Two-piece ceramic bulb shell and manufacturing method thereof

A manufacturing method and blister technology, applied in electrical components, cold cathode manufacturing, electrode system manufacturing, etc., can solve problems affecting performance, difficult control, green body deformation, etc., achieve coaxiality guarantee, and increase bonding area , Guarantee the effect of bonding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

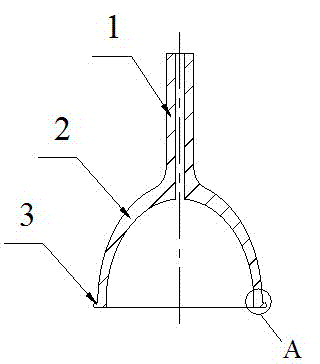

[0045] Embodiment 1, making a batch of 150W ellipsoidal two-piece ceramic blister

[0046] 1. According to the requirements, use spray granulated high-purity alumina to form a batch of blister blanks by isostatic pressing.

[0047]2. Configure a batch of slurry, the main component is high-purity alumina powder, add 3% glycerin, 4.5% terpineol, 2% dioctyl phthalate, 1% didecyl phthalate, 2% Epoxy resin, 0.3% polyamide wax, 0.25% hydrogenated castor oil, the viscosity of the test slurry is 32000mPa×S, and the prepared slurry is sealed and stored on a rotating table in a constant temperature box to rotate at a constant speed.

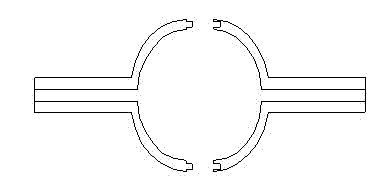

[0048] 3. Put the formed blank capillary down and the cavity joint ring up into the Figure 8 In the jig shown, a thin paste layer is printed on the surface of the bonding ring of the body cavity by using thin film printing technology, and the thickness of the paste layer is about 0.04mm.

[0049] 4. Take half of the green body with printed paste from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com