Double-layer air distribution method for fluidized bed dryer and equipment

A fluidized bed drying and fluidized air technology, which is applied in the directions of drying gas arrangement, drying solid materials, lighting and heating equipment, etc., can solve the problems of uneven fluidization, less material, dead bed, etc. Simple, less deadly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

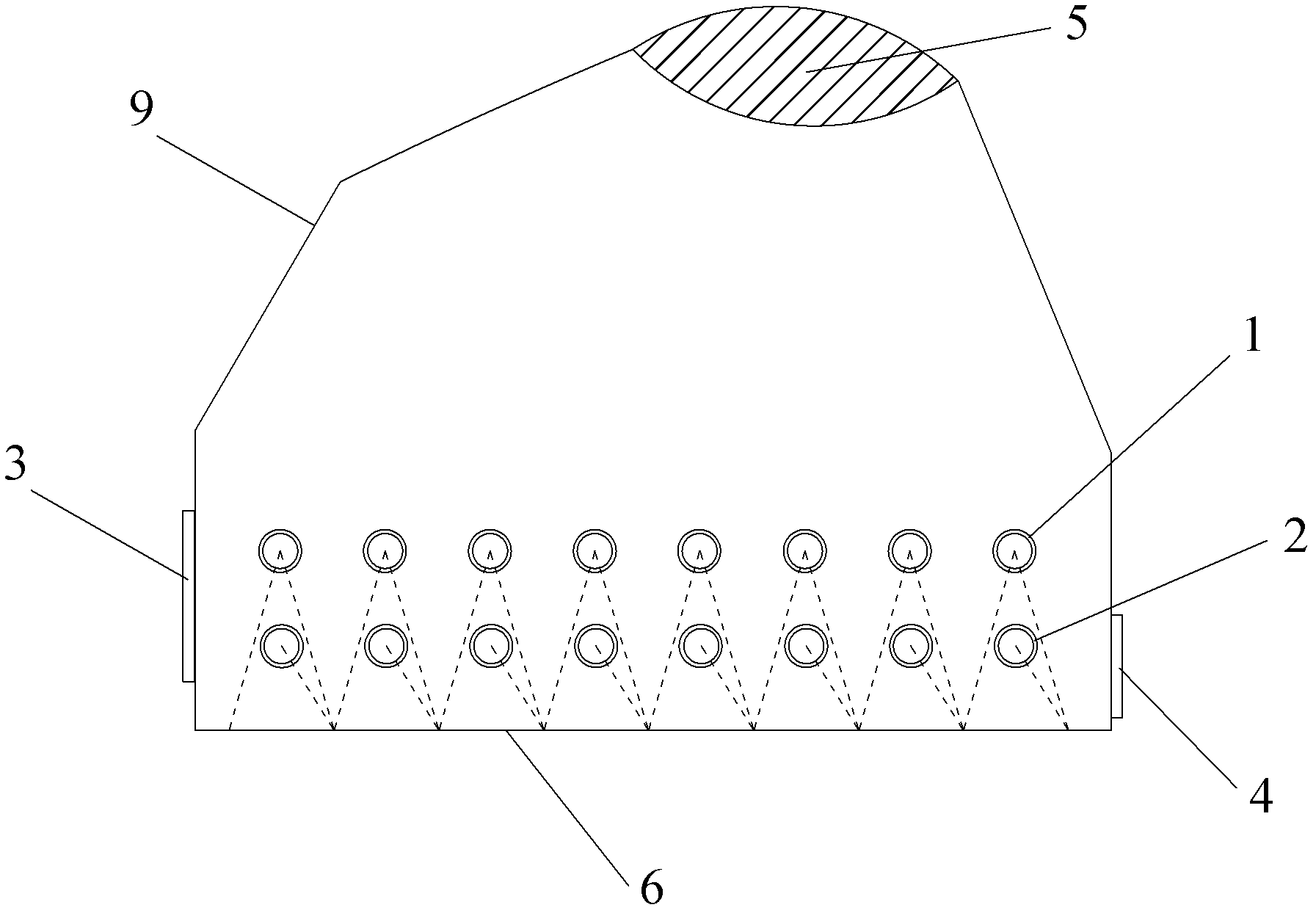

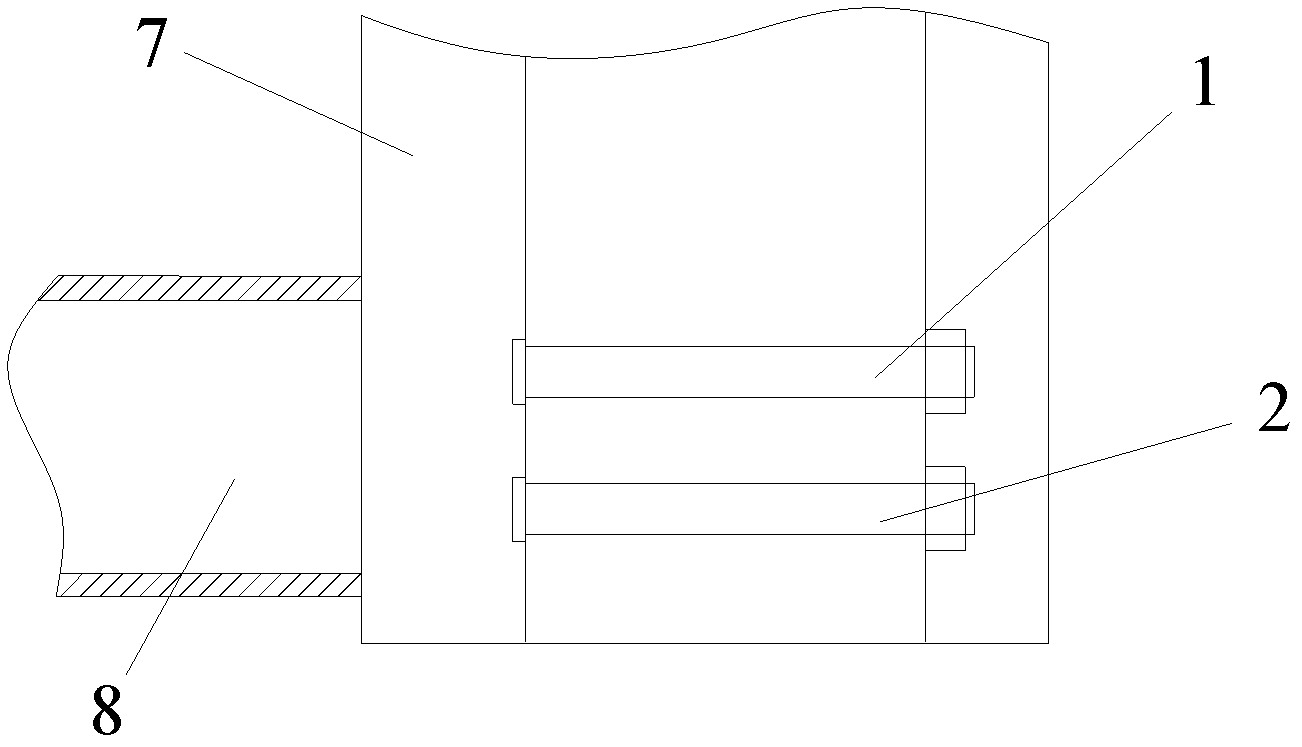

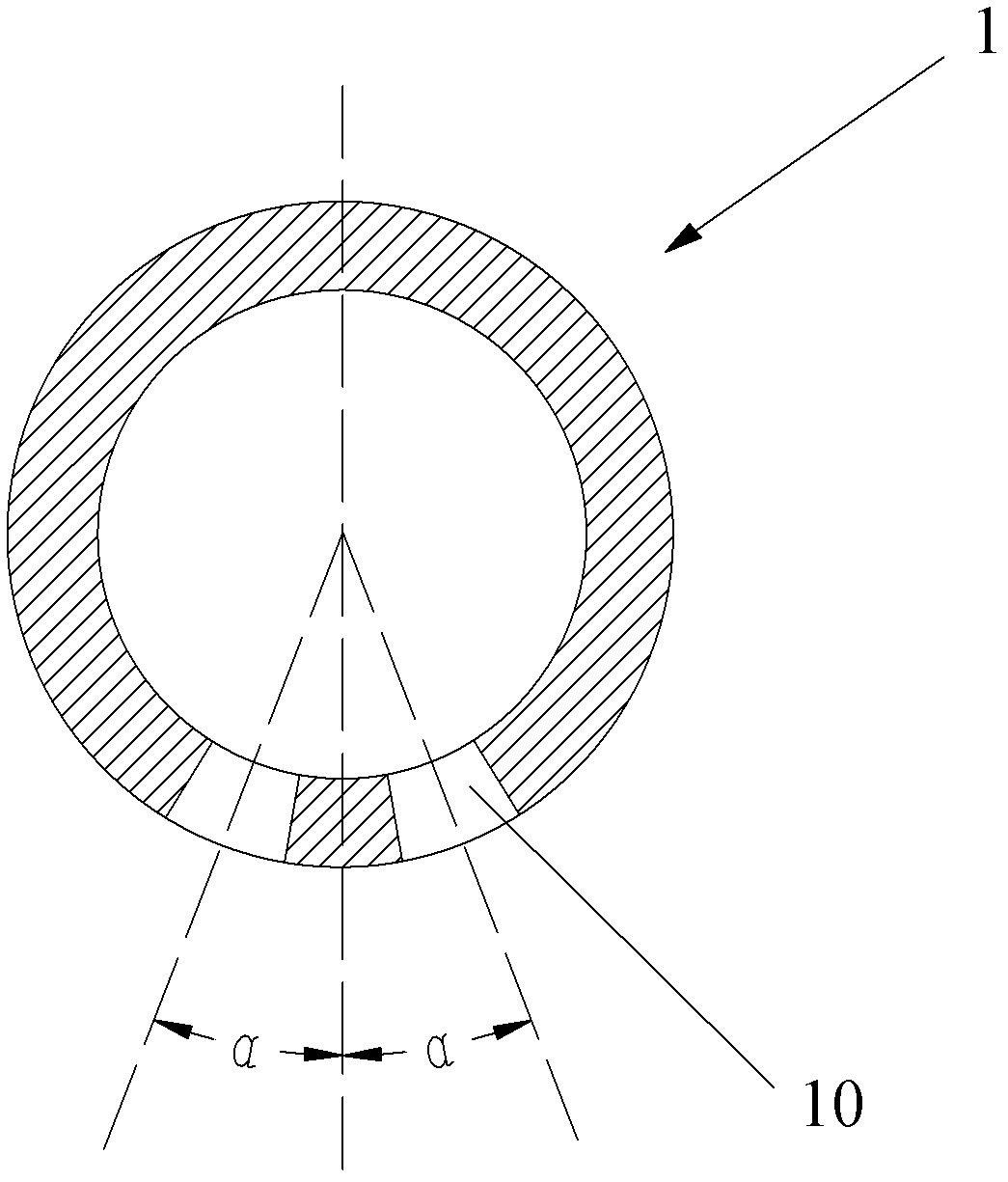

[0022] Such as Figure 1~6 As shown, the present invention provides a fluidized bed dryer using a double-layer air distribution method. It includes a fluidization chamber 9, the two ends of the fluidized bed bottom plate 6 of the fluidization chamber 9 are respectively provided with a feed port 3 and a discharge port 4, the top of the fluidization chamber 9 is provided with a powder outlet 5, the fluidization chamber 9 An air chamber 7 is arranged on the side, and the air chamber 7 is connected with the total air inlet pipe 8 . In the fluidization chamber 9, a row of upper-layer air distribution pipes 1 and a row of lower-layer air distribution pipes 2 connected to the air chamber 7 are arranged horizontally between the feed port 3 and the discharge port 4, and a row of upper-layer air distribution pipes 1 and A row of lower-layer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com