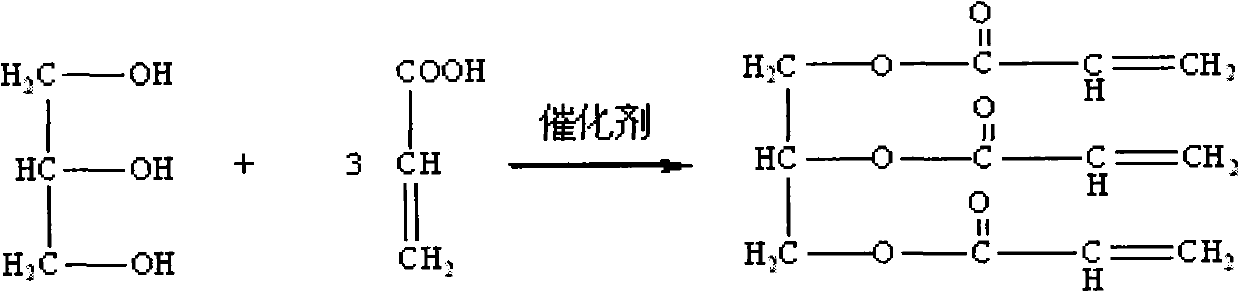

Preparation method of 1, 2, 3-glycerin triacrylate

A technology of glycerol triacrylate and glycerin, which is applied in the field 1, can solve problems such as equipment corrosion and cumbersome post-processing operations, and achieve the effects of reducing production costs, reducing pollution and equipment corrosion, and safe and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 0.2mol (18.4g) of 1,2,3-propanetriol, 0.7mol (50.4g) of acrylic acid, and 80ml of toluene as a water-carrying agent in a three-necked flask equipped with a reflux condenser, water separator, thermometer, and stirrer , the catalyst is silicotungstic acid 2.6g, the polymerization inhibitor is hydroquinone 1g, stir evenly and heat to 100°C, and react for 7 hours. The target product 1,2,3-propanetriol triacrylate was obtained after alkali neutralization and vacuum distillation.

Embodiment 2

[0018] Add 0.2mol (18.4g) of 1,2,3-propanetriol, 0.7mol (50.4g) of acrylic acid, and 80ml of toluene as a water-carrying agent in a three-necked flask equipped with a reflux condenser, water separator, thermometer, and stirrer , the catalyst is 3g of phosphotungstic acid, the polymerization inhibitor is 1.2g of hydroquinone, stir evenly and heat to 105°C, and react for 5 hours. The target product 1,2,3-propanetriol triacrylate was obtained after alkali neutralization and vacuum distillation.

Embodiment 3

[0020] Add 0.2mol (18.4g) of 1,2,3-propanetriol and 0.8mol (57.6g) of acrylic acid into a three-neck flask equipped with a reflux condenser, water separator, thermometer, and stirrer. 100ml, the catalyst is silicotungstic acid 3g, the polymerization inhibitor is hydroquinone 1.1g, stir evenly and heat to 95°C, and react for 6 hours. The target product 1,2,3-propanetriol triacrylate is obtained after alkali neutralization and then vacuum distillation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com