Yeast engineering bacterial strain capable of producing glutathione and application thereof to production of glutathione

A technology of glutathione and yeast engineering, applied in the direction of fermentation, fungi, microorganisms, etc., to achieve the effects of promoting cell growth and product synthesis, increasing yield and yield, and improving utilization capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

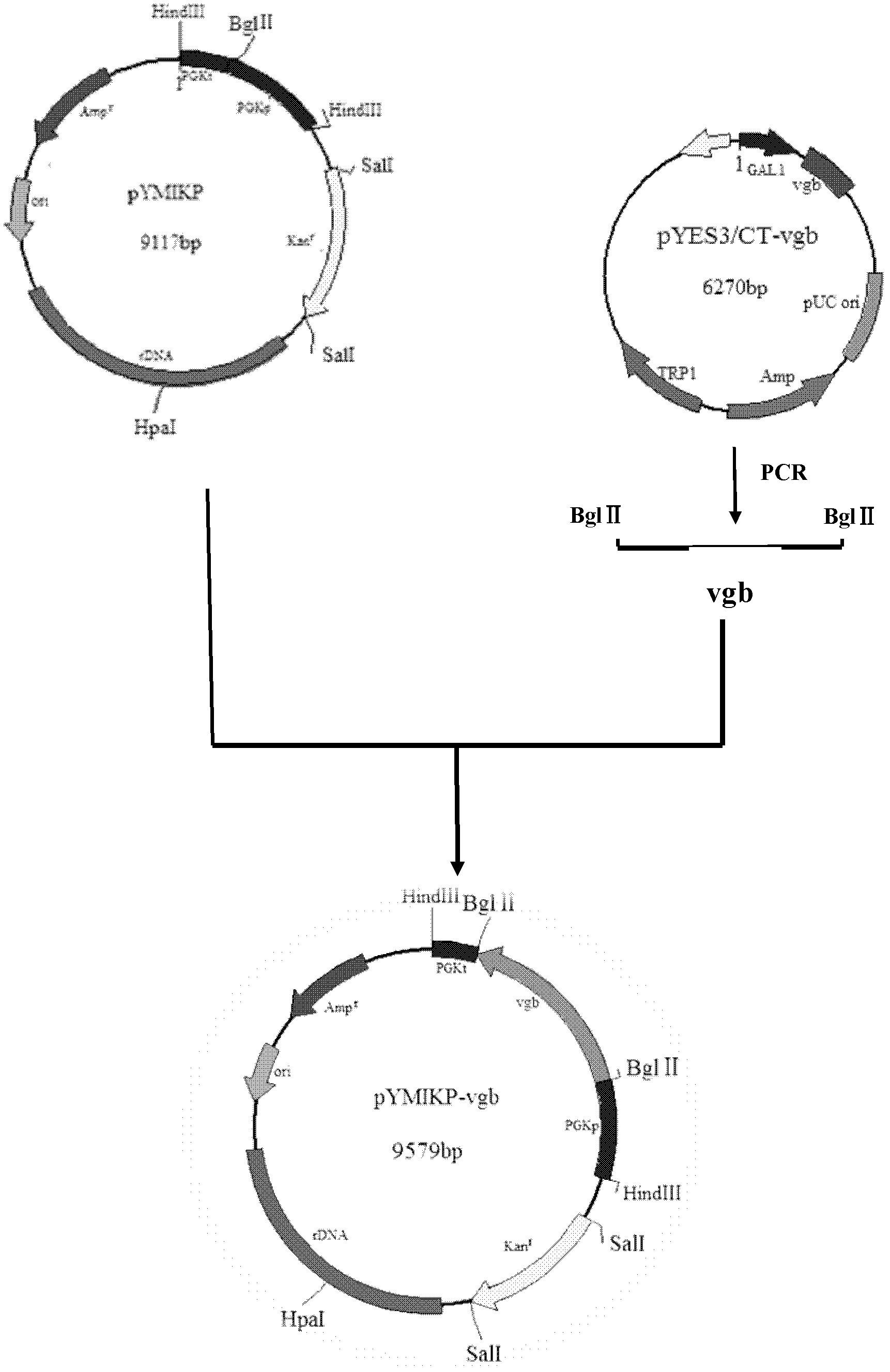

[0039] Example 1: Construction of Saccharomyces cerevisiae integration vector expressing VHb

[0040] 1. Acquisition of the vgb sequence of the hemoglobin gene of Vitreum hyalineus. Use the vector pYES3 / CT-vgb as a template to amplify the target gene vgb, and the primers are:

[0041] Upstream primer: 5′GGCGCAGATCTATGTTAGACCAGCAAAC3′

[0042] Downstream primer: 5'GGCAGATCTTTATTCAACCGCTTGAGC3'

[0043] The 5' of the primers are all introduced into the Bgl II restriction site. Amplification conditions are: ①95°C, 5min; ②94°C, 30s; ③56°C, 30s; ④72°C, 1min; ⑤cycle 30-35 times; ⑥72°C, 10min.

[0044] 2. Digest the vgb fragment and the vector pYMIKP with Bgl II, and then connect with T4 DNA ligase.

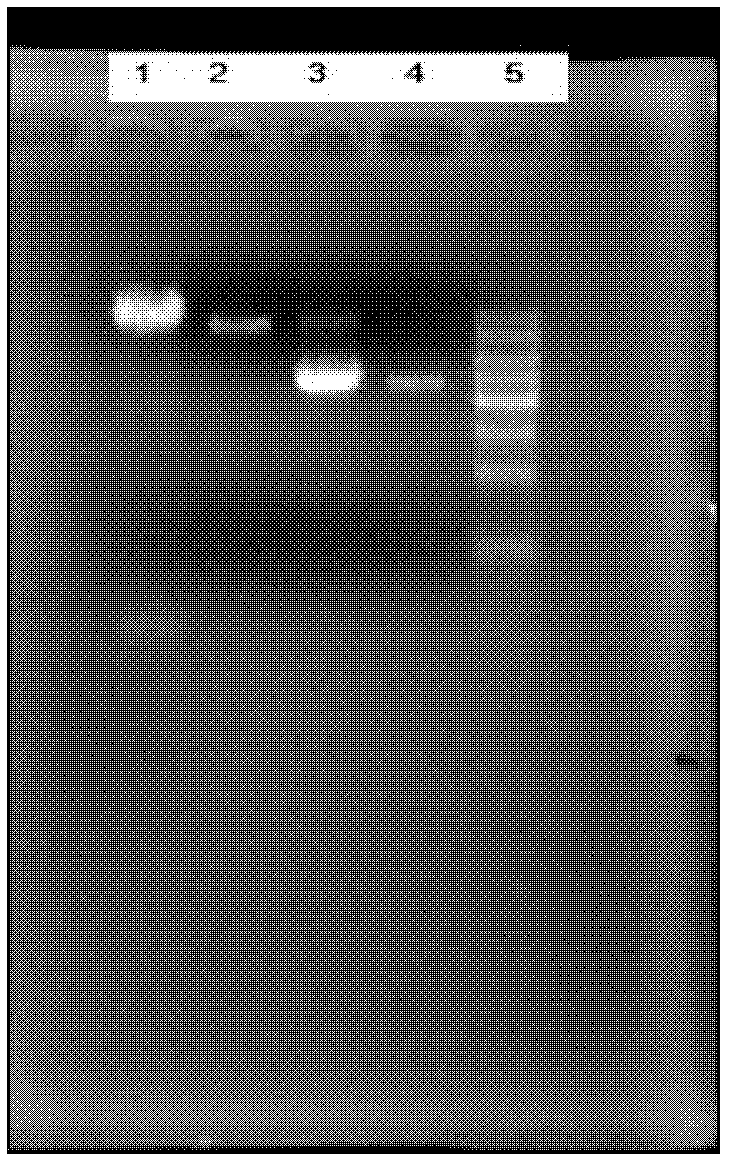

[0045] 3. The ligation product was transformed into Escherichia coli TOP10 competent cells, positive clones were screened, and the recombinant plasmid pYM-vgb was identified by PCR and DNA sequencing analysis, and finally the recombinant expression plasmid pYM-vgb was obtained (for ...

Embodiment 2

[0046] Embodiment 2: Contain the construction of VHb genetically engineered bacteria

[0047] The correctly sequenced recombinant plasmid pYM-vgb in Example 1 was digested and linearized with restriction endonuclease Kpn I, and the digested product was purified by ethanol precipitation, recovered and used for electrotransformation. The specific method is as follows:

[0048] (1) Inoculate a single colony of the yeast strain used for transformation into 5 ml of YPD medium, and culture overnight at 30°C and a shaker speed of 220r / min until saturation;

[0049] (2) Inoculate an appropriate amount of overnight culture solution in 50ml of YPD medium until the OD600 is about 1.3-1.5; harvest the cultured cells by centrifugation at 4°C and 3000r / min, and resuspend the cells in 100ml of sterile water;

[0050] (3) Add an appropriate amount of 1mol / L dithiothreitol (DTT, used to loosen the cell wall) solution, rotate and shake at the same time, and shake gently at 30°C for 15 minutes;...

Embodiment 3

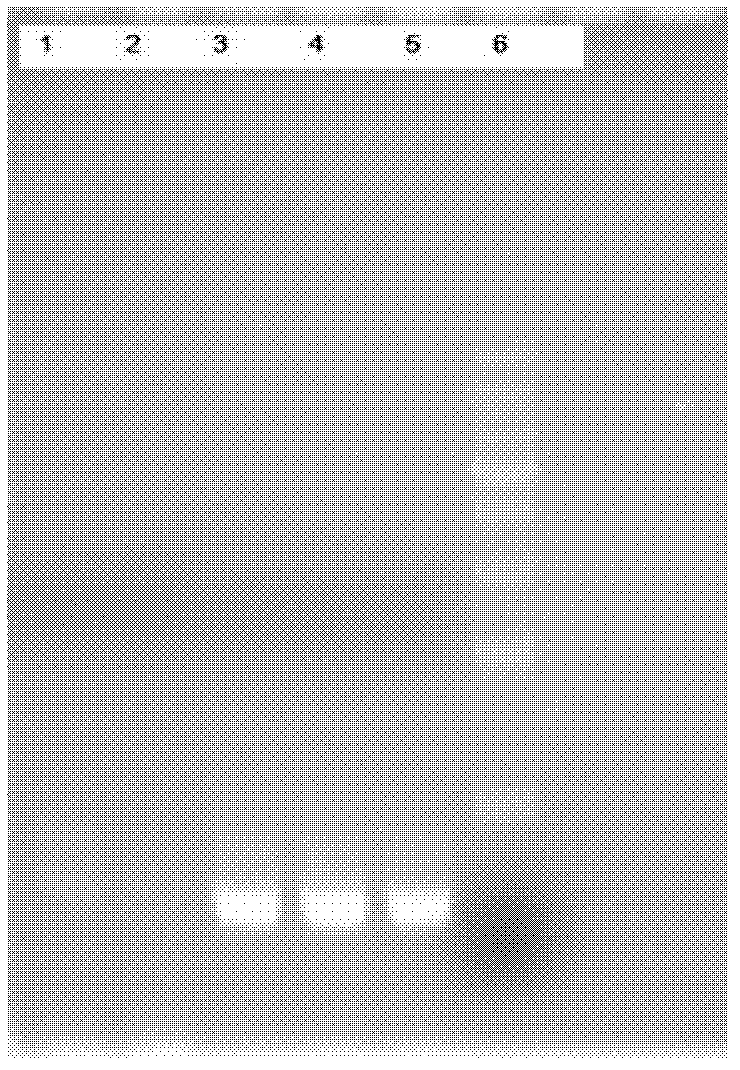

[0063] Embodiment 3: Fermentation experiment of genetically engineered bacteria

[0064] The original strain and the recombinant strain obtained in Example 2 were respectively inoculated into 250 ml Erlenmeyer flasks containing 50 ml of YPD liquid medium, cultured overnight at 30° C., and the shaker speed was 220 r / min. The cultivated seed medium was inoculated into a 250 ml Erlenmeyer flask containing 100 ml of fermentation medium with an inoculum amount of 2%, and cultivated at 30° C. for 28 hours, and the shaker speed was 220 r / min. After the fermentation, the content of glutathione was determined by the Alloxan method (Shanghai Medical Laboratory. Clinical Biochemical Test [M]. Shanghai Science and Technology Publishing, 1979, 86-88.). The fermentation results showed that: the liquid volume of 100ml was not enough for the 250ml Erlenmeyer flask, which could not meet the oxygen demand of the yeast during the growth process. The output of the original strain in 100ml fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com