Liquid-cooled cooling plate with composite casting structure

A liquid-cooled cold plate and composite casting technology, which is applied in cooling/ventilation/heating transformation, heat exchange equipment, lighting and heating equipment, etc., can solve weld cracking, poor corrosion resistance of coolant, and liquid-cooled cold plate contact heat Large resistance and other problems, to achieve the effect of small contact thermal resistance, not easy to leak, and improve heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

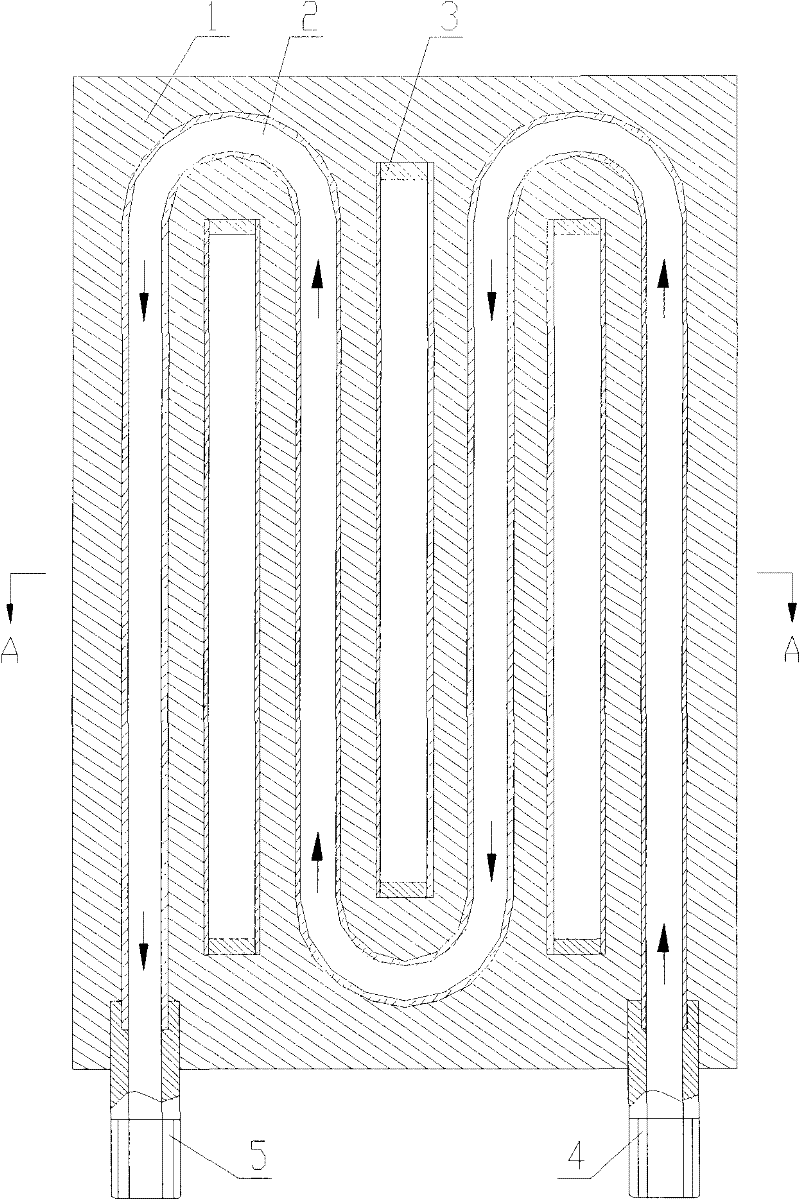

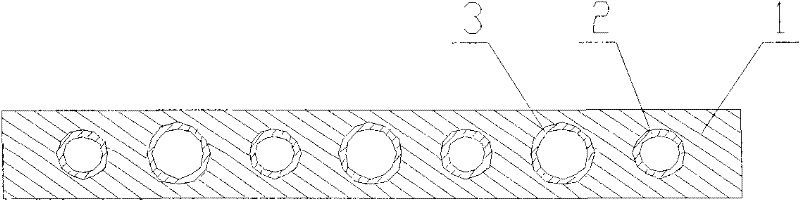

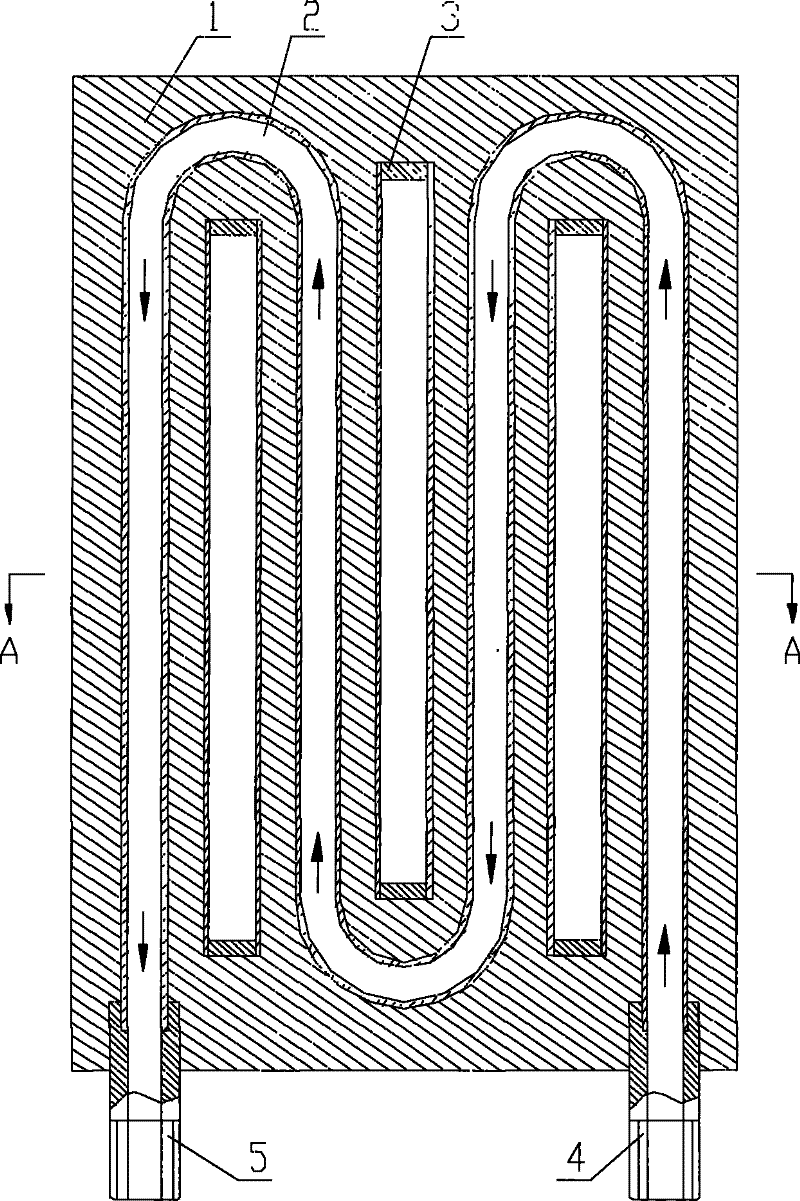

[0011] A liquid-cooled cold plate with a composite casting structure, comprising: a cast aluminum alloy base plate 1, and further comprising: a coil pipe 2, a pipe joint A4, a pipe joint B5 and a pipeline 3.

[0012] The cast aluminum alloy bottom plate 1 is the base of the liquid-cooled cold plate, which is a rectangular flat plate. The base material is aluminum-magnesium-silicon cast aluminum alloy, and the coil tube 2 is an "M"-shaped seamless stainless steel tube; pipe joint A4 and pipe joint B5 It is a stainless steel pipe, and the pipeline 3 is a straight stainless steel pipe with both ends closed. The coil 3 , the pipe joint A4 , the pipe joint B5 and the pipeline 3 are placed in the cast aluminum alloy base plate 1 and fixed with the cast aluminum alloy base plate 1 . The two ports of the coil 2 are respectively welded and fixed with the pipe joint A4 and the pipe joint B5. The threaded joints of the pipe joint A4 and the pipe joint B5 are higher than the end face of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com