Protection finish paint for wind power blade and preparation method of protection finish paint

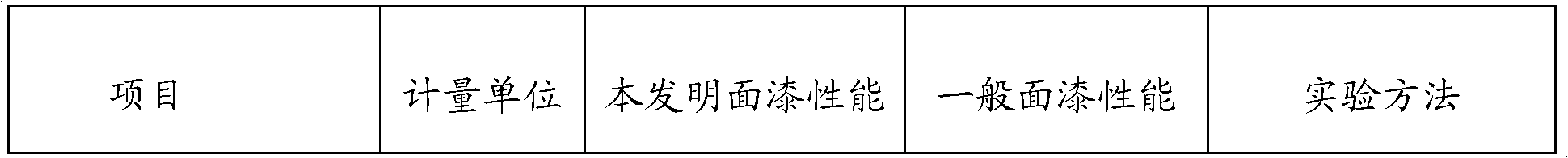

A technology for wind turbine blades and protective surfaces, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor use of wind turbine blade protective finishes, wear resistance, and thick film coating, which affect wind power Problems such as the efficiency of blade coating construction, to achieve high weather resistance, increase the construction thickness, and improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of component A: 1g of polyamine block copolymer solution-based wetting and dispersing agent, 0.4g of silane-based adhesion promoter, 1.5g of anti-aging agent (0.8g of salicylate-based UV absorber, metal complex Species quencher 0.3g, hindered amine free radical scavenger 0.4g), 0.2g methyl alkylpolysiloxane defoamer, 0.3g modified silicone resin defoamer, 1.0g composite contact Modifier (fumed silica 0.4g, modified urea thixotropic agent 0.6g), 1.5g wear additive (fluorinated silane polymer 0.8g, polytetrafluoroethylene micro-wax powder 0.7g) was added to 45g as Add 18g of solvent (15g of butyl acetate, 3.0g of propylene glycol methyl ether acetate) into the modified hydroxyacrylic resin of the lacquer base (this resin is modified by linear polyester) and stir for 5-10 minutes before adding Stir 26g of titanium dioxide at high speed for 35-45 minutes, and finally add 5.1g of fumed silica-based matting agent and stir for 15-20 minutes.

[0034] Preparation o...

Embodiment 2

[0037] Preparation of component A: 1.0g of polyamine block copolymer solution-based wetting and dispersing agent, 0.5g of silane-based adhesion promoter, 1.7g of anti-aging agent (1.0g of salicylate-based UV absorber, metal complex Compound quencher 0.3g, hindered amine free radical scavenger 0.4g), 0.2g methyl alkyl polysiloxane defoamer, 0.3g modified silicone resin defoamer, 0.8g composite Thixotropic agent (fumed silica 0.4g, modified urea thixotropic agent 0.4g), 2.0g wear additive (fluorinated silane polymer 1.0g, polytetrafluoroethylene micro-wax powder 1.0g) was added to 47g Add 15g of solvent (12g of butyl acetate, 3.0g of propylene glycol methyl ether acetate) into the modified hydroxyacrylic resin, stir for 5-10 minutes, add 26g of titanium dioxide and stir at high speed for 35-45 minutes, and finally add 5.5g of meteorological silica The matting powder can be stirred for 15-20 minutes.

[0038] Preparation of component B: Dissolve 50g of HDI trimer and 35g of IPDI...

Embodiment 3

[0041] Preparation of component A: 1.0g of polyamine block copolymer solution-based wetting and dispersing agent, 0.5g of silane-based adhesion promoter, 1.6g of anti-aging agent (0.8g of salicylate-based UV absorber, metal complex Compound quencher 0.4g, hindered amine free radical scavenger 0.4g), 0.2g methyl alkylpolysiloxane defoamer, 0.3g modified silicone resin defoamer, 0.7g composite Thixotropic agent (0.3g meteorological silica, 0.4g modified urea thixotropic agent), 2.0g wear-resistant additive (1.0g fluorinated silane polymer, 1.0g polytetrafluoroethylene micro-wax powder) were added to 49g In the modified hydroxyacrylic resin, add 12g solvent (9.0g butyl acetate, 3.0g propylene glycol methyl ether acetate), stir for 5-10 minutes, add 27g titanium dioxide and stir at high speed for 35-45 minutes, and finally add 5.7g Meteor II Silica matting powder can be stirred for 15-20 minutes.

[0042]Preparation of component B: Dissolve 60g of HDI trimer and 30g of IPDI in 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com