Stripping liquid for removing residual photoresist in semiconductor technology

A stripping solution and semiconductor technology, applied in the field of cleaning agents, can solve problems such as affecting production safety, affecting operation, and affecting degumming, etc., and achieves the effect of effective clean removal and wide applicable temperature range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

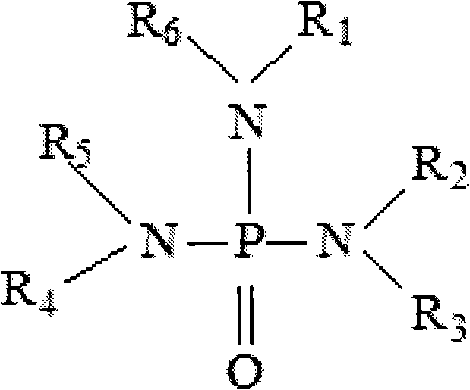

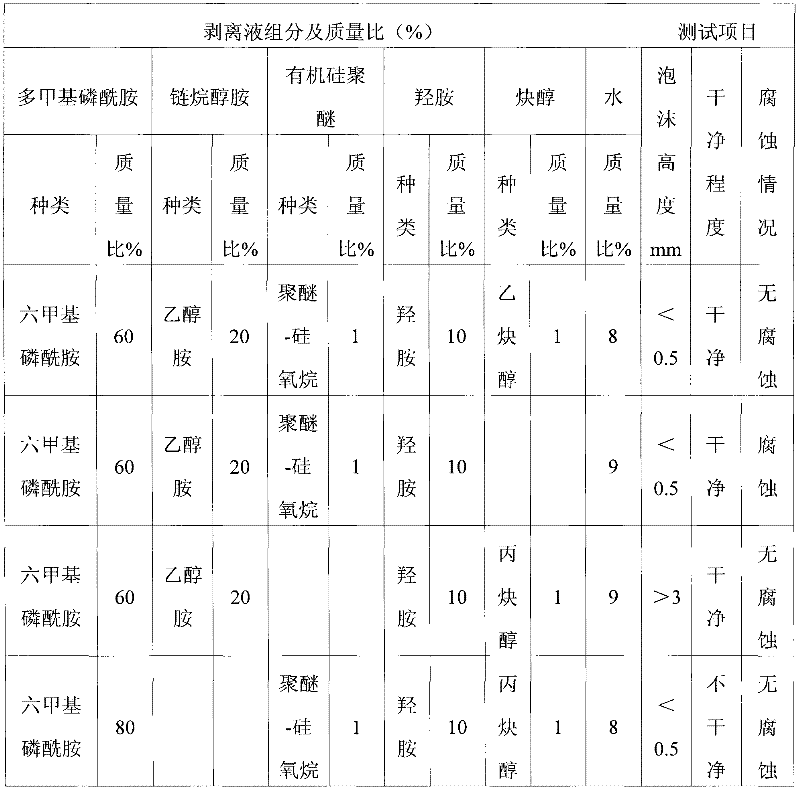

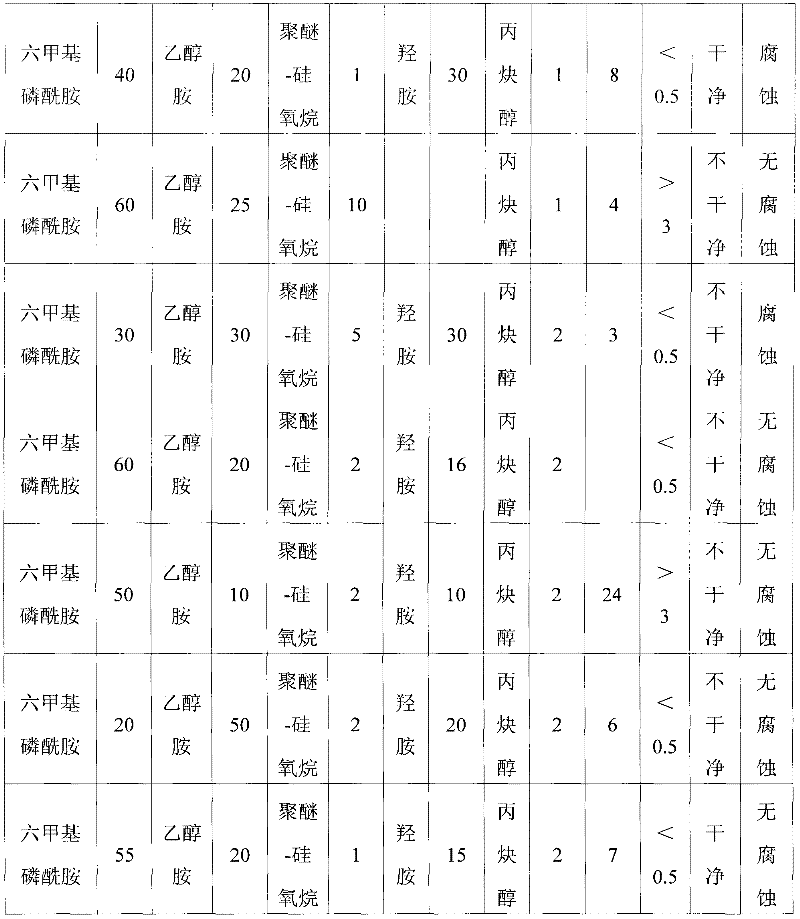

[0031] In the stripping solution of the present invention, the polymethylphosphoramide is preferably hexamethylphosphoramide, and the mass percentage content is preferably 10-70%. The hexamethylphosphoramide compound has a flash point of >100°C and a boiling point of 235°C, and has a strong dissolution effect on photoresists. When the mass percentage of hexamethylphosphoramide is lower than 10% or higher than 70%, the residual polymer after dry etching cannot be effectively removed.

[0032] Among them, the alkanolamine is preferably ethanolamine, and the mass percentage content is preferably 5-30%. When the ethanolamine content is lower than 5% or higher than 30%, the residual polymer after dry etching cannot be effectively removed.

[0033] The organosilicon polyether compound is preferably a polyether-siloxane copolymer with a weight average molecular weight below 1000, and the mass percentage content is preferably 0.01-10%. This modified organosilicon polyether has the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com