Positive temperature coefficient material, preparation method thereof and thermistor containing positive temperature coefficient material

A positive temperature coefficient, thermistor technology, applied in the direction of resistors with positive temperature coefficient, etc., can solve the problems of low PTC strength, the thermistor cannot be used normally, and poor aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a method for preparing a positive temperature coefficient material, comprising the following steps:

[0020] 1) Mix additives, nucleating agents, and polymers in an extruder and cut them into mixture I with a particle diameter of 4 mm;

[0021] 2) Fully mix the titanate-modified conductive filler and titanate-modified flame retardant in a high mixer to obtain mixture II;

[0022] 3) mixing mixture I, mixture II and lubricant in an internal mixer to obtain a positive temperature coefficient thermistor material;

[0023] Wherein, based on the total weight of the mixture I, II and the lubricant, based on the total weight of the mixture, the content of the additive is 0.5-10 wt%, and the content of the polymer is 5-15 wt%, The content of the nucleating agent is 0.5-10wt%, the content of the lubricant is 0.5-3wt%, the content of the titanate-modified conductive filler is 80-90wt%, the content of the titanate-modified flame retardant is 1- 6wt%; the a...

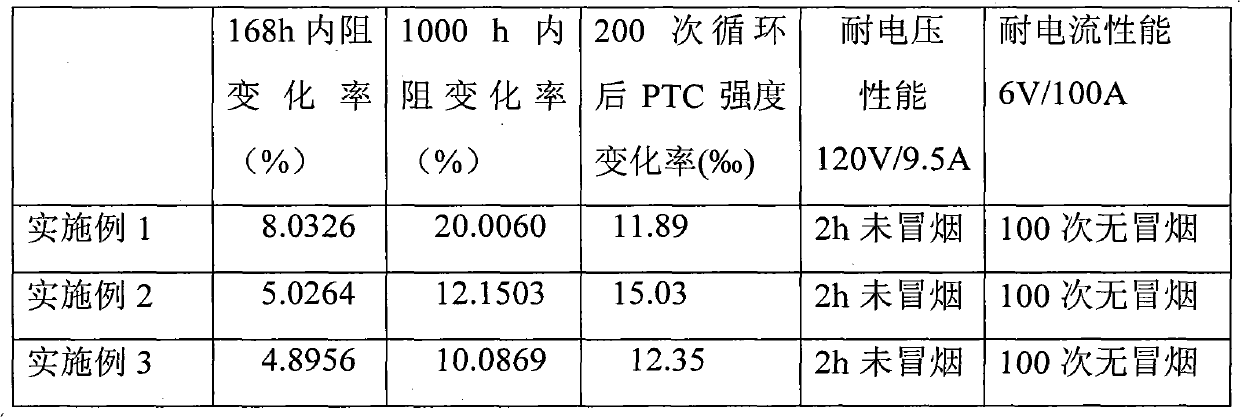

Embodiment 1

[0042] This embodiment is used to illustrate the preparation of the positive temperature coefficient material and thermistor of the present invention.

[0043] By mixing 2% ethylene-octene copolymer, 2% EPDM, and 10% high-density polyethylene resin that account for the positive temperature coefficient material to obtain a mixture, the mixture obtained above is sent into a twin-screw compounding extruder ( In SJSH-30 type, Nanjing Rubber and Plastic Machinery Factory), the length-to-diameter ratio of the extruder is L:D=36:1, and the screw diameter is Φ53 mm. Adjust the rotation speed of the screw to 400 rpm, and divide it into 5 sections from the feed end to the discharge end, and control the temperature of each section at: 170°C; 175°C, 180°C, 185°C, 185°C; The vacuum degree of the mixture is maintained at 0.05 to 0.08 MPa; under the above conditions, through melt extrusion and granulation, mixture I is obtained; 80% titanate modified nickel powder, 4% titanate modified magne...

Embodiment 2

[0047] Mix 0.5% ethylene-octene copolymer, 0.5% EPDM, and 15% polyethylene resin, which account for positive temperature coefficient materials, to obtain a mixture, and send the above-mentioned mixture into a twin-screw compounding extruder (SJSH- Type 30, Nanjing Rubber and Plastic Machinery Factory), the length-to-diameter ratio of the extruder is L:D=36:1, and the screw diameter is Φ53 mm. Adjust the rotation speed of the screw to 400 rpm, and divide it into 5 sections from the feed end to the discharge end, and control the temperature of each section at: 170°C; 175°C, 180°C, 185°C, 185°C; Keep the vacuum degree of 0.05 to 0.08 MPa; under the above conditions, through melt extrusion granulation, to obtain the mixture I; 82% of titanate modified carbon black, titanate modified 1% of alumina in Mix at room temperature (25° C.), first at 800 rpm for 20 minutes, then at 2000 rpm for 3 minutes to obtain mixture II. Finally, mixture I, mixture II and 1% zinc stearate were mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com