Calcium heparin liposome preparation for injection

A technology of liposome preparation and heparin calcium, applied in the field of medicine, can solve the problem that no heparin calcium liposome preparation for injection is put on the market, the encapsulation rate of low molecular weight heparin nanoliposome is low, and no heparin calcium liposome is found. It can improve the bioavailability, good encapsulation efficiency and stability, and improve the quality of preparation products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

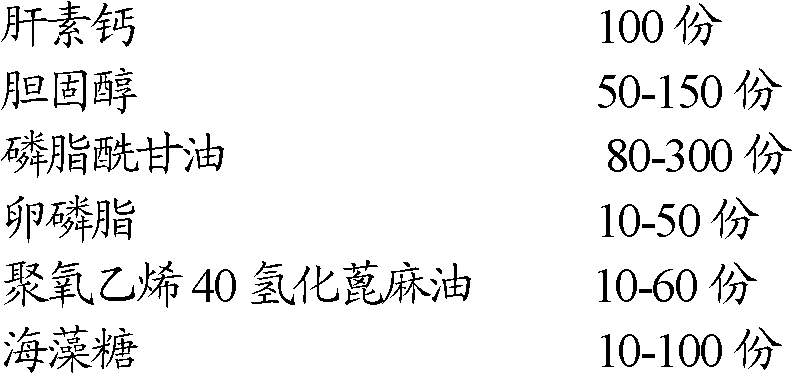

[0063] On the other hand, the present invention also provides a preparation method of heparin calcium liposome preparation for injection, which specifically includes the following preparation steps:

[0064] (1) Cholesterol, phosphatidylglycerol, lecithin and polyoxyethylene 40 hydrogenated castor oil are placed in a pear-shaped bottle, an organic solvent is added, heated and stirred to dissolve, and then the organic solvent is removed under reduced pressure on a rotary evaporator. A uniform and transparent phospholipid film is formed on the bottle wall;

[0065] (2) Under the protection of nitrogen, add the aqueous solution of heparin calcium and PVP into the bottle, stir to elute the phospholipid membrane and fully swell and hydrate. After the hydration is complete, do gradient homogenization at 100bar to 600bar for 4 to 6 times, 0.22μm Microporous membrane filtration to obtain heparin calcisomes;

[0066] (3) Under sterile conditions, dissolve trehalose and sorbitol in wat...

Embodiment 1

[0073] The preparation of embodiment 1 injection heparin calcium liposome preparation

[0074] The raw and auxiliary materials used and their weights are as follows (1000 bottles):

[0075]

[0076] Adopt preparation technology to prepare heparin calcium liposome preparation for injection:

[0077] (1) Put 90g of cholesterol, 150g of phosphatidylglycerol, 30g of lecithin and 20g of polyoxyethylene 40 hydrogenated castor oil in a pear-shaped bottle, add 10000ml of ethanol, heat and stir to dissolve it, and then remove it under reduced pressure on a rotary evaporator Organic solvent, forming a uniform and transparent phospholipid film on the bottle wall;

[0078] (2) Under the protection of nitrogen, add 100g heparin calcium and 30g PVP dissolved in 1200ml water for injection to the bottle, stir to elute the phospholipid film and fully swell and hydrate it. After the hydration is complete, do gradient homogenization at 100bar to 600bar 4 to 6 times, 0.22 μm microporous me...

Embodiment 2

[0080] The preparation of embodiment 2 injection heparin calcium liposome preparation

[0081] The raw and auxiliary materials used and their weights are as follows (1000 bottles):

[0082]

[0083] Adopt preparation technology to prepare heparin calcium liposome preparation for injection:

[0084] (1) Put 95g of cholesterol, 165g of phosphatidylglycerol, 35g of lecithin and 30g of polyoxyethylene 40 hydrogenated castor oil in a pear-shaped bottle, add 10000ml of ethanol, heat and stir to dissolve it, and then remove it under reduced pressure on a rotary evaporator Organic solvent, forming a uniform and transparent phospholipid film on the bottle wall;

[0085] (2) Under the protection of nitrogen, add 100g heparin calcium and 55g PVP dissolved in 1200ml water for injection to the bottle, stir to elute the phospholipid membrane and fully swell and hydrate it. After the hydration is complete, do gradient homogenization at 100bar to 600bar 4 to 6 times, 0.22 μm microporou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com