Method for extracting selenium from nickel-molybdenum ore smelting fume by catalytic oxidation leaching-control potential reduction

A technology of catalytic oxidation and nickel-molybdenum ore, which is applied in the field of selenium extraction, can solve the problems of flying dust, polluting the environment, and high energy consumption, and achieves the effects of increased leaching rate, high utilization rate, and fast leaching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

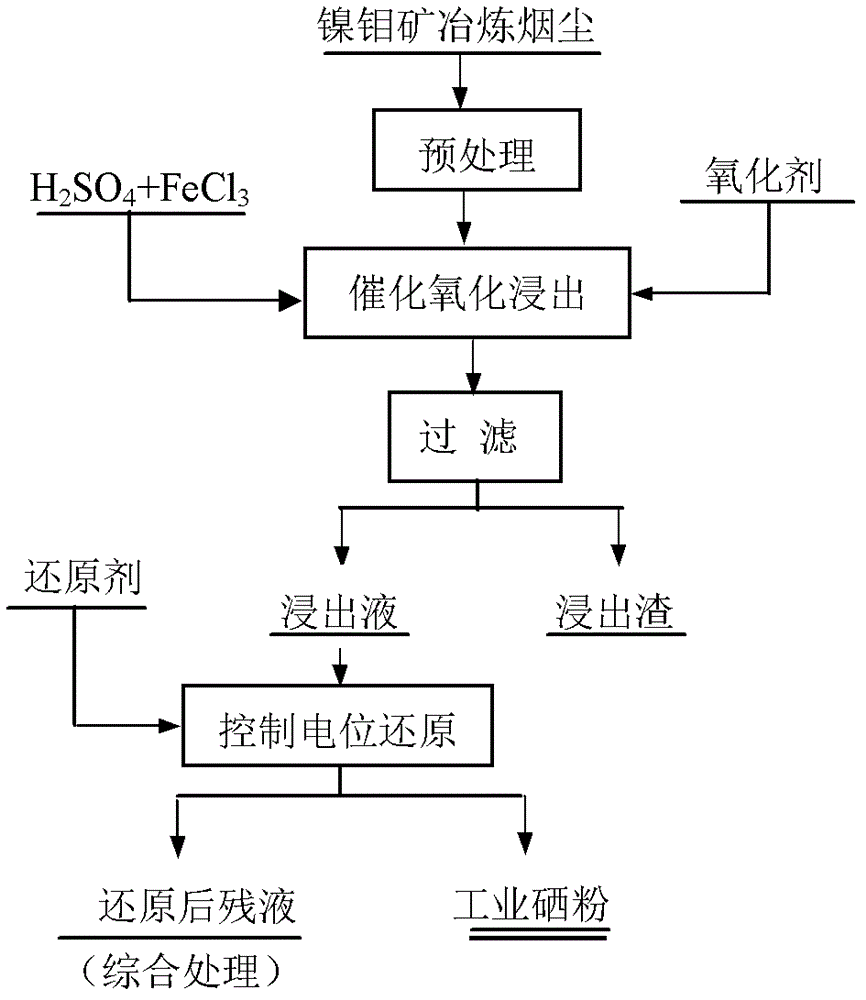

[0042] a kind of like figure 1 Shown is the technique for wet extraction of selenium from nickel-molybdenum ore smelting flue dust, comprises the following steps:

[0043] (1) Pretreatment of nickel-molybdenum ore smelting dust: firstly, the raw materials are crushed, ball milled and sieved, the oversize is returned for ball milling, the undersize (-150 mesh) is mixed evenly, and subsequent catalytic oxidation leaching is carried out;

[0044] (2) Catalytic oxidation leaching: the nickel-molybdenum ore smelting fumes pretreated in step (1) are subjected to catalytic oxidation leaching, and the catalytic oxidation leaching is carried out in a sulfuric acid leaching system, and FeCl is selected. 3 as the catalyst and hydrogen peroxide as the oxidizing agent; the specific operation process of catalytic oxidation leaching is as follows: first prepare [H + ] is 7mol / L of H 2 SO 4 Add 200ml of leaching solution into the reactor, then add 3.5g of FeCl to the leaching solution 3 a...

Embodiment 2

[0047] a kind of like figure 1 Shown is the technique for wet extraction of selenium from nickel-molybdenum ore smelting flue dust, comprises the following steps:

[0048] (1) Pretreatment of nickel-molybdenum ore smelting dust: first, crush, ball mill and sieve the raw materials, return the oversize to ball mill, and mix the undersize (-150 mesh) evenly; then, carry out subsequent catalytic oxidation leaching deal with;

[0049] (2) Catalytic oxidation leaching: the nickel-molybdenum ore smelting fumes pretreated in step (1) are subjected to catalytic oxidation leaching, and the catalytic oxidation leaching is carried out in a sulfuric acid leaching system, and FeCl is selected. 3 as the catalyst and hydrogen peroxide as the oxidizing agent; the specific operation process of catalytic oxidation leaching is as follows: first prepare [H +] is 6.5mol / L of H 2 SO 4 Add 250ml of leaching solution into the reactor, then add 4.0g of FeCl to the leaching solution 3 and 50g of ni...

Embodiment 3

[0052] a kind of like figure 1 Shown is the technique for wet extraction of selenium from nickel-molybdenum ore smelting flue dust, comprises the following steps:

[0053] (1) Pretreatment of nickel-molybdenum ore smelting dust: firstly, crush, ball mill and sieve the raw materials, return the oversize to ball mill, and mix the undersize (-180 mesh) evenly; then, carry out subsequent catalytic oxidation leaching deal with;

[0054] (2) Catalytic oxidation leaching: the nickel-molybdenum ore smelting fumes pretreated in step (1) are subjected to catalytic oxidation leaching, and the catalytic oxidation leaching is carried out in a sulfuric acid leaching system, and FeCl is selected. 3 as the catalyst and hydrogen peroxide as the oxidizing agent; the specific operation process of catalytic oxidation leaching is as follows: first prepare [H + ] is 7.5mol / L of H 2 SO 4 Leach solution 300ml, then add 14.6g of FeCl to the leach solution 3 and 50g of nickel-molybdenum ore smelti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com