Method for increasing permeability of inert gas and extracting gas

A technology of inert gas and gas extraction, which is applied in gas discharge, mining equipment, earthwork drilling, etc., and can solve the problems of difficult gas desorption and poor anti-reflection effect of coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

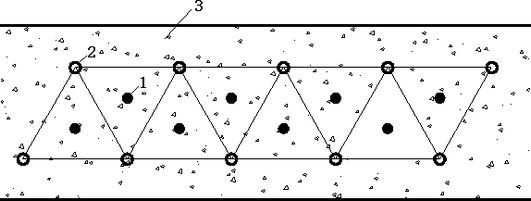

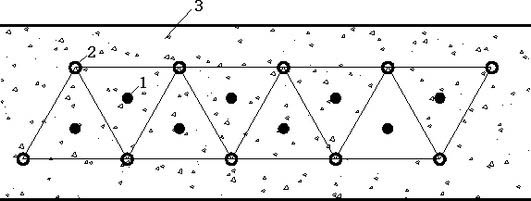

[0017] Embodiment 1: A method of the present invention for anti-reflection gas extraction with warm-pressed inert gas. Boreholes are arranged in the middle of the coal seam of the working face as the anti-reflection hole 1, and the depth of the anti-reflection hole 1 is 50m to 80m; the anti-reflection hole 1 is used as the The gas drainage hole 2 is arranged on the apex of the equilateral triangle in the center, and the depth of the gas drainage hole 2 is greater than half of the width of the working face, so as to avoid the appearance of a "blank zone" in drainage. Each gas drainage hole 2 is sealed by a conventional method, and the borehole is connected to an underground drainage system through gas drainage pipes and branch pipes to extract gas from the coal seam. The negative pressure at the borehole opening is not lower than 13KPa, and an observation hole is provided on the gas drainage pipe to measure the flow rate.

[0018] Use high-pressure grouting to seal the anti-ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com