Method for preparing high-purity baicalin

A baicalin, high-purity technology, applied in the field of preparation of high-purity baicalin, can solve the problems of cumbersome preparation process, expensive equipment, capillary blockage, etc., and achieve the effect of high separation efficiency, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

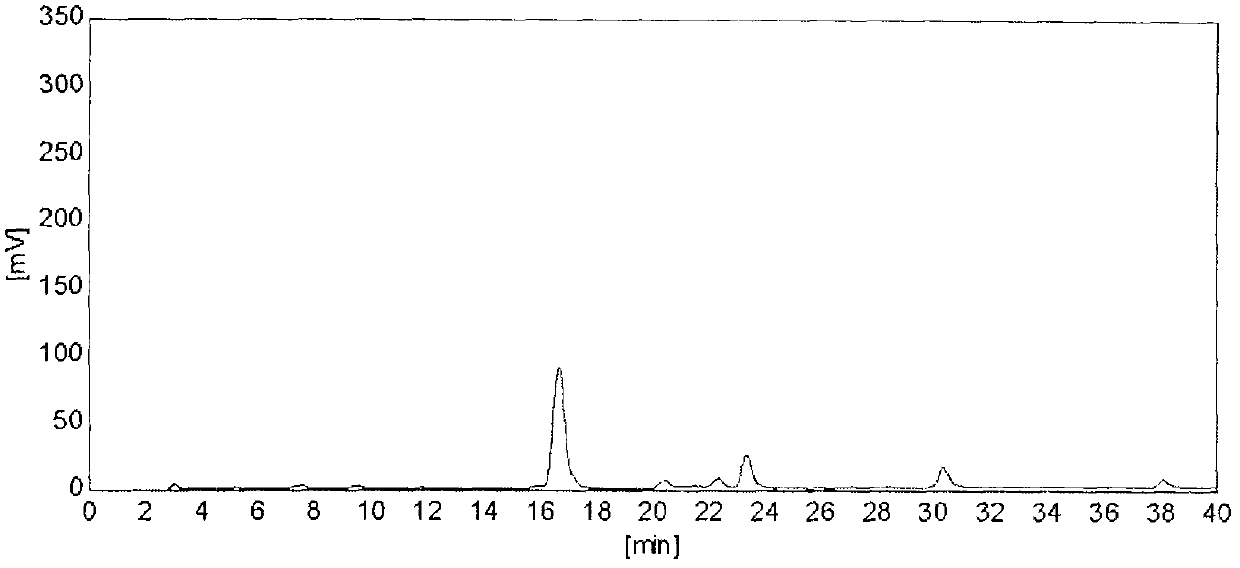

[0034] Take 100g of Scutellaria baicalensis, add 600mL of water, heat to 60°C for extraction, extract for 1 hour, extract 3 times, add the extract to the treated HPD-100 macroporous adsorption resin column for adsorption, and elute with 5BV of water. Discard, then elute with 5BV10% ethanol water, recover the solvent, discard the residue, then elute with 40% ethanol water, collect 40% eluate (5BV), concentrate under reduced pressure, and freeze-dry to obtain crude baicalin 6.69g, the crude product is recrystallized with ethanol / water / acetic acid (4 / 6 / 1) to obtain baicalin 4.93g, the content of baicalin is 98.60% through HPLC analysis, as attached Figure 4 shown.

Embodiment 2

[0036]Take 100g of Scutellaria baicalensis, add 700mL of water, heat to 70°C for extraction, extract for 2 hours, extract 3 times, add the extract to the treated HPD-300 macroporous adsorption resin column for adsorption, and elute with 5BV of water. Discarded, then eluted with 5BV20% ethanol water, recovered the solvent, discarded the residue, then eluted with 50% ethanol water, collected 50% eluent (5BV), concentrated under reduced pressure, and freeze-dried to obtain crude baicalin 6.85 g, the crude product was recrystallized with ethanol / water / acetic acid (3:7:1) to obtain 5.12 g of baicalin, and the content of baicalin was 98.32% by HPLC analysis.

Embodiment 3

[0038] Take 100g of Scutellaria baicalensis, add 800mL of water, heat to 80°C for extraction, extract for 3 hours, extract 3 times, add the extract to the treated D-101 macroporous adsorption resin column for adsorption, and elute with 5BV of water. Discarded, then eluted with 5BV30% ethanol water, recovered the solvent, discarded the residue, then eluted with 60% ethanol water, collected 60% eluate (5BV), concentrated under reduced pressure, and freeze-dried to obtain crude baicalin 6.21g, this product was recrystallized with ethanol / water / acetic acid (2:8:1) to obtain 4.73g of baicalin, the content of baicalin was 99.10% by HPLC analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com