Ultra-wideband microstrip filter

A microstrip filter and ultra-wideband technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of not designing ultra-wideband, and achieve low return loss and good harmonic suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

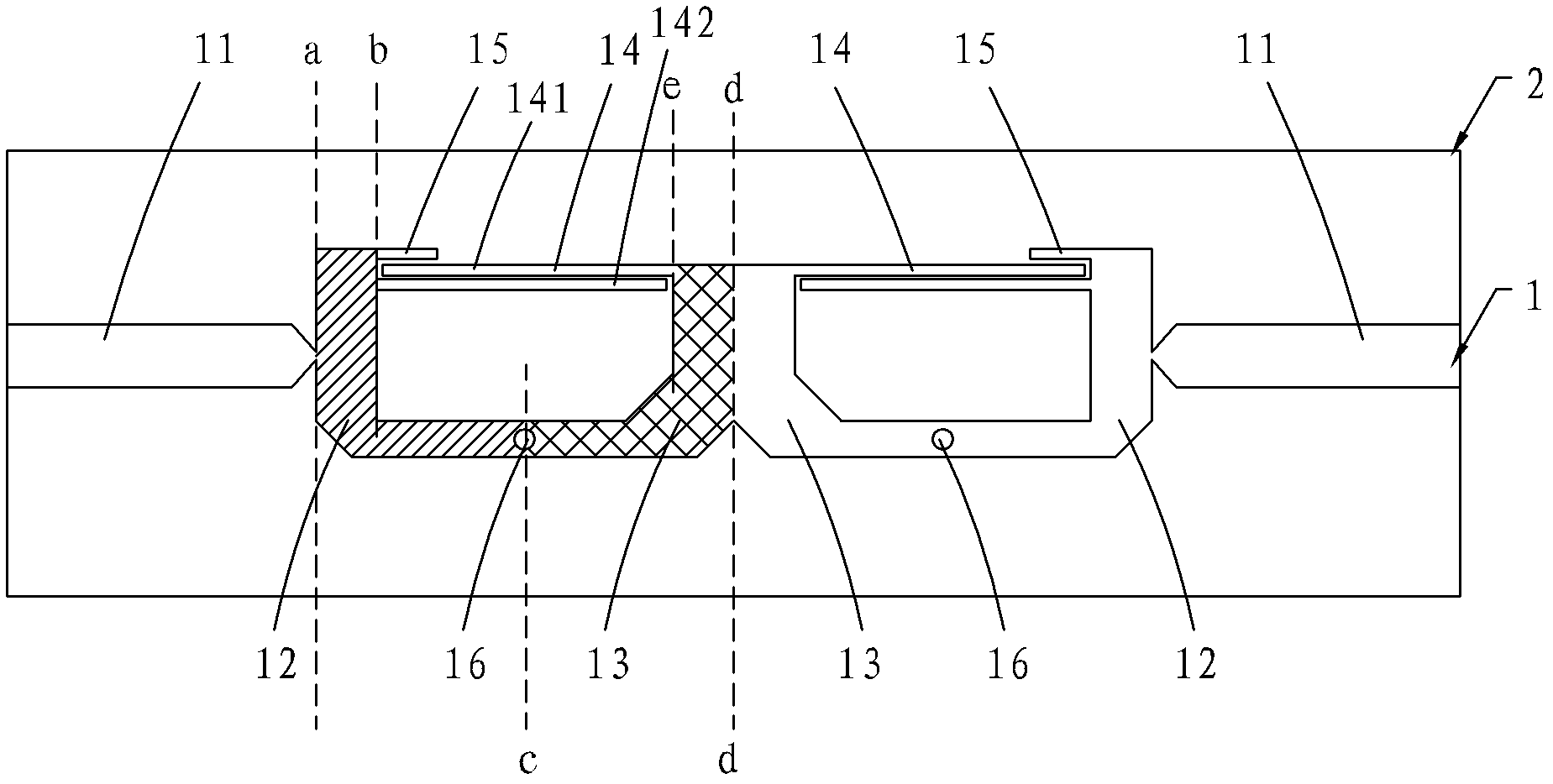

[0021] Such as figure 2 with image 3 As shown, an ultra-wideband microstrip filter includes a first metal layer 1, a dielectric layer 2, and a second metal layer 3 stacked in sequence from top to bottom, and the metal pattern of the first metal layer 1 includes left and right mirror symmetry The left metal pattern and the right metal pattern are characterized in that, the left metal pattern or the right metal pattern respectively include sequentially connected input and output ports 11, a first step impedance short-circuit stub 12, a second step The impedance short-circuit stub 13 and the cross-toe coupling line section 14, the first step impedance short-circuit stub 12, the second step impedance short-circuit stub 13 and the cross-toe coupling line section 14 form a ring structure as a resonant unit of the filter, The cross-toe coupled lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com