Method for manufacturing glued steel belt for steel-belt-reinforced plastic composite pipe

A technology of reinforced plastic and rubber-coated steel belt, which is applied in the field of steel-belt-reinforced plastic composite pipe rubber-coated steel belt manufacturing. It can solve problems such as difficult contact, insufficient roughness, and hot-melt adhesive can't be riveted, etc., to achieve roughness improvement. , Improve the bonding effect, and the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The manufacturing method includes the following steps in sequence:

[0019] 1) Clean the grease and dirt on the surface of the steel strip with detergent;

[0020] 2) Treat the surface of the steel strip with a sandblasting machine to form a large number of pits on the smooth steel strip surface;

[0021] 3) Use a set of brush rollers to remove dust and abrasives on the surface of the steel strip;

[0022] 4) The steel strip is heated rapidly by means of electromagnetic induction heating, and the temperature is 160°C to 180°C;

[0023] 5) The steel strip is coated with hot melt adhesive through the extruder;

[0024] 6) The steel strip coated with hot melt adhesive passes between a pair of rubber pressure rollers, and the pressure roller applies pressure perpendicular to the surface of the steel strip to the hot melt adhesive;

[0025] 7) Cool the rubberized steel strip to below 60°C with water, and wind it up.

Embodiment 2

[0027] The manufacturing method includes the following steps in sequence:

[0028] 1) Clean the grease and dirt on the surface of the steel strip with detergent;

[0029] 2) Rapidly heat the steel strip to 100℃~150℃ by means of electromagnetic induction heating;

[0030] 3) Treat the surface of the steel strip with a shot blasting machine to form a large number of pits on the surface of the smooth steel strip;

[0031] 4) Use compressed air to clean the dust and abrasives attached to the surface of the steel strip;

[0032] 5) The steel strip is rapidly heated to 180°C to 200°C by means of electromagnetic induction heating;

[0033] 6) The steel strip is coated with hot melt adhesive through the extruder;

[0034] 7) The steel strip coated with hot melt adhesive passes between three pairs of aluminum alloy pressure rollers, and the pressure rollers exert pressure perpendicular to the surface of the steel strip on the hot melt adhesive;

[0035] 8) Cool the rubberized steel...

Embodiment 3

[0037] The manufacturing method includes the following steps in sequence:

[0038] 1) Clean the grease and dirt on the surface of the steel strip with detergent;

[0039] 2) Rapidly heat the steel strip to 150°C to 200°C by means of electric heating;

[0040] 3) Treat the surface of the steel strip with a fluffing machine, so that a large number of burrs are formed on the surface of the smooth steel strip;

[0041] 4) Use compressed air to remove dust and residue attached to the surface of the steel strip;

[0042] 5) Rapidly heat the steel strip to 230°C to 250°C by means of electromagnetic induction heating;

[0043] 6) The steel strip is sprayed with polyolefin bonding resin powder by spraying equipment;

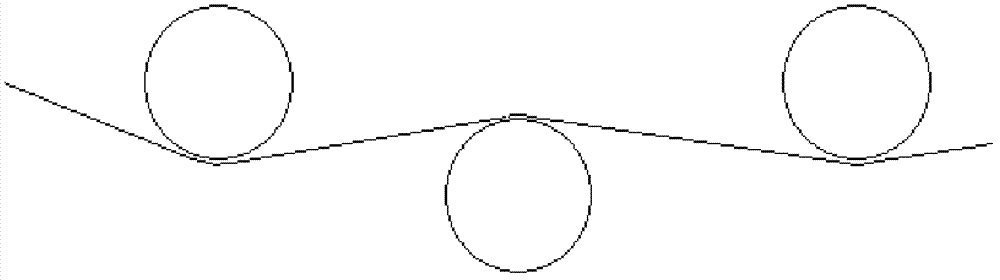

[0044] 7) The steel strip coated with hot melt adhesive passes sequentially through a set of stainless steel pressure rollers that are staggered up and down, and each pressure roller exerts a pressure perpendicular to the surface of the steel strip on the polyolefin ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com