Method for improving overall performance of lateral stopper of rail vehicle and lateral stopper

A technology for lateral stoppers and rail vehicles, which is applied in the direction of the device for lateral relative movement between the undercarriage and the bogie, to achieve the effects of expanding the bonding area, improving the shear load bearing capacity, and expanding the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

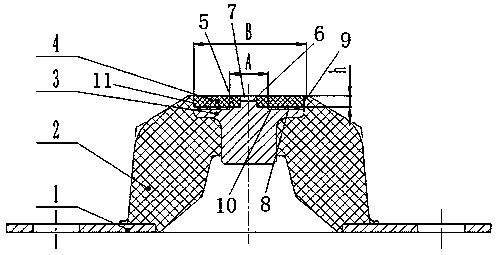

[0026] by attaching figure 2 with 3It can be seen that the present invention relates to a lateral stop with a hard stop, including a wear-resistant plate 4, a hard stop 3, a lateral stop rubber body 2 and a bottom plate 1, a wear-resistant plate 4, a hard stop 3, And the base plate 1 and the lateral stop rubber body 2 are integrally vulcanized and molded together to form a lateral stop of the bonding structure of the wear-resistant plate, the hard stop and the lateral stop rubber body.

[0027] The lateral stop of the described lateral stop rubber body bonding structure is to set a ring-shaped bonding boss 5 on the upper surface of the hard stop, and then set a positioning boss 6 on the bonding boss 5 At the same time, a central hole 7 is set in the center of the wear-resistant plate 4, and the size of the central hole 7 matches the positioning boss 6 on the hard stop 3; the bonding boss 5 and the positioning boss on the annular surface of the hard stop 3 The surface of the...

Embodiment 2

[0041] The principle of the second embodiment is the same as that of the first embodiment, except that the structure is slightly different. A horizontal stopper includes a wear-resistant plate 4, a hard stopper 3, a transverse stopper rubber body 2 and a bottom plate 1, which are wear-resistant Plate 4, hard stopper 3, bottom plate 1 and transverse stopper rubber body 2 are integrally vulcanized and molded together to form a transverse stopper with a bonding structure of wear-resistant plate, hard stopper and transverse stopper rubber body.

[0042] It is just that after the wear-resistant plate 4 and the hard stop 3 are bonded, a gap a is formed between the bottom surface of the wear-resistant plate and the upper end surface of the hard stop, and the width of the gap a is controlled at 1.5-2mm. The vulcanized rubber layer 10 formed of vulcanized rubber is used for bonding the upper and lower sides of the wear-resistant plate 4 and the hard stop 3 to increase the bonding streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com