Optical glass, preform for precision press molding and manufacturing method of the same, optical element and manufacturing method of the same

A technology of optical glass and manufacturing method, which is applied in the direction of optical elements, glass molding, glass pressing, etc., can solve the problems of high-efficiency production hindrance, surface precision reduction, etc., and achieve the effect of high dispersion characteristics and high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13

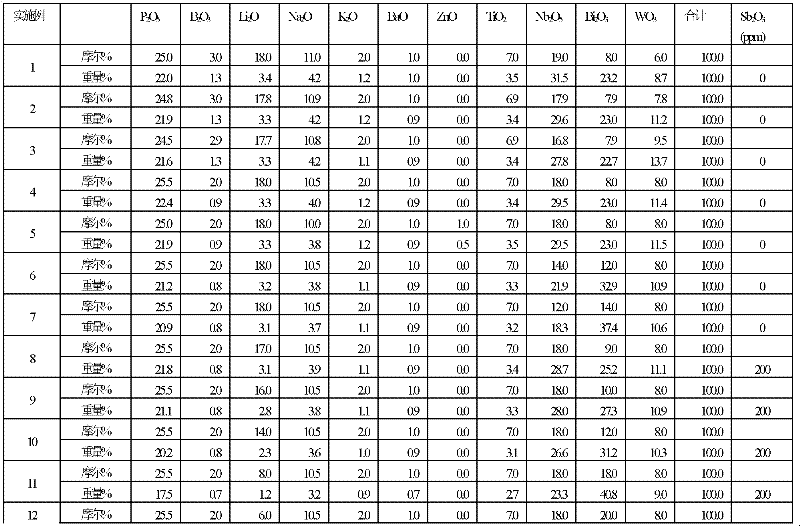

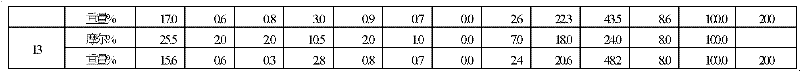

[0107] Tables 1 to 3 show the glass components and refractive index (n d ), dispersion coefficient (v d ), glass transition temperature (T g ), deformation point (T s ), liquidus temperature (LT), viscosity at liquidus temperature (LT viscosity), specific gravity, specific transmittance wavelength. All glasses use their corresponding oxides, hydroxides, carbonates and nitrates as ingredients. After vitrification, weigh the above-mentioned raw materials to form the ingredients shown in Table 1. After fully mixing, put Put it into a platinum crucible, melt it in the temperature range of 1000-1150 ℃ with an electric furnace, stir it to achieve uniformity, and pour it into a metal mold preheated to an appropriate temperature after clarification. Once the poured glass is cooled to the transition temperature, it is immediately put into the annealing furnace and annealed to room temperature to obtain various optical glasses. For the obtained optical glass, measure the refractive ...

Embodiment 14

[0129] Next, the clarified and homogenized molten glass corresponding to Examples 1 to 13 is flowed out at a constant flow rate, dripped or cut by a drop method from a platinum alloy tube whose temperature is adjusted to a temperature range where it can flow out stably without devitrification. Separating the molten glass block with the weight of the target preform, receiving the molten glass block with a support mold with a gas outlet at the bottom, and blowing out gas from the gas ejection port to form the glass block while floating Preforms for pressure molding. By adjusting and setting the separation interval of the molten glass, a spherical preform with a diameter of 2-30 mm can be obtained. The weight of the preforms is exactly the same as the set value, and the surface is smooth all the time.

[0130] Furthermore, the above-mentioned molten glass can also be poured into a mold to form a glass block, annealed, cut after reducing deformation, and made into a glass sheet, ...

Embodiment 15

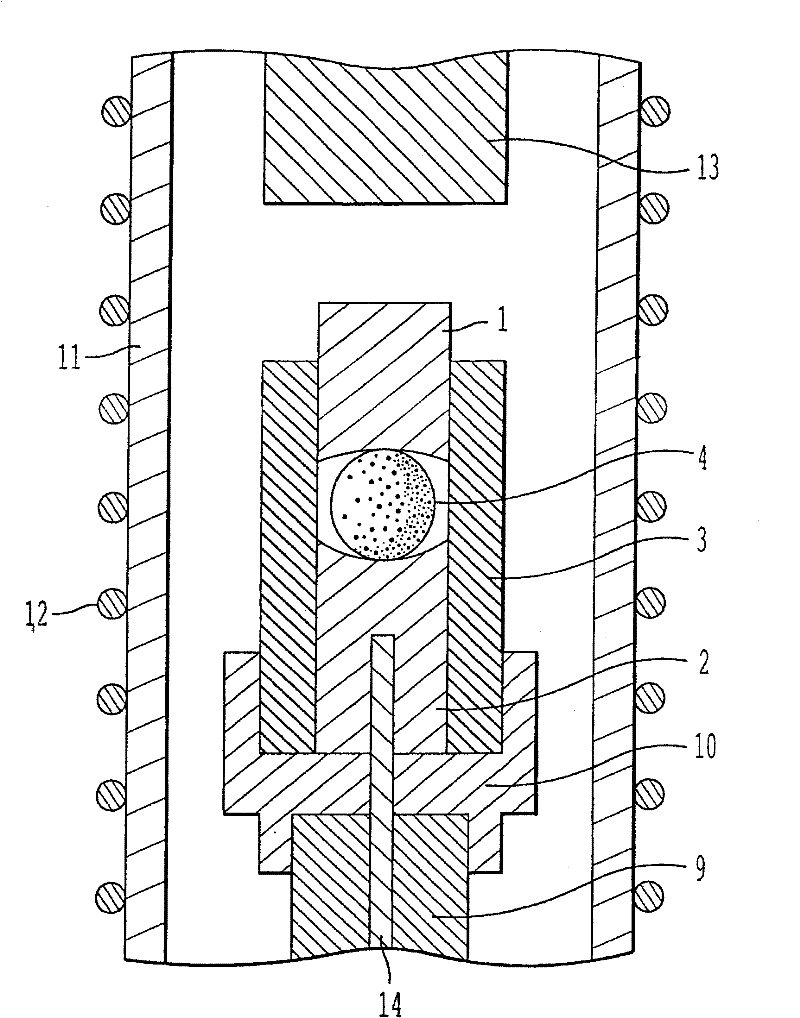

[0132] With the preform that embodiment 14 obtains, use figure 1 The pressing device shown is precisely press-molded to obtain an aspheric lens. Specifically, after the preform is placed between the lower mold 2 and the upper mold 1 constituting the pressure molding mold, the inside of the quartz tube 11 is made into a nitrogen atmosphere, and the heater 12 is energized to heat in the quartz tube 11. Set the temperature inside the pressure forming mold to the glass display 10 8 ~10 10 The temperature of dPa·s viscosity is maintained, and the pressure rod 13 is dropped to pressurize the upper mold 1 and pressurize the preform placed in the forming mold. The pressurized pressure was 8 Mpa, and the pressurized time was 30 seconds. After pressurization, the pressure is released, and the pressure-molded glass molded product is annealed in a state where the lower mold 2 and the upper mold 1 are in contact until the viscosity of the above-mentioned glass is 10. 12 dPa·s or higher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com