Safety protection system and safety protection method for floating-roof oil tank based on active nitrogen filling

A floating roof oil tank, safety protection technology, applied in containers, packaging, transportation and packaging, etc., can solve problems such as high cost, interference, and complex environment in protected areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0093] The present invention will be further described below in conjunction with the drawings and embodiments.

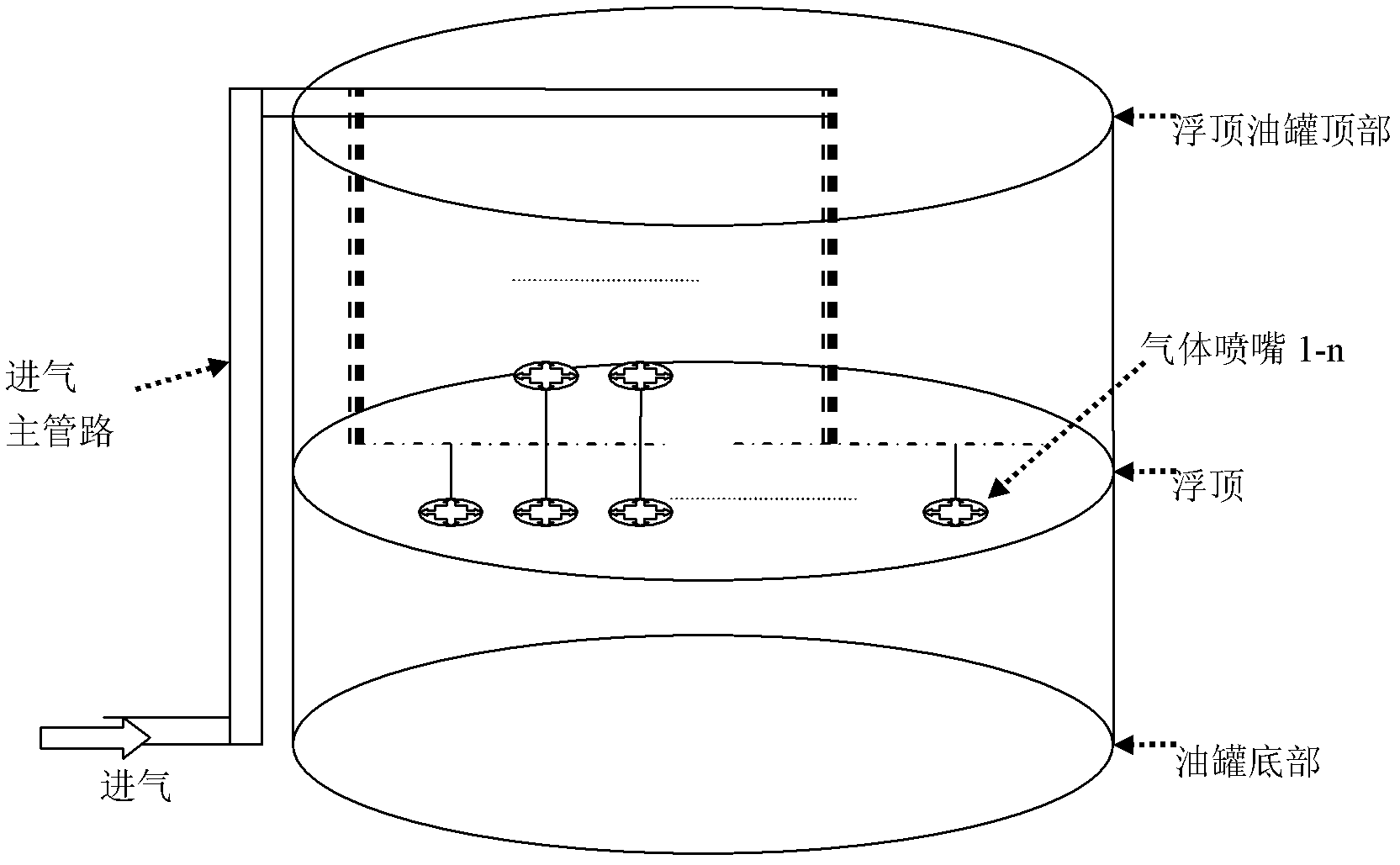

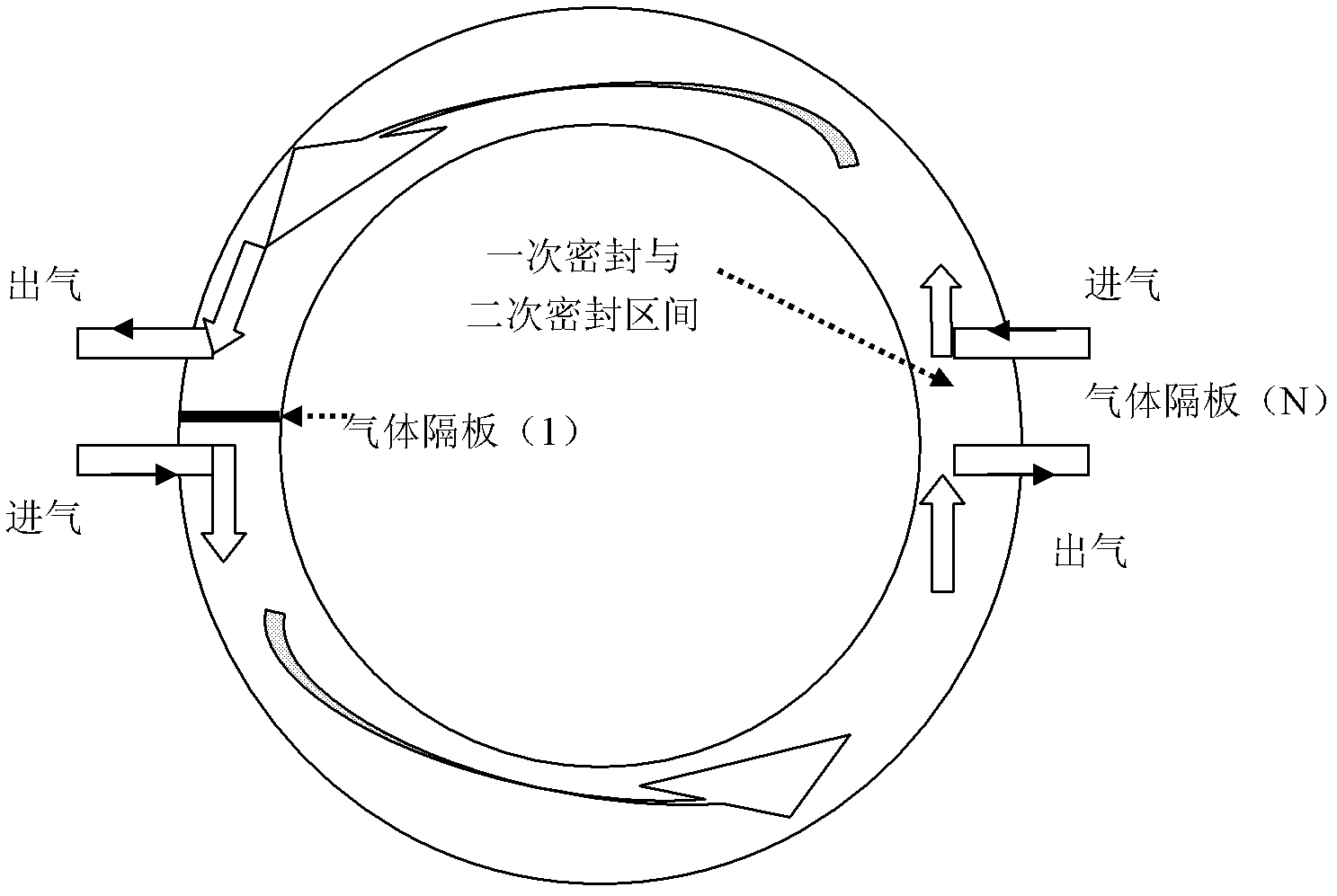

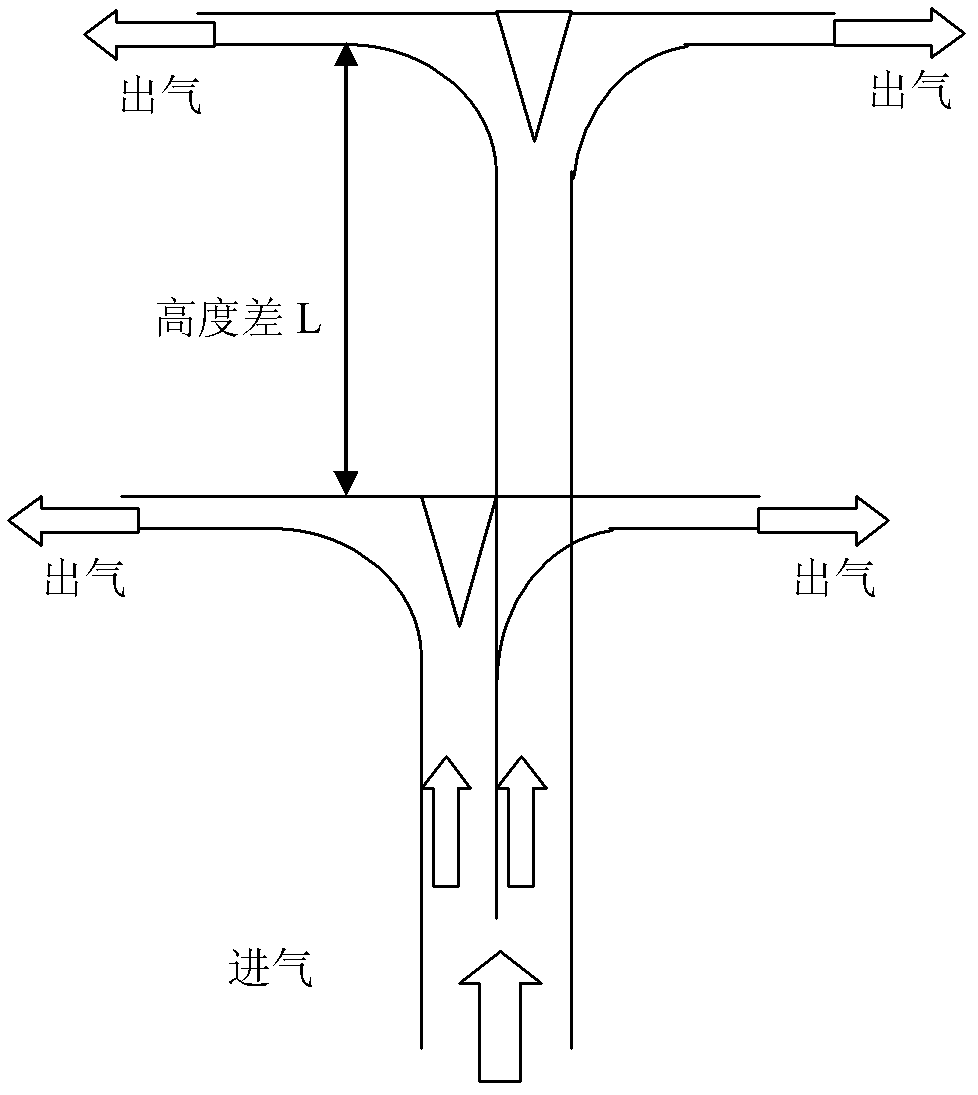

[0094] A schematic diagram of the fire protection distribution of monomer gas in floating roof tanks is as follows figure 1 Shown. The safety protection system of floating roof oil tank based on active nitrogen filling provided by the present invention, such as figure 2 As shown, at least one gas baffle is arranged in the primary and secondary sealing intervals of the floating roof oil tank, and the air inlet pipe and the air outlet pipe are matched to form a relatively independent space to facilitate gas circulation, gas collection and gas protection. The intake pipe from the backup gas source to the top of the oil tank is made of metal pipes. The backup gas source and the intake pipe are usually separated by valves. The intake pipe from the top of the oil tank to the floating roof uses a metal-encapsulated threaded hose to ensure that the nitrogen flows from After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com