Dynamic control method for slab continuous casting electromagnetic stirrer

An electromagnetic stirrer and dynamic control technology, which is applied in the field of iron and steel smelting and continuous casting, can solve the problems of inconsistency in billet quality and unstable stirring effect, and achieve a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

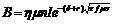

[0022] Using magnetic induction B Calculation formula for current and frequency determination.

[0023] The specific conditions are: control the electromagnetic stirrer in the secondary cooling zone of the 200×1450 mm slab continuous caster, and the electromagnetic stirrer is located 3.9m below the meniscus.

[0024] First of all, the continuous casting primary computer control system collects the actual process parameters of on-site continuous casting production according to the set program. The collected process parameters are: steel type 45# steel; slab thickness 200 mm, width 1450 mm; molten steel temperature 1507 °C; superheat degree 16 °C; casting speed 1.3 m / min. At the same time, the continuous casting primary computer transmits various real-time data collected to the continuous casting secondary computer;

[0025] The continuous casting secondary computer continuously processes the various measured data received from the primary computer according to the set program...

Embodiment 2

[0031] The current intensity and frequency are selected and controlled by using the recommended 200×1450 mm slab continuous caster slab unsolidified rate and the corresponding table of current intensity and frequency determined by the width of the mushy zone.

[0032] The electromagnetic stirrer is located 5.6m below the meniscus.

[0033] The continuous casting first-level computer control system collects the actual process parameters of on-site continuous casting production according to the set program. The collected process parameters are: steel grade 65Mn steel; slab section size 200×1280mm; molten steel temperature 1492°C; superheat 20°C; casting speed 1.1m / min. At the same time, the continuous casting primary computer transmits various real-time data collected to the continuous casting secondary computer.

[0034] The continuous casting secondary computer continuously processes the various measured data received from the primary computer according to the set program, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

| Coil turns | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com