Integrated tubular ceramic oxygen permeating membrane separation reactor

A tubular membrane, one-piece technology, applied in the field of ceramic oxygen-permeable membrane oxygen separation reactors, can solve problems such as being unsuitable for large-scale industrial applications, difficult to solve for sealing and component connection, and small in membrane configuration and filling area. Efficiency and practicability, strong creativity and practicability, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

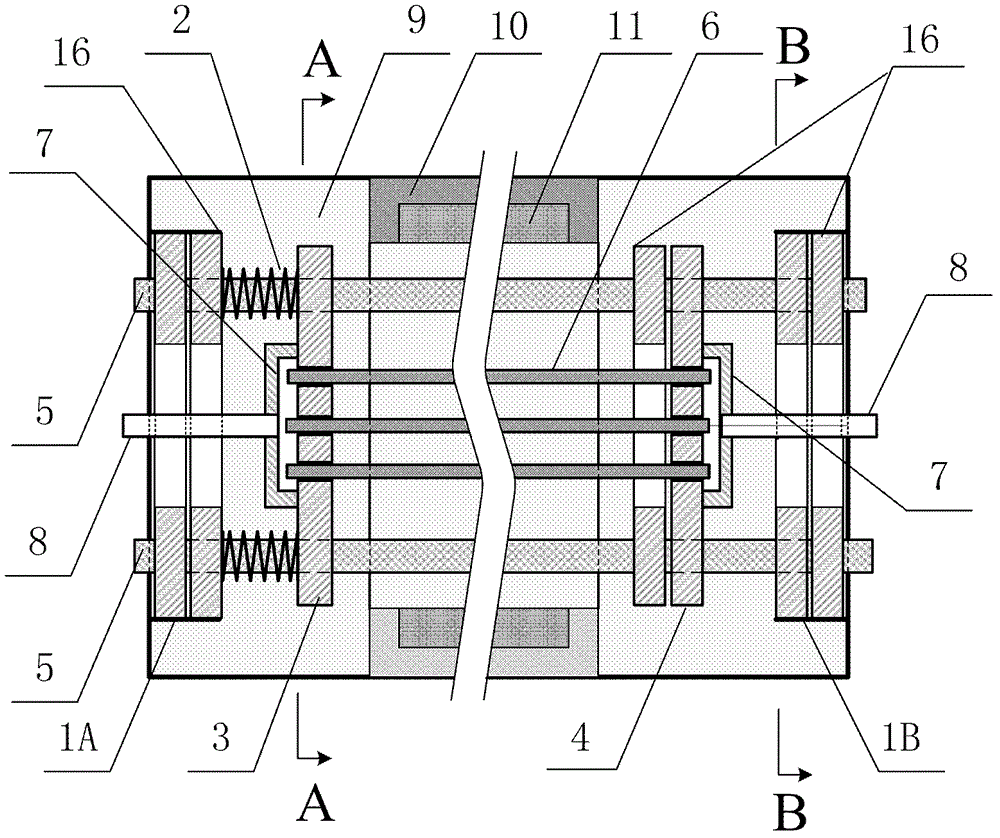

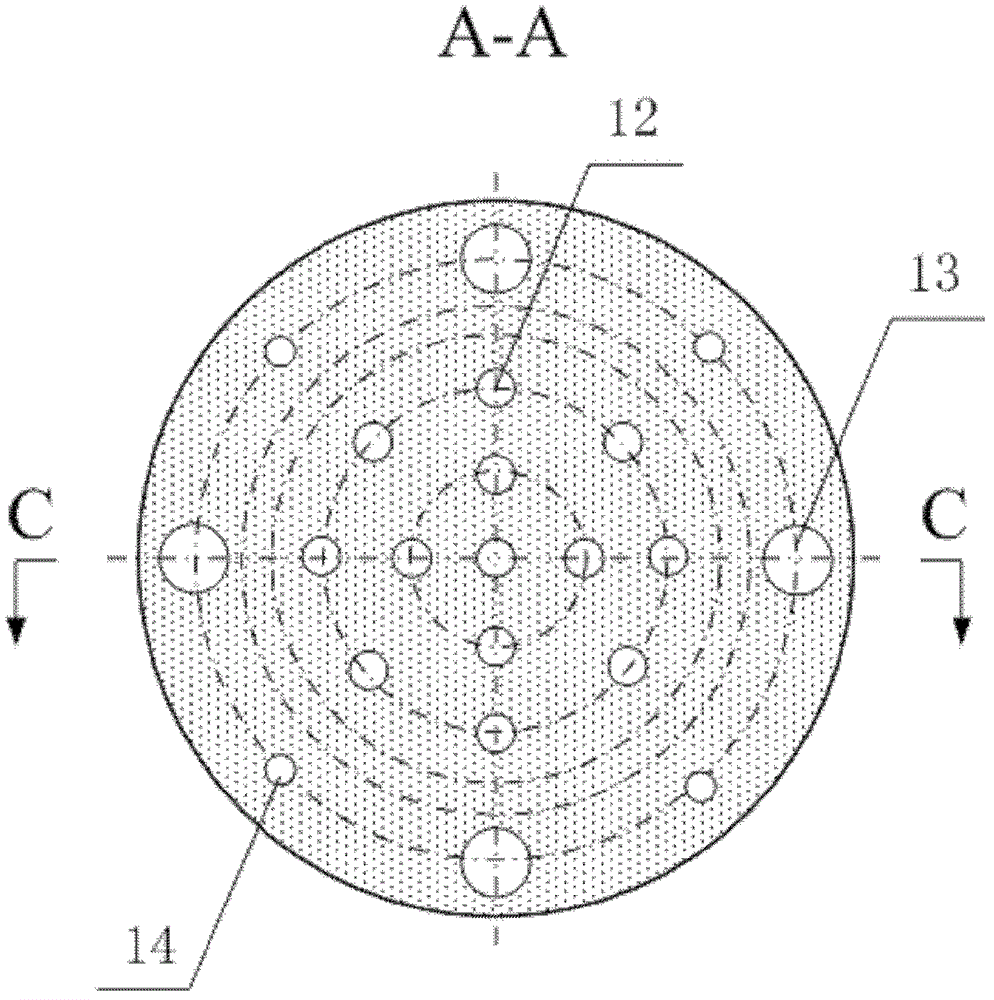

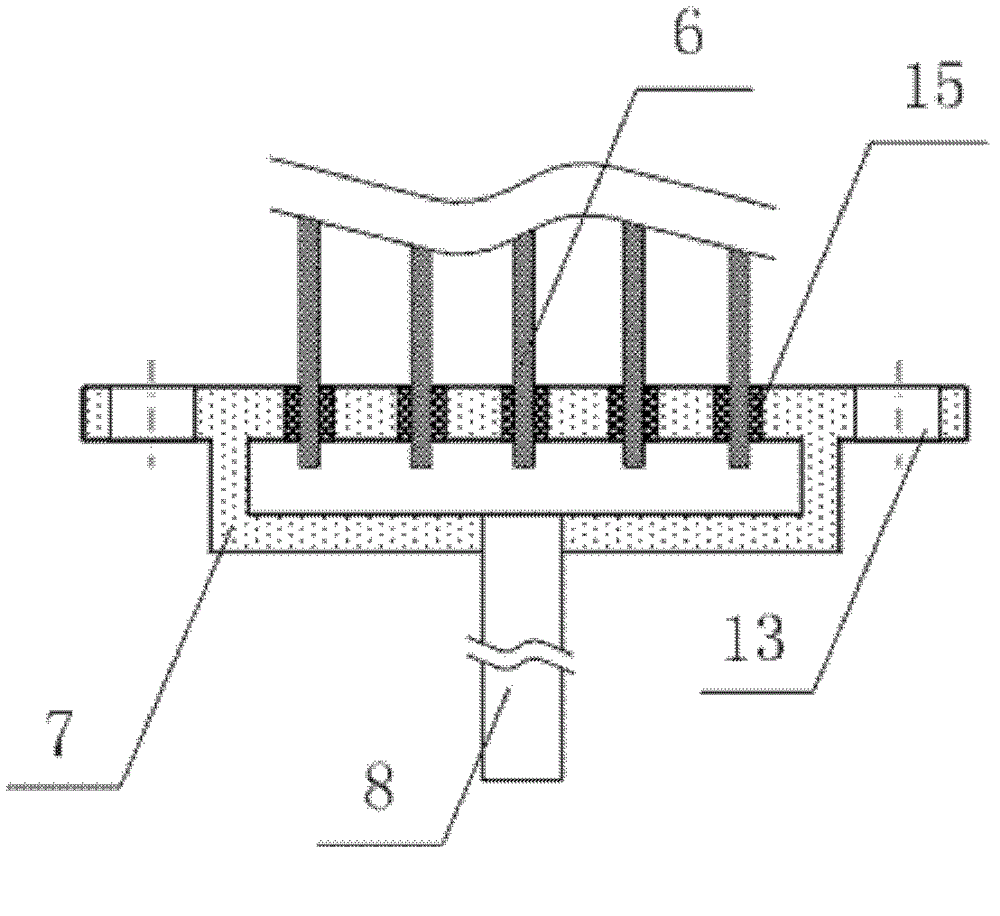

[0033] figure 1 Schematic diagram of the structure of an integrated tubular ceramic oxygen-permeable membrane separation reactor. The membrane module and the heating furnace together constitute an integrated tubular ceramic oxygen-permeable membrane separation reactor. The main part of the membrane reactor assembly is sequentially composed of the first support plate 1A, the spring 2, the moving tube plate 3, the fixed tube plate 4, and the second support plate 1B through four corundum tube guide rails 5 combined in series. The tubular ceramic membrane 6 is placed between the moving tube plate 3 and the fixed tube plate 4, and the gas inlet and outlet operations are realized through the gas collection chamber cover 7 and the connecting pipe 8. The whole membrane assembly is placed in the tubular resistance furnace 9, wherein except part of the membrane tubes and guide rods are in the heating zone of the resistance furnace (consisting of insulation cotton 10 and resistance wire...

Embodiment 2

[0039] The reactor is placed in a tubular heating furnace, and the fixed tube sheets and moving tube sheets at both ends and the sealing part are all outside the heating zone of the heating furnace. Sealant 704 silicone rubber sealant, this kind of sealant has a maximum temperature resistance of 250°C, a long-term maximum service temperature of 200°C, and excellent high temperature resistance. Use this as an indicator to determine the distance between the tube sheet (sealed part) and the heating zone of the heating furnace to ensure the sealing quality and the utilization rate of the membrane tube. Image 6 It is the axial temperature distribution curve of the non-heating zone at different center temperatures of the tube furnace. Depend on Image 6 It can be seen that with the increase of the temperature in the heating center of the tube furnace, the temperature of the furnace mouth also rises accordingly, while the axial temperature outside the furnace decreases rapidly with...

Embodiment 3

[0041] Different from the normal temperature tubular membrane equipment, the device in the present invention is in a high temperature environment (>500°C), and some devices are also in a normal temperature environment. Components in a high-temperature environment will inevitably cause large expansion or contraction during the heating and cooling process, and there will be a large difference in thermal expansion performance between components and components in a normal temperature environment. If the problem caused by material expansion cannot be effectively solved Poor stress will greatly endanger the structural stability of the membrane module, and even cause the rupture of the membrane tube, the leakage of flammable gas and the danger of explosion. In this embodiment, the thermal expansion performance of each component in a high temperature environment is tested, Figure 7 It is the thermal expansion curve of different rail materials and membrane tube materials, assuming tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com