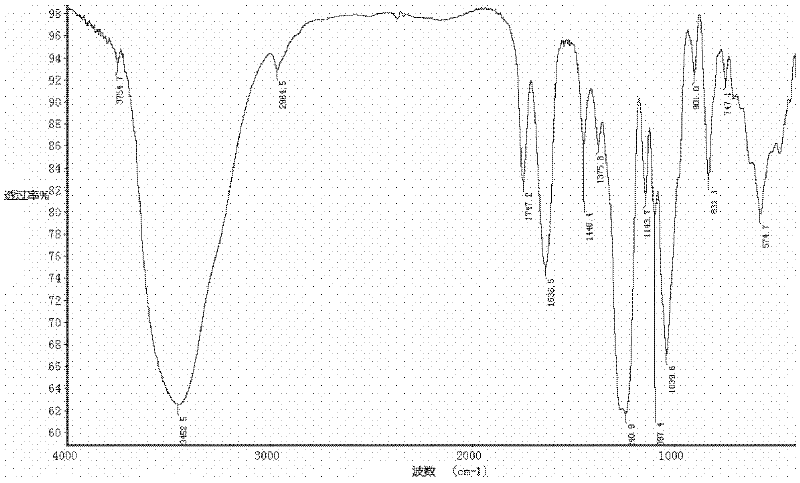

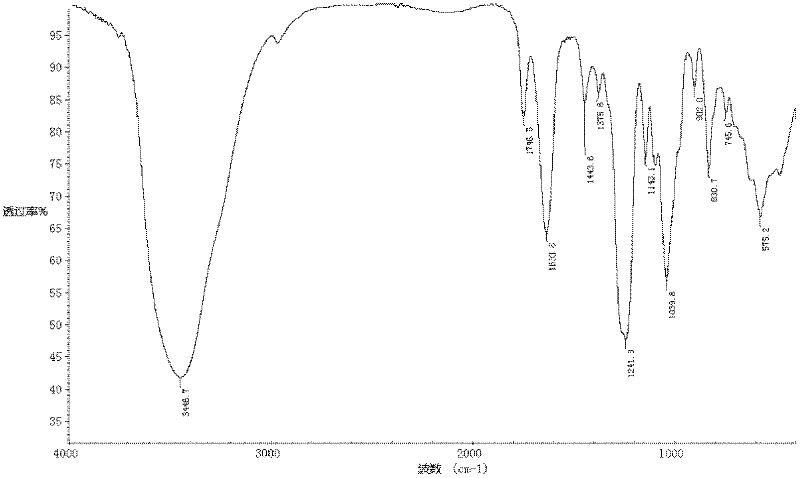

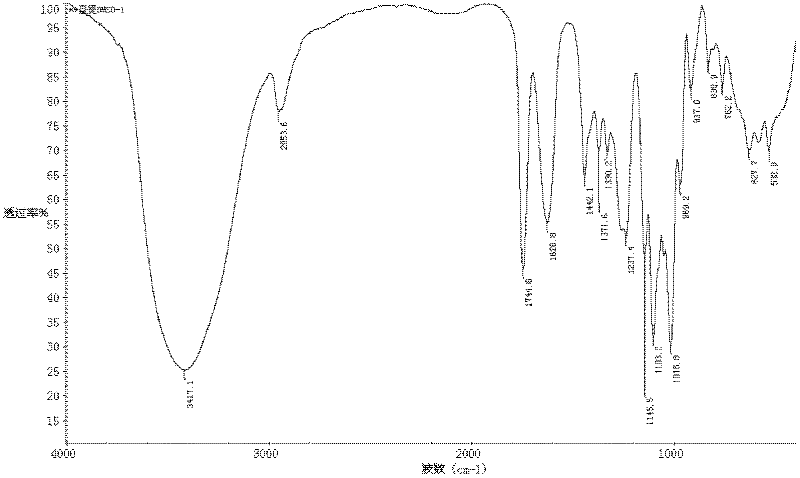

Image

Examples

Embodiment 1

[0041] Embodiment 1, a kind of method of pectin sulfonation, carries out following steps successively:

[0042] (1) Preparation of esterification reagent: 2 g of sulfur trioxide-pyridine complex was dissolved in 4 ml of anhydrous dimethyl sulfoxide to obtain sulfonation reagent;

[0043] (2) Preparation of self-extracting pectin suspension:

[0044] Dried citrus peels (moisture content ≤ 90%) are pulverized into powder (passed through a 60-mesh sieve), then soaked in 30 times the volume of water overnight (soaked for 12 hours), centrifuged at a speed of 3000r / min for 40min, The resulting supernatant was precipitated by adding 3 times the volume of absolute ethanol. Water-soluble pectin can be obtained by repeatedly precipitating twice with the same amount of ethanol, and after drying (drying at 50°C to constant weight), citrus pectin can be obtained.

[0045] Put 200 mg of citrus pectin into 10 ml of anhydrous dimethyl sulfoxide and stir for 0.5 hour to obtain a pectin suspe...

Embodiment 2

[0051] Embodiment 2, a kind of preparation method of pectin sulfonation, carries out following steps successively:

[0052] (1) Preparation of esterification reagent: 2 g of sulfur trioxide-pyridine complex was dissolved in 4 ml of anhydrous dimethyl sulfoxide to obtain sulfonation reagent;

[0053] (2) Preparation of commercial pectin suspension:

[0054] First commercial citrus pectin (purchasable from sigma company) is purified by fractional precipitation with ethanol and acetone to obtain purified commercial pectin; details are as follows:

[0055] Take 50ml of commercial citrus pectin, pour it into 50ml of absolute ethanol, ultrasonically dissolve it, and enter the centrifuge at a speed of 3000r / min for 40 minutes; pour off the ethanol layer in the upper layer obtained after centrifugation, take the lower layer and add 50ml of precipitate 80% (volume concentration) of ethanol, after ultrasonic dissolution, enter the centrifuge and centrifuge at a speed of 3000r / min for 4...

Embodiment 3

[0062] Embodiment 3, a kind of preparation method of pectin sulfonation, carries out following steps successively:

[0063] (1), the preparation of esterification reagent:

[0064] Dissolve 2g of sulfur trioxide-pyridine complex in 4ml of anhydrous dimethyl sulfoxide to obtain a sulfonation reagent;

[0065] (2) Put 200 mg of citrus pectin into 10 ml of ultrapure water, stir for 0.5 hour, and completely dissolve the pectin; obtain a pectin solution.

[0066] The preparation method of citrus pectin is with embodiment 1.

[0067] Above-mentioned pectin solution is crossed gel chromatography column, specifically as follows:

[0068] Use Sephacryl S-300column (1.6cm×100cm) Sephadex column, use pH3.5 hydrochloric acid solution as mobile phase, flow rate is 0.5ml / min, start to collect after 160 minutes, collect to 750min, after 800 minutes Stop elution. Obtain the collection fluid.

[0069] Add triethylamine (TBA) dropwise to the above collection solution until the pH is 6.0-6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com