Radial magnetic field motor with amorphous alloy

A technology of amorphous alloy and radial magnetic field, applied in the direction of static components of magnetic circuit, magnetic circuit shape/style/structure, magnetic circuit characterized by magnetic materials, etc., can solve the problem of long processing time and large-scale motor Amorphous alloy thin strip size limitation, many additional processes and other problems, to get rid of the restrictions, avoid the hidden dangers of recrystallization and additional stress, and reduce the effect of reprocessing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

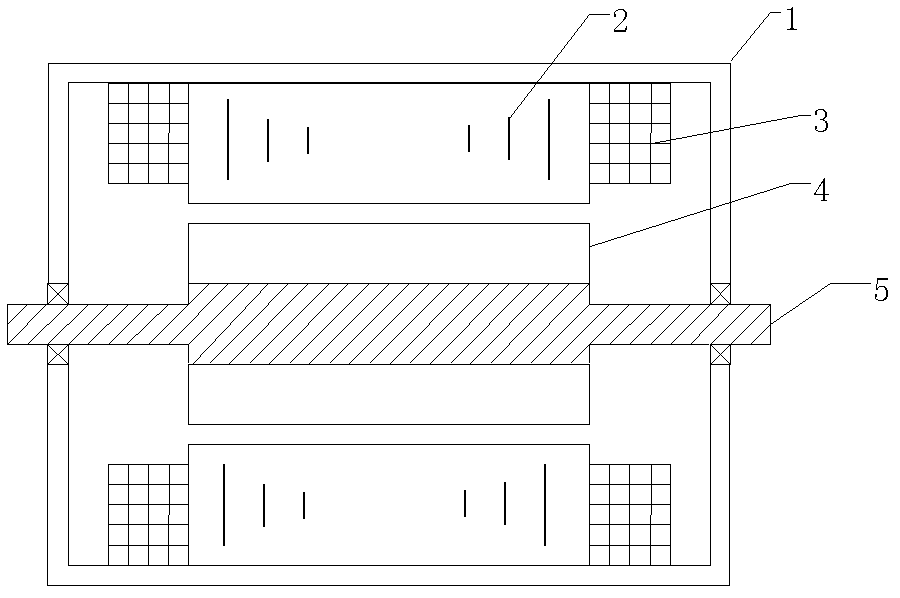

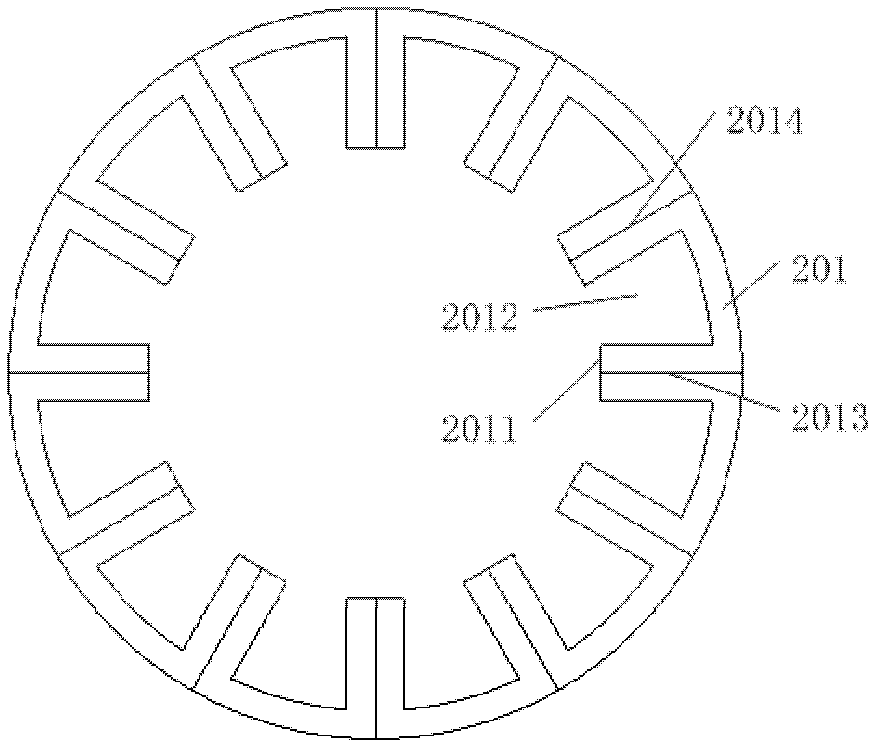

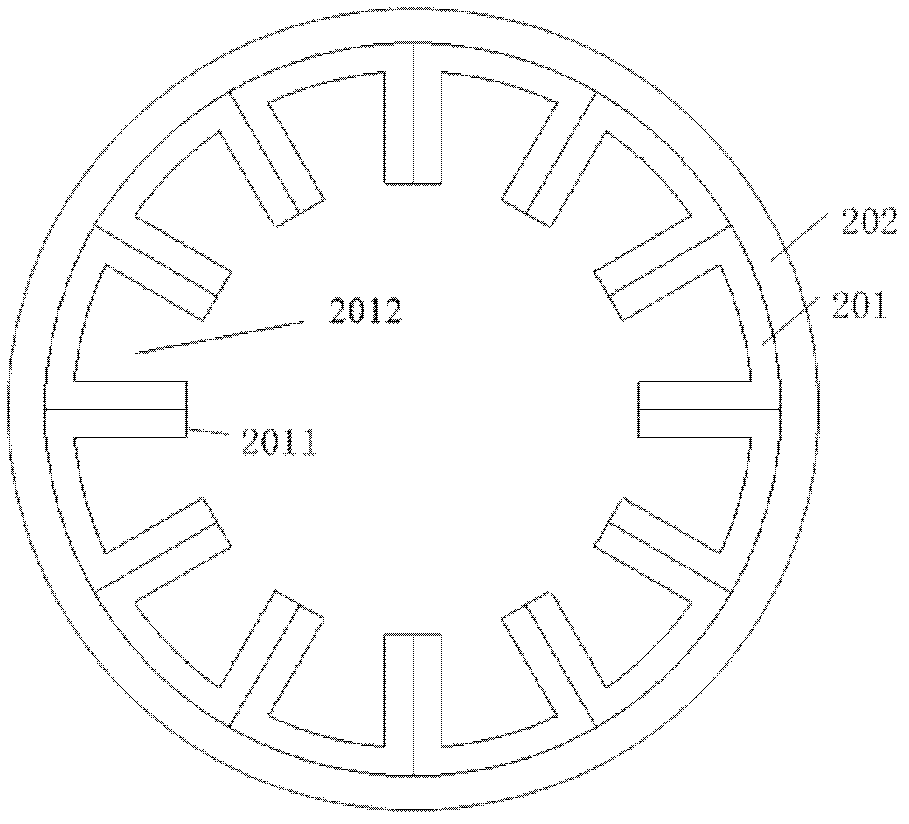

[0028] Such as figure 1 , figure 2 , Figure 3a , Figure 3bAs shown, the radial magnetic field amorphous alloy motor proposed by the present invention includes a casing 1 , a stator core 2 , an armature winding 3 , a rotor 4 and a rotor shaft 5 . The stator core 2 includes n×Q U-shaped amorphous alloy iron cores 201, and the n×Q U-shaped amorphous alloy iron cores 201 are divided into n groups of U-shaped amorphous alloy iron cores 201 stacked in the axial direction, each The group of Q U-shaped amorphous alloy iron cores 201 is arranged in a ring, n is an integer greater than or equal to 1, and Q is the number of stator slots.

[0029] Such as figure 2 , Figure 3a , Figure 3b As shown, the opening faces 2011 of each group of Q U-shaped amorphous alloy iron cores face inward, that is, the opening faces of the U-shaped amorphous allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com