Method and device for preparing bacterial cellulose composite material quickly on large scale

A technology of bacterial cellulose and composite materials, applied in biochemical equipment and methods, microorganism-based methods, biochemical cleaning devices, etc. The effect of shortening the production cycle, long cycle and cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Bacteria culture

[0053] Insert Acetobacter xylinum into 300mL liquid medium (per 1L of water, 20g of mannitol, 3g of peptone, 5g of yeast extract, pH 3.0, sterilized at 121°C for 20min; or 200g of glucose, 5g of yeast extract, Tryptone 5g, citric acid 115g, Na 2 HPO 4 2.7g, 1L of water, pH 7.5, sterilized at 121°C for 20min) for expansion, cultured on a shaking table at 20°C, 100r / min or standing for 12h before use;

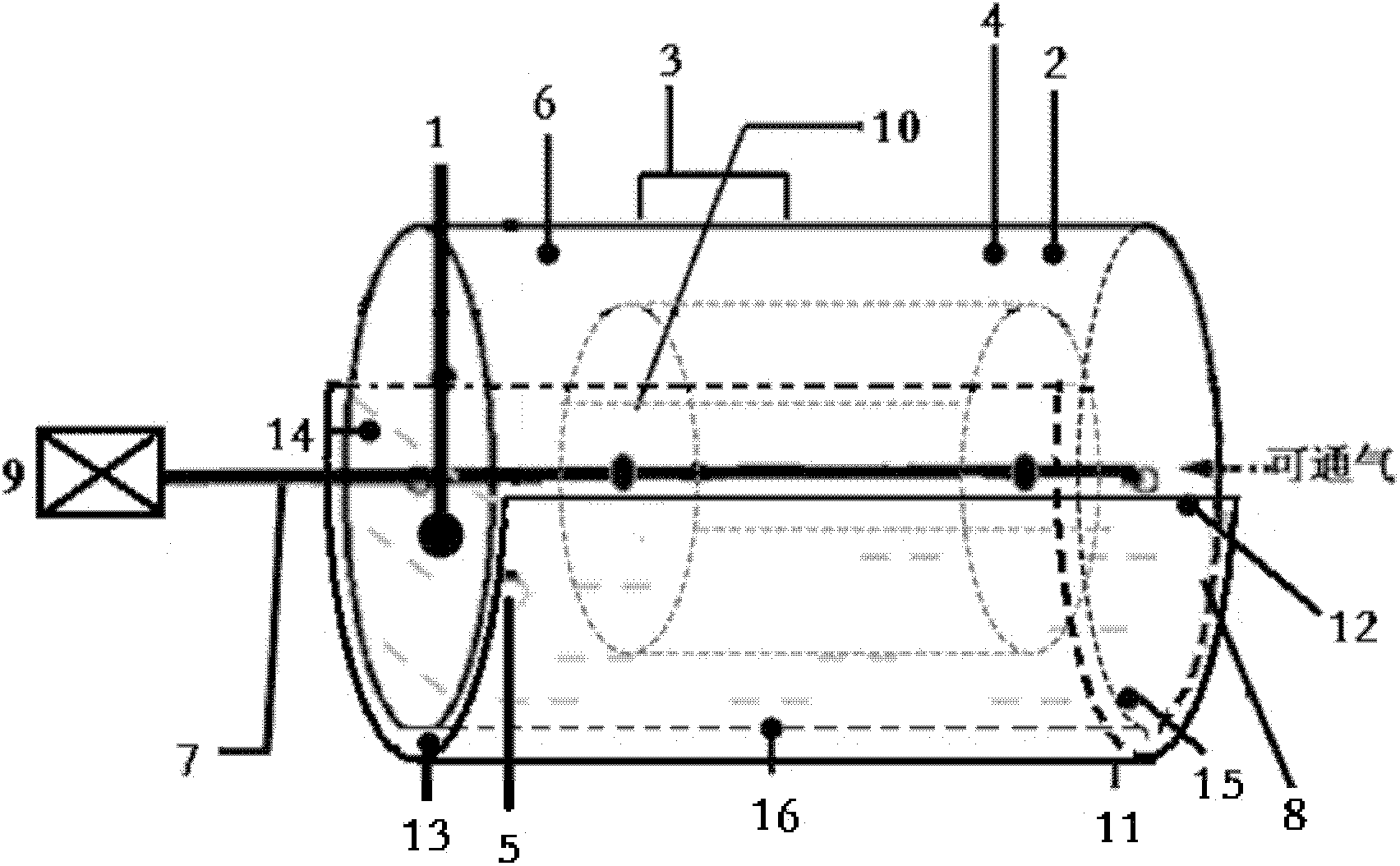

[0054] (2) Fermentation preparation of bacterial cellulose composite membrane

[0055] The liquid culture medium containing the production strain prepared in step (1) is transferred to a bioreactor equipped with a fixed gauze or silk skeleton material drum, and then the drum rotates at a speed of 7, 15, 30 and 60rpm for disturbance cultivation , after dynamic culture at 30°C for 1 day, the bacterial cellulose / gauze or bacterial cellulose / silk composite film can be obtained, and the film formation conditions are shown in Table 1; On the skeleton m...

Embodiment 2

[0066] (1) Bacteria culture

[0067] Put kombucha (kombucha) into 300mL liquid seed culture medium according to the inoculation amount of 1-10 discs with a diameter of 0.5cm containing bacteria BC membrane (per 1L of water, green tea 5g, glucose 10, peptone 3g, yeast extract 5g , pH3.0, pasteurized for 30min; per 1L of water, 100g of glucose, 3g of peptone, 5g of yeast extract, pH7.5, sterilized at 121°C for 20min) to expand the culture, shake the table at 25°C and 150r / min Cultivate or statically cultivate for 24 hours before use;

[0068] (2) Fermentation preparation of bacterial cellulose composite membrane

[0069] The liquid medium containing the production strain prepared in step (1) is transferred to a bioreactor equipped with a drum of polyester, nylon or polypropylene fiber skeleton material, and then the rotating drum is disturbed and cultivated at a speed of 15 or 25rpm. After 10 days of dynamic culture at 30°C, the film-forming product can be harvested;

[0070]...

Embodiment 3

[0076] (1) Bacteria culture

[0077] Insert Gluconacetobacter xylinus into 300mL liquid medium (per 1L of water, maltose 100g, peptone 3g, yeast extract 5g, pH 4.5, sterilized at 121°C for 20min; or fructose 160g, yeast extract 5g, tryptone 5g, citric acid 1.15g, Na 2 HPO 4 2.7g, 1L of water, pH 6.0, sterilized at 121°C for 20min) for expansion, cultured on a shaking table at 30°C, 250r / min or standing for 48h before use;

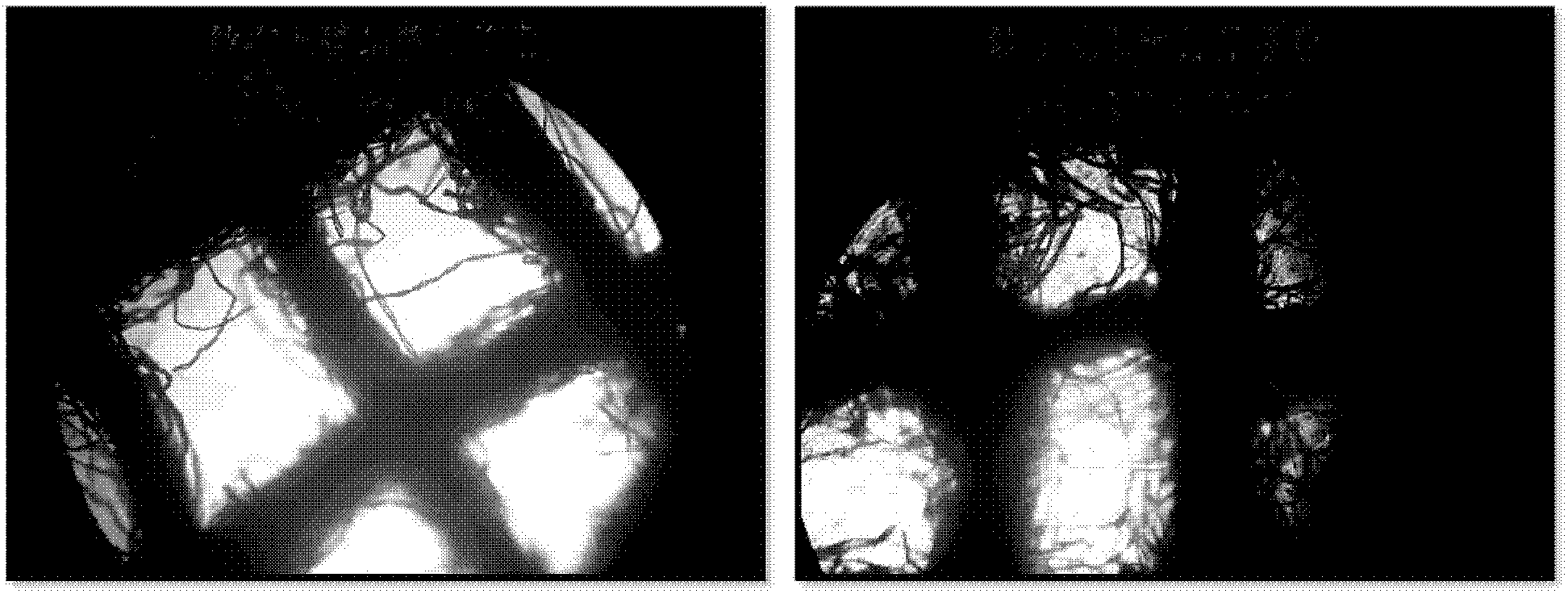

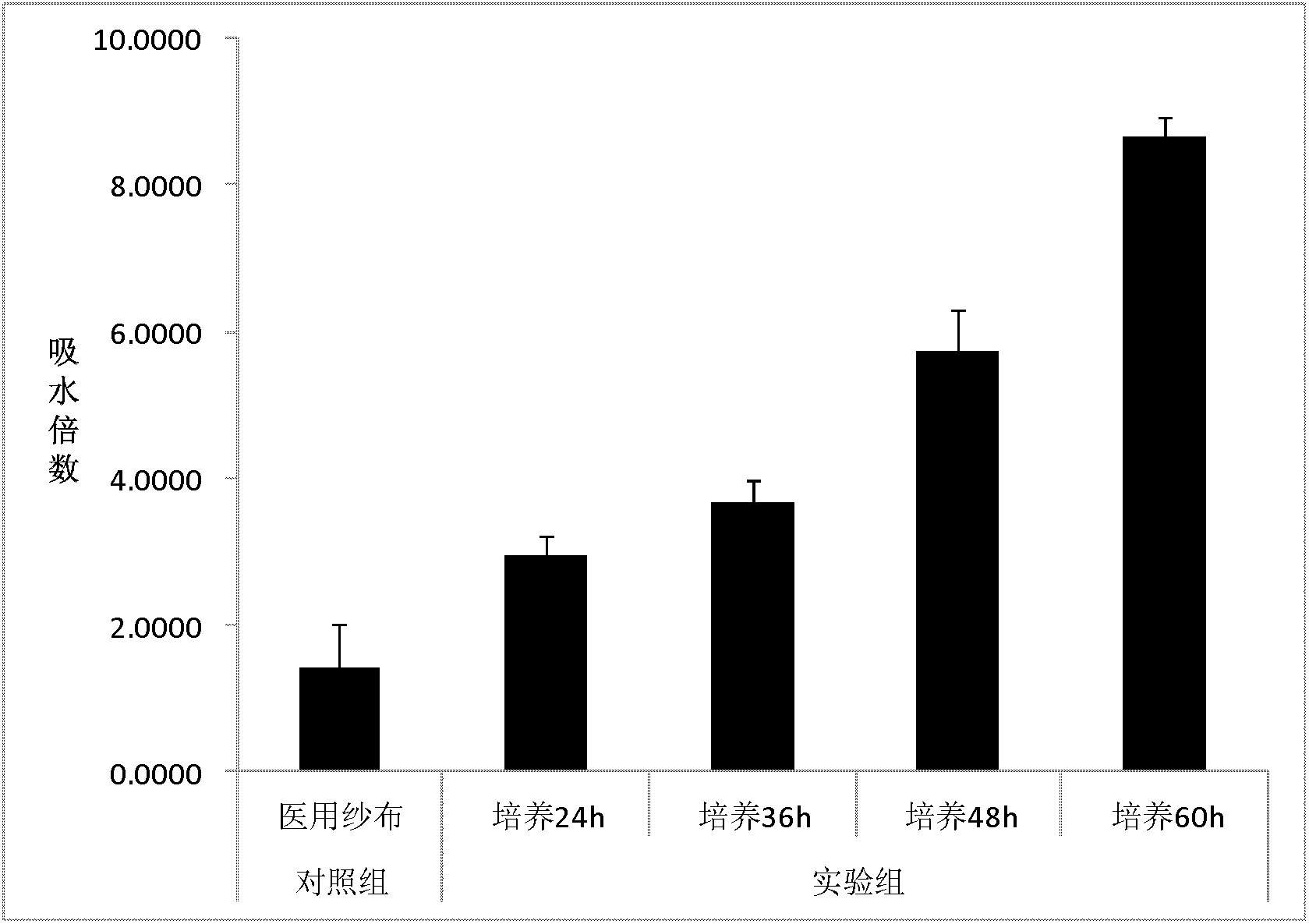

[0078] (2) Fermentation preparation of bacterial cellulose composite membrane

[0079] Transfer the liquid culture medium containing the production strain prepared in step (1) to a bioreactor equipped with a titanium dioxide metal mesh drum, then rotate the drum at a speed of 15 rpm for disturbed culture, and culture at 30°C for 24h and 36h respectively After 48h and 60h, the bacterial cellulose / titanium dioxide composite membrane can be obtained;

[0080] Or get the activated bacterial classification of step (1) to insert in the 300mL liquid fermentati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com