Variable valve timing distribution regulating device and method for improving mechanical property of variable valve timing distribution regulating device

A valve timing and adjustment device technology, applied in valve devices, mechanical equipment, engine components, etc., can solve the problems of accelerated adjustment device damage time, shortened life, polluted working oil, etc., to improve surface hardness and wear resistance. , The effect of improving heat resistance and corrosion resistance, and prolonging working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

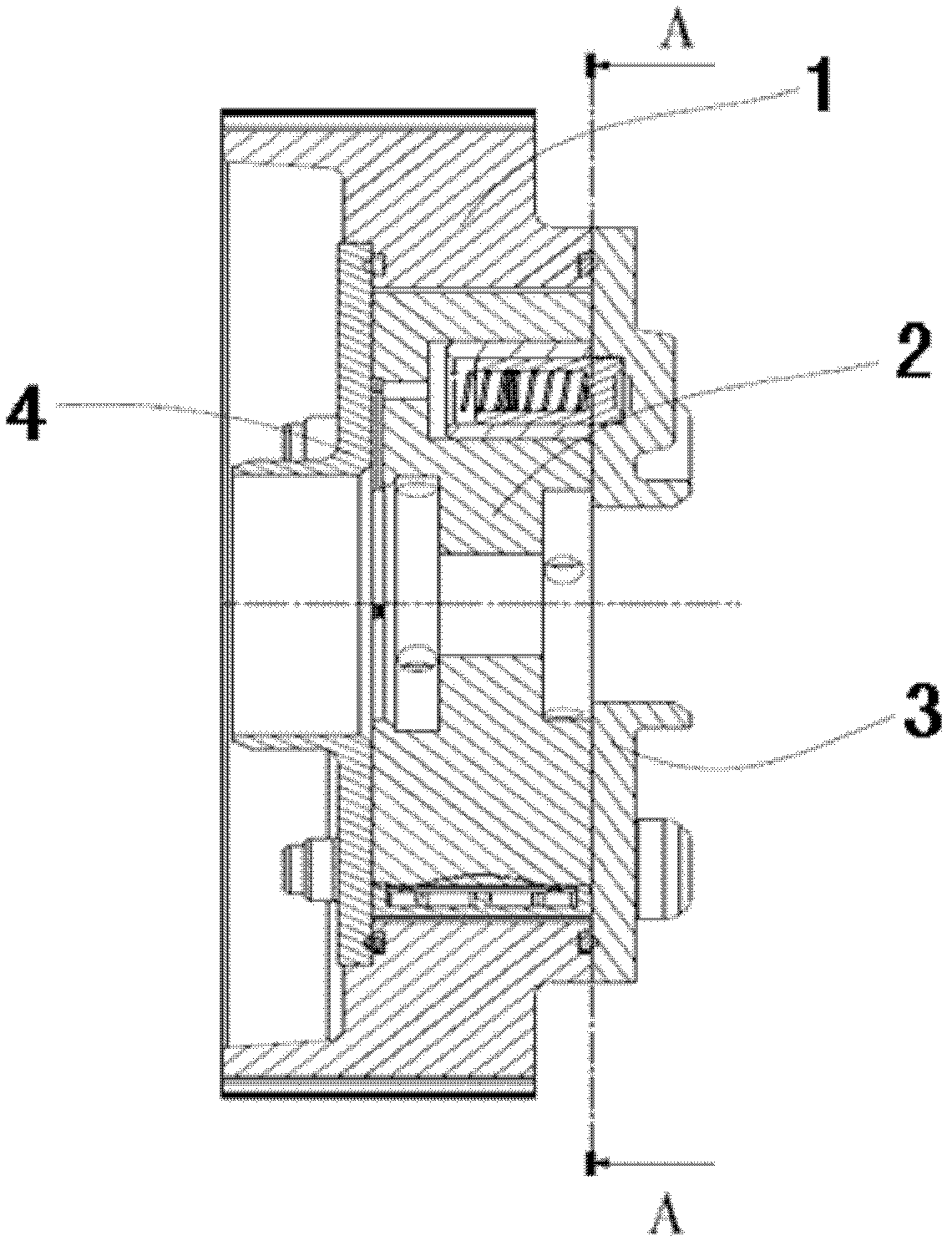

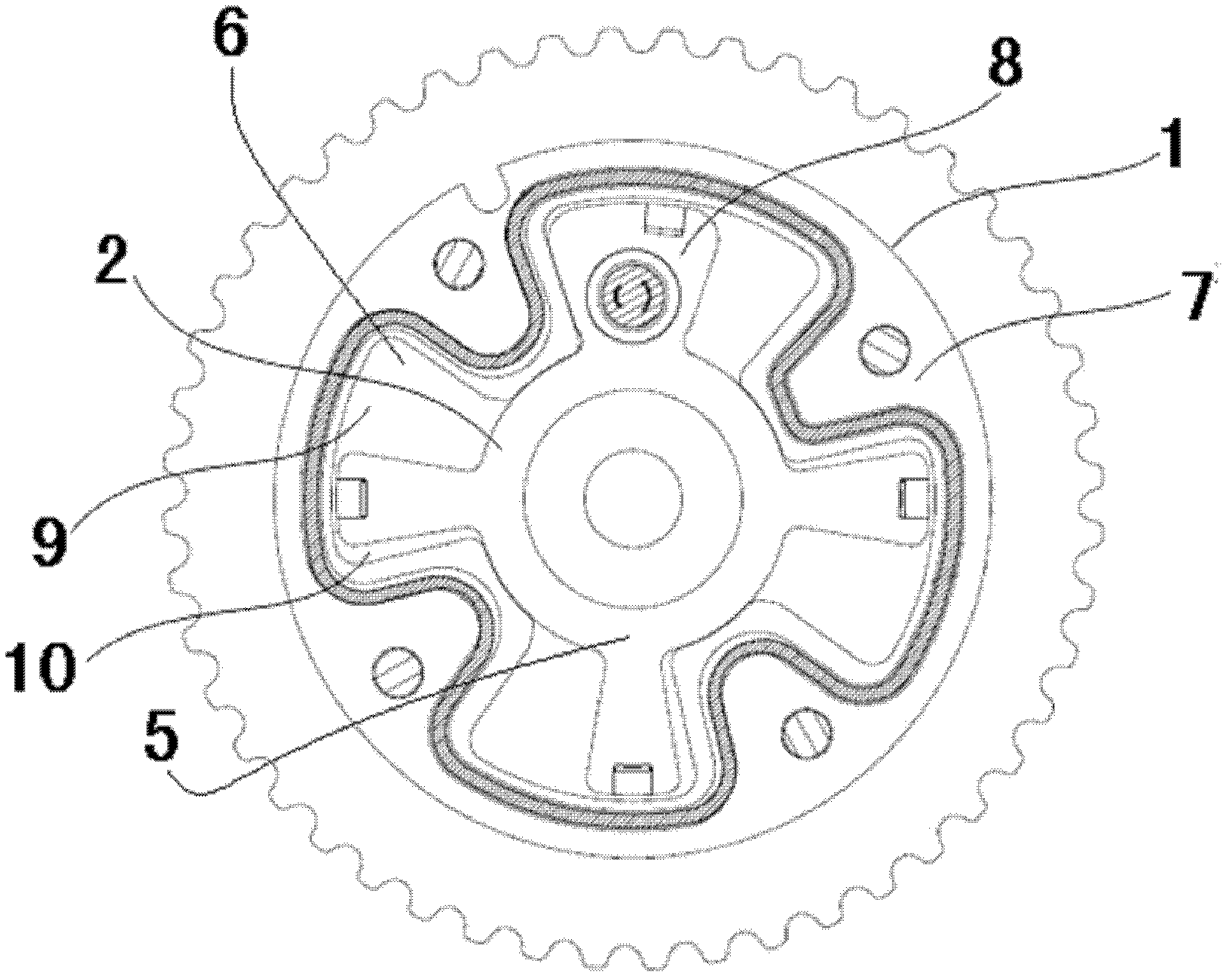

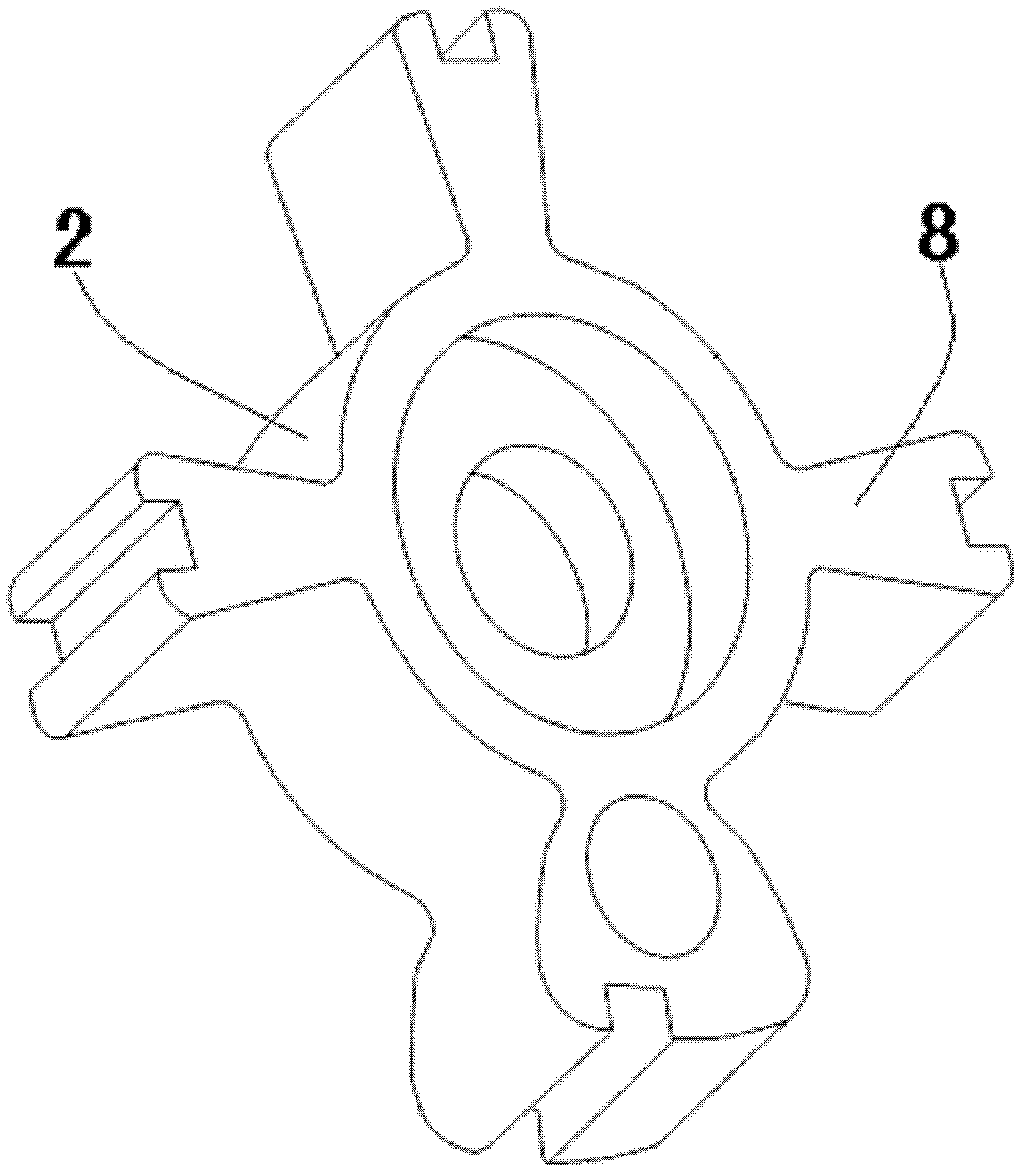

[0029] In the following, referring to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape and structure of each component involved, the mutual position and connection relationship between each part, the function and working principle of each part, etc. will be further described. Details of:

[0030] as attached figure 1 -Attached Figure 4 As shown, the present invention is a variable valve timing valve adjustment device. The variable valve official valve adjustment device includes a stator 1, a rotor 2, a front cover 3, and a rear cover 4. The The surface of the components of the variable valve timing valve adjustment device is provided with an oxide coating film 5 formed by electrochemical surface treatment.

[0031] The surfaces of the stator 1 and the rotor 2 are respectively provided with an oxide coating film 5 formed by electrochemical surface treatment, and the stator 1 and the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com