Low odor, anti-static electricity, red phosphorus flame retardant thermoplastic composition and preparation method thereof

A thermoplastic composition and antistatic technology, applied in the field of modified polyamide, can solve problems such as deterioration of working environment and endangering the health of production personnel, achieve good flame retardancy and mechanical strength, reduce phosphorus precipitation and excessive odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

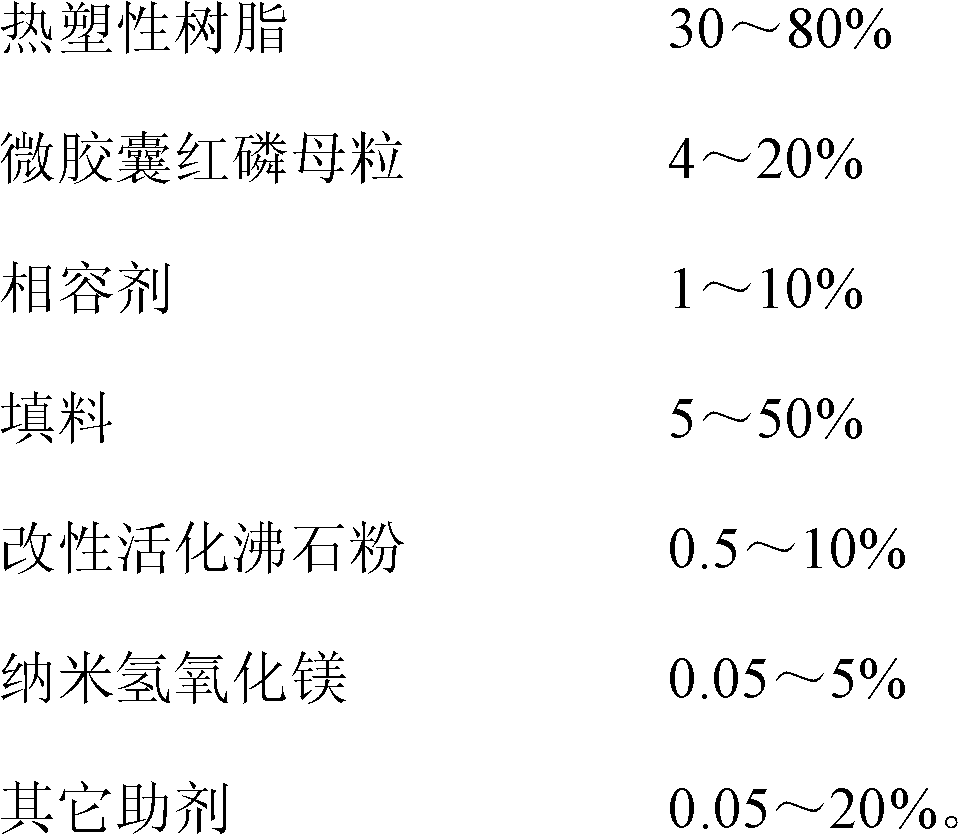

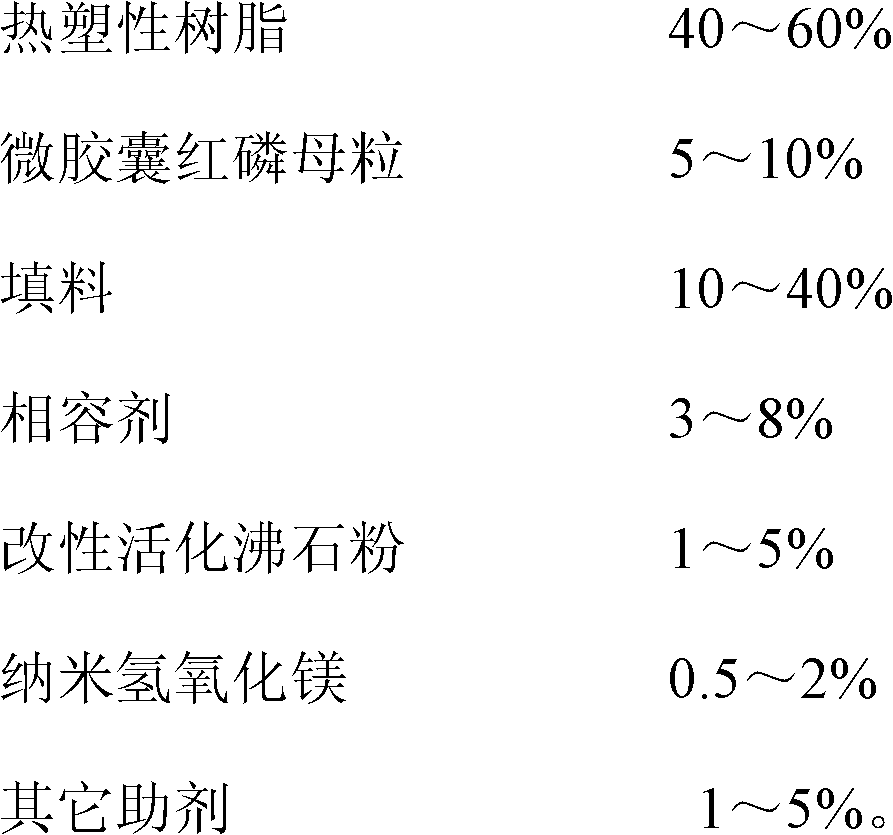

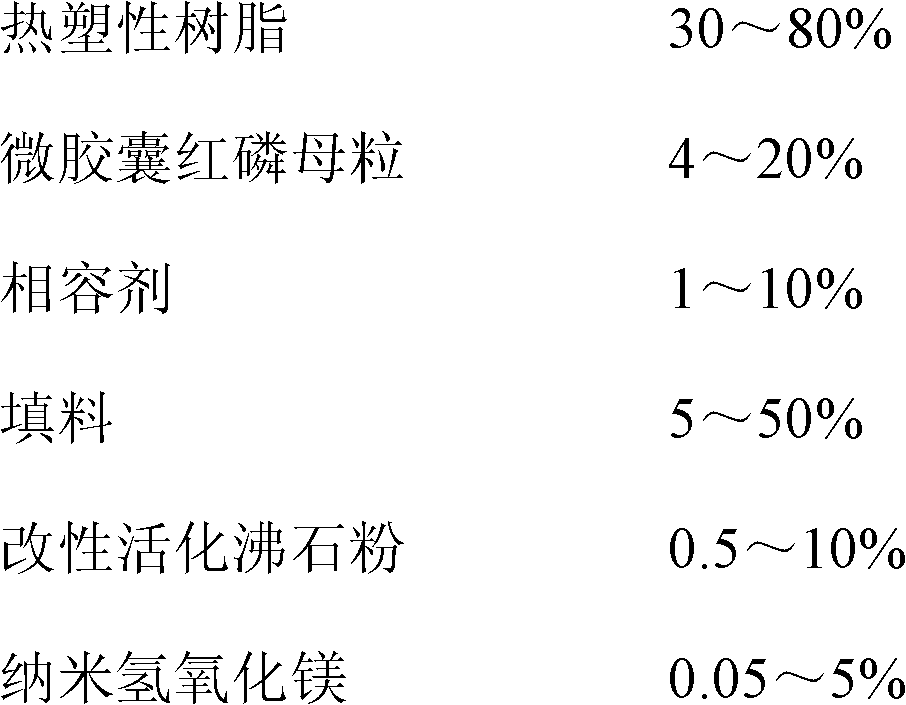

Method used

Image

Examples

Embodiment Construction

[0024] Preparation and testing methods: Extrude each component in a twin-screw extruder (twin-screw diameter 30mm, aspect ratio 44) at a temperature of 220-300°C, discharge as strands and cool to a temperature capable of granulation Granulation, after the pellets are dried in an oven at 110°C for 4-5 hours, the obtained pellets are processed into test specimens at a temperature of 220-300°C, including ISO standard tensile, bending, thermal deformation, impact, etc. module.

[0025] The odor test is carried out according to the Volkswagen interior odor test method PV3900; the test judgment standard is divided into 1 to 6 levels, and there will also be situations between the two evaluation levels.

[0026] Rating 1 Odorless

[0027] Rating 2 Smells, but not disturbing

[0028] Score 3 Odor is noticeable but not disturbing

[0029] Rating 4 Disturbing smell

[0030] Score 5 has a strong disturbing smell

[0031] Rating 6 has an unbearable smell

[0032] Bacteriostasis is ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com