Method for preparing 4A molecular sieves by doping bentonite with attapulgite

A technology of bentonite and attapulgite is applied in the field of preparing 4A molecular sieve, which can solve the problems of energy waste, large acid consumption, environmental pollution, etc., and achieve the effects of reducing waste, saving costs, and not requiring high equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

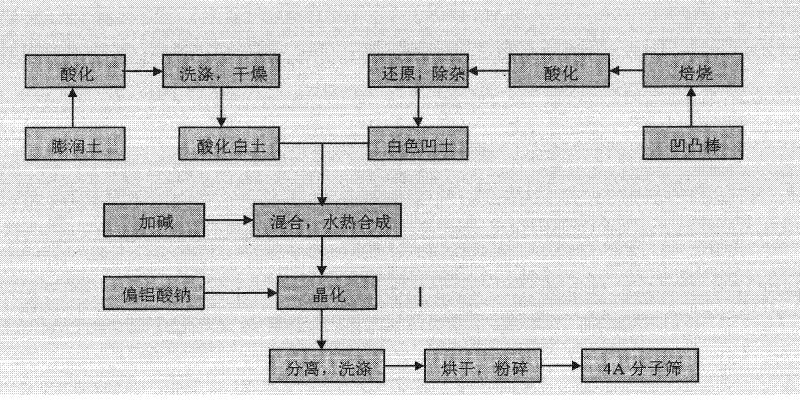

Method used

Image

Examples

Embodiment 1

[0025] 61.2ml of 98% concentrated sulfuric acid was dissolved in 38.8ml of distilled water to obtain 60% sulfuric acid. Take 30g of bentonite and put it in a beaker, add 90ml of 60% sulfuric acid into the beaker, place the beaker on a constant temperature magnetic stirrer, stir, and make it react at 90°C for 12h, after it settles and separates, discard the upper layer filtrate, and acidify the lower layer Wash the white clay until neutral, dry to obtain acidified white clay, and pass through a 200-mesh sieve.

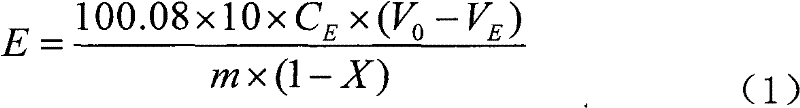

[0026] Dissolve 8.2ml of 98% concentrated sulfuric acid in 91.8ml of distilled water to obtain 8% sulfuric acid; dissolve 108g of oxalic acid in 892g of distilled water to obtain a 1.2mol / L oxalic acid solution; take 30g of attapulgite and place it in a muffle furnace Roast at 800°C for 1h, weigh 20g after cooling, add 160ml of 8% sulfuric acid, acidify at 60°C for 4h, wash until neutral after reaction, dry, add 500ml of 1.2mol / L oxalic acid and 1ml of titanium trichlor...

Embodiment 2

[0031] 61.2ml of 98% concentrated sulfuric acid was dissolved in 38.8ml of distilled water to obtain 60% sulfuric acid. Take 30g of bentonite and put it in a beaker, add 90ml of 60% sulfuric acid into the beaker, place the beaker on a constant temperature magnetic stirrer, make it react at 90°C for 12h, discard the upper layer filtrate after it settles and separate layers, and wash the lower layer with acidified clay To neutrality, dry to obtain acidified clay, and pass through a 200-mesh sieve.

[0032] Dissolve 8.2ml of 98% concentrated sulfuric acid in 91.8ml of distilled water to obtain 8% sulfuric acid; dissolve 108g of oxalic acid in 892g of distilled water to obtain a 1.2mol / L oxalic acid solution; take 30g of attapulgite and place it in a muffle furnace Roast at 800°C for 1h, weigh 20g after cooling, add 160ml of 8% sulfuric acid, acidify at 60°C for 4h, wash until neutral after reaction, dry, add 500ml of 1.2mol / L oxalic acid and 1ml of titanium trichloride after dryi...

Embodiment 3

[0037] 61.2ml of 98% concentrated sulfuric acid was dissolved in 38.8ml of distilled water to obtain 60% sulfuric acid. Take 30g of bentonite and put it in a beaker, add 90ml of 60% sulfuric acid into the beaker, place the beaker on a constant temperature magnetic stirrer, make it react at 90°C for 12h, discard the upper layer filtrate after it settles and separate layers, and wash the lower layer with acidified clay To neutrality, dry to obtain acidified clay, and pass through a 200-mesh sieve.

[0038] Dissolve 8.2ml of 98% concentrated sulfuric acid in 91.8ml of distilled water to obtain 8% sulfuric acid; dissolve 108g of oxalic acid in 892g of distilled water to obtain a 1.2mol / L oxalic acid solution; take 30g of attapulgite and place it in a muffle furnace Roast at 800°C for 1h, weigh 20g after cooling, add 160ml of 8% sulfuric acid, acidify at 60°C for 4h, wash until neutral after reaction, dry, add 500ml of 1.2mol / L oxalic acid and 1ml of titanium trichloride after dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com