Solar power generation high-temperature vacuum heat collection tube with built-in expansion joint

A technology of vacuum heat collecting tubes and expansion joints, which is applied in the field of high temperature vacuum heat collecting tubes with built-in solar power generation in expansion joints, which can solve the problems of heat loss, affecting the heat absorption efficiency of heat collecting tubes, reducing the effective length of heat absorbing tubes, etc., to ensure long life work, avoid direct contact, and ensure the effect of vacuum life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

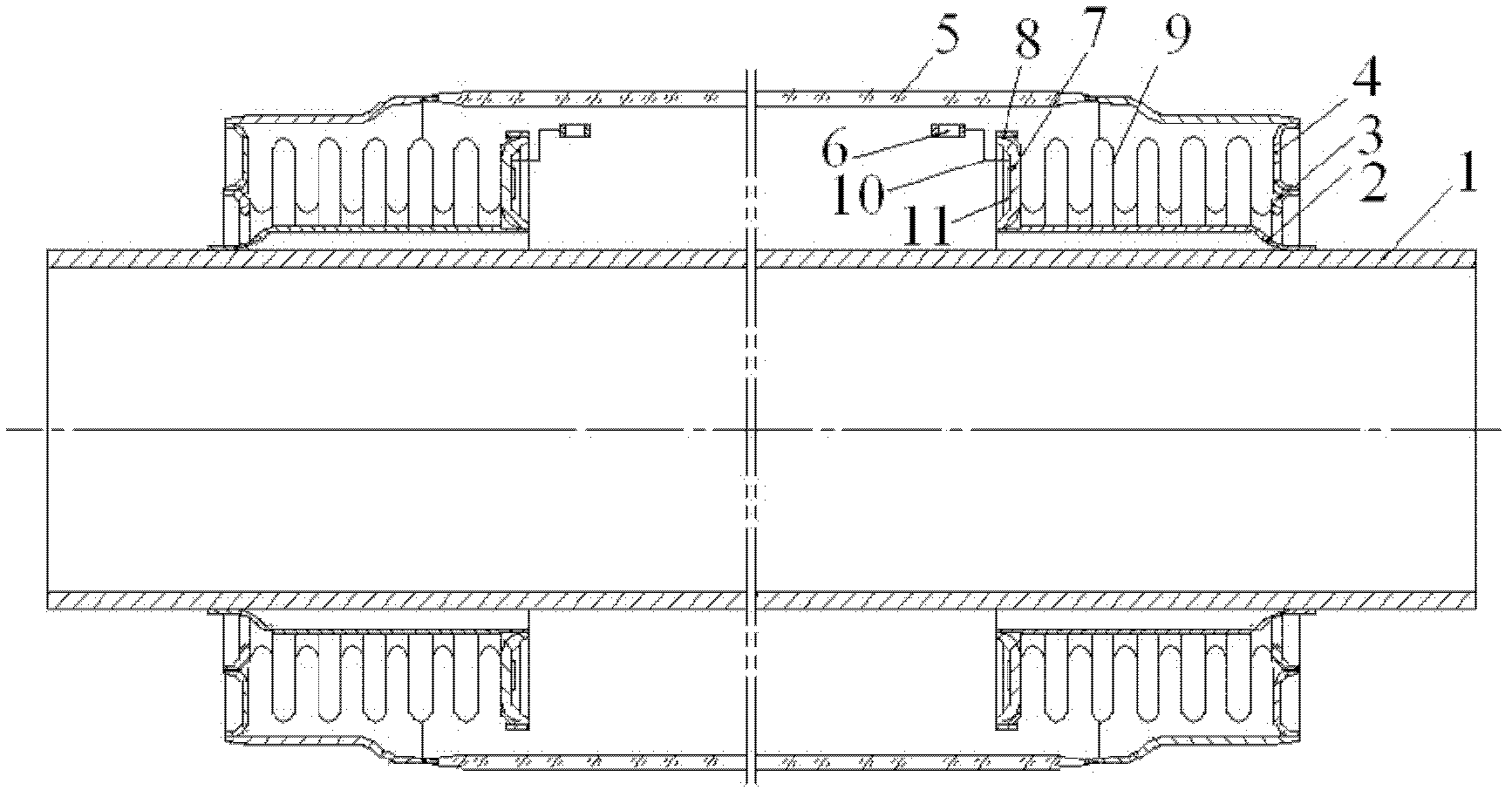

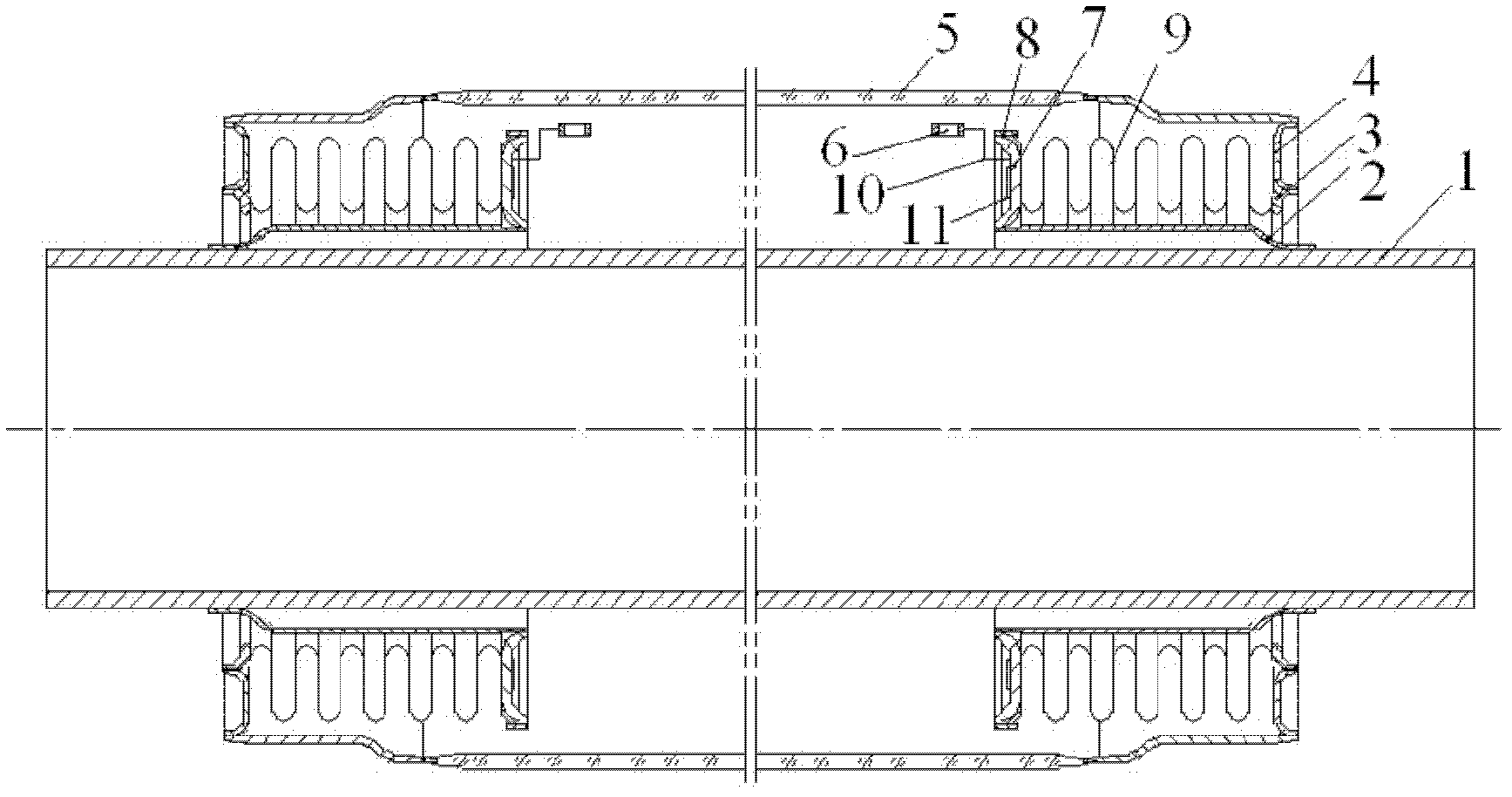

[0018] The structure of the built-in solar power generation high temperature vacuum heat collecting tube of the present invention is as follows: figure 1 As shown, the heat pipe 1 is welded to the shield 2, the shield 2 is welded to the inner hole of the lower cover 7, one end of the expansion joint 9 is directly welded to the lower cover 7, and the other end of the expansion joint 9 is welded to the upper cover 4. The inner hole is welded, the outer circle of the upper cover plate 4 is welded with a glass-metal sealing shell 5, and the glass-metal sealing shell 5 is welded with an evaporative getter 6 through a connecting piece 10, and one end of the connecting piece 10 is welded to the lower cover plate 7 superior. The non-evaporable getter 11 is spot-welded on the lower cover plate 7 . The inner hole of the expansion joint 9 is welded to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com