Electrically conductive paste, electrically conductive film, touch panel, and process for production of electrically conductive thin film

A conductive paste, non-crystalline technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, conductive coatings, etc., can solve coating film leakage, uneven distribution of coating film, conductivity Or the impact of surface hardness and other issues, to achieve high reliability, improve adhesion, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0099] Examples and comparative examples are shown below to describe the present invention more specifically. In addition, this invention is not limited to the following embodiment. In addition, unless otherwise specified, "parts" in examples means "parts by mass", and the solid content concentration means the concentration of non-volatile matter after the solvent is completely volatilized.

[0100] Physical property evaluation (1. Number average molecular weight, 2. Glass transition temperature (Tg), 3. Acid value, and 4. Resin composition) of polyester resin (P) and polyurethane resin (U) produced in the production examples described later ) is measured as follows.

[0101] In addition, 10. storage stability of the conductive paste prepared using the polyester resin (P) and polyurethane resin (U) prepared in the production example, and the physical property evaluation of the test piece formed using the conductive paste (5. Adhesiveness, 6. Resistivity, 7. Pencil hardness, ...

manufacture example

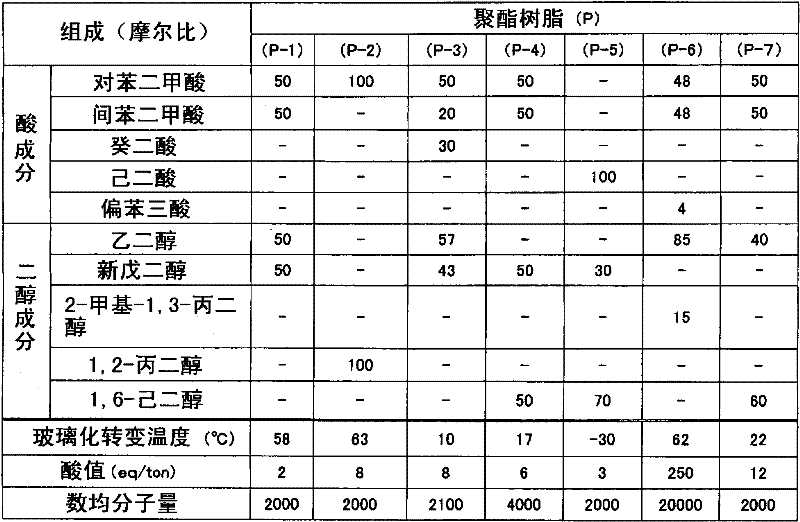

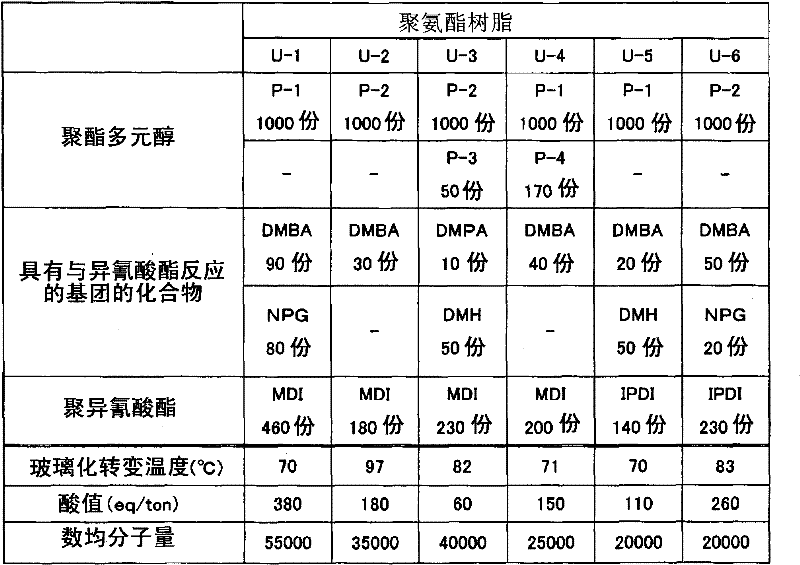

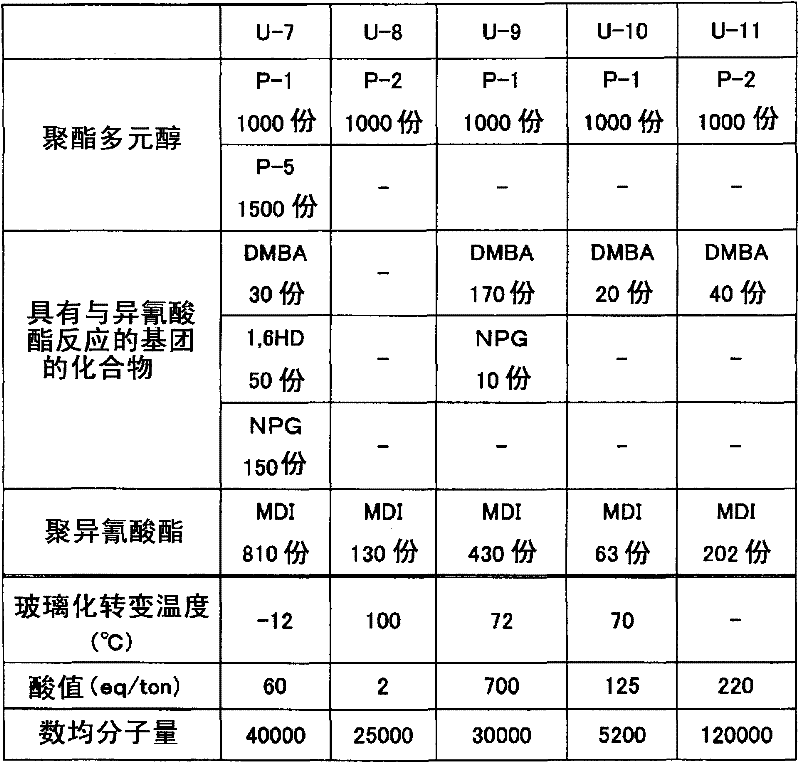

[0128] Synthesis of Polyester Polyol (P)

[0130] 700 parts of dimethyl terephthalate, 700 parts of dimethyl isophthalate, 671 parts of ethylene glycol, 526 parts of neopentyl glycol, tetratitanate 0.48 parts of butyl esters were transesterified at 180° C. for 3 hours. Next, the pressure was gradually reduced to below 1 mmHg, and polymerization was carried out at 240° C. for 1.5 hours. The composition of the obtained copolyester P-1 is terephthalic acid / isophthalic acid / / ethylene glycol / neopentyl glycol=50 / 50 / / 50 / 50 (molar ratio), number average molecular weight 2,000, acid Value 2eq / ton, Tg=58°C. The results are shown in Table 1.

[0131] Polyester polyol (P-2)~(P-5) and (P-7)

[0132] In the polyester polyol (P-1), the acid component and the diol component shown in Table 1 were used, and the monomers were replaced to the molar ratios in Table 1. In addition, by mixing with the polyester polyol (P- 1) Synthesis was carried out in the same...

Embodiment 1

[0165] 2,858 parts of polyurethane resin solution (U-1) with a solid content concentration of 35% by mass (1,000 parts in terms of solid content), 6,540 parts of flaky silver powder SF70A manufactured by Ferro Japan Co., Ltd., and carbon black manufactured by Lion Co., Ltd. 76 parts of ECP600JD, 76 parts of graphite BF manufactured by Chuetsu Graphite Industry Co., Ltd., 58 parts of MK Conk manufactured by Kyoeisha Chemical Co., Ltd. for the leveling agent, and 215516 parts of Disperbyk manufactured by Vitsuku Chemical Japan Co., Ltd. for the dispersant , The solvent is mixed with 640 parts of diethylene glycol ethyl ether acetate (ECA) and 210 parts of carbitol butyl ether acetate (BCA), and dispersed 3 times by chilled rolling three-roll mixer. Table 4 shows the amount of each component in all solutions. The obtained silver paste annealed PET film was used as a substrate, and after printing according to the method specified in 5. Adhesion test, it was dried at 120° C. for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com