Method and device for coal gasification in combined type fluidized bed

A fluidized bed gasification, fluidized bed technology, applied in the field of coal gasification, can solve the problems of fluidized bed carbon utilization rate decline, low carbon conversion rate, short reaction time, etc., to improve gasification efficiency and processing capacity, The effect of low carbon content in ash discharge and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

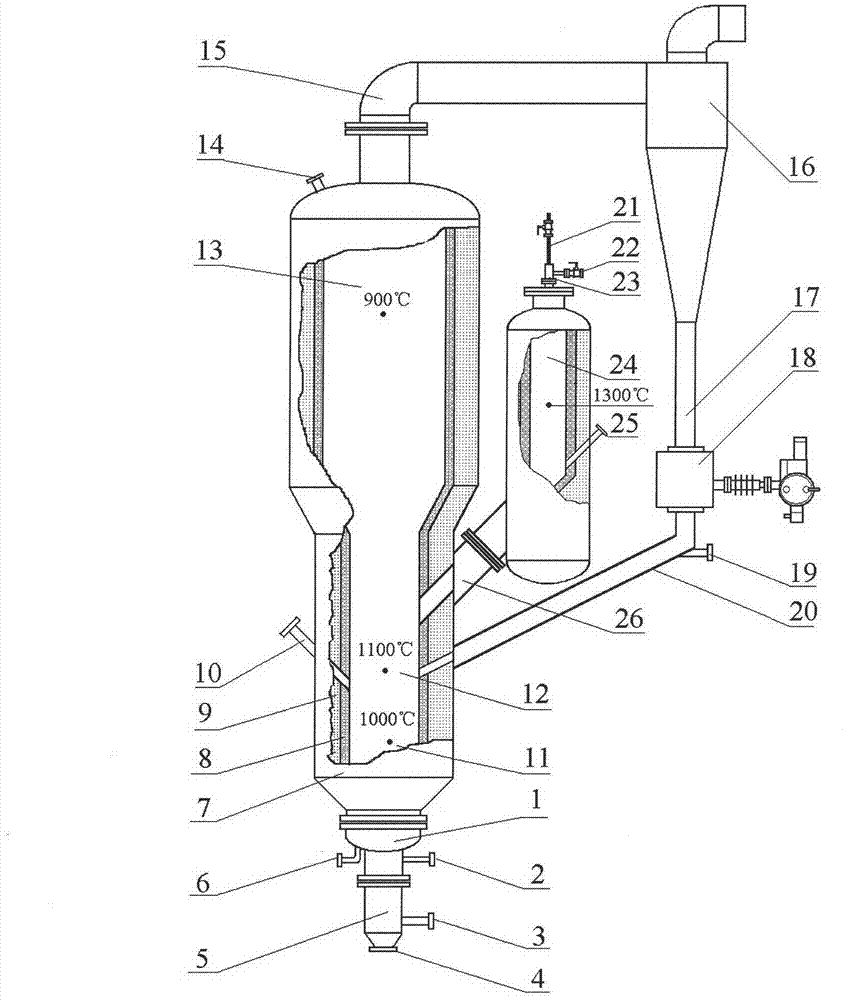

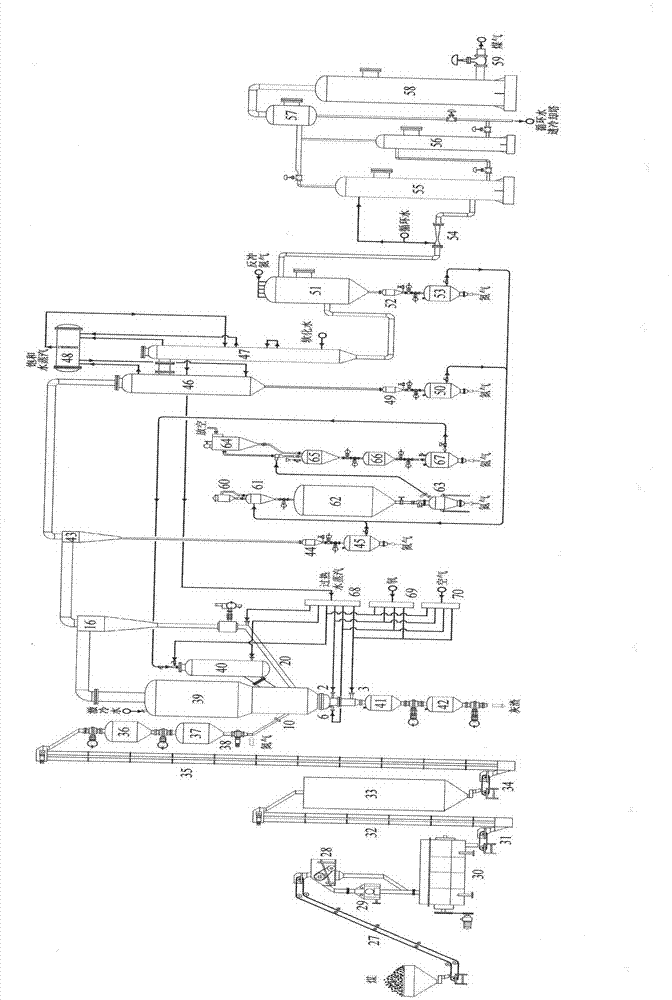

[0046] The composite fluidized bed gasification device is composed of a composite fluidized bed coal gasification furnace and a semi-coke fine powder circulation device. The composite fluidized bed coal gasification furnace is composed of a fluidized bed and an entrained flow bed. The bed is composed of a fluidized bed furnace body, a gasifier gas outlet pipe 15, a gas distributor 1 and an annular separation ash fall pipe 5, and the fluidized bed furnace body is made of a steel furnace shell 7, refractory material 8 and thermal insulation material 9 , the insulation material 9 is located between the steel furnace shell 7 and the refractory material 8, the top of the fluidized bed furnace body has a gasifier gas outlet 15 and furnace top quenching water pipe 14, and the lower part of the fluidized bed furnace body has a coal feed pipe 10 , the bottom of the fluidized bed furnace body is connected to a gas distributor 1, the gas distributor 1 has a central tube gasification agent...

Embodiment 2

[0053] The fluidized bed coal feed rate is 2300kg / h, and the oxygen feed rate is 1100Nm 3 / h, the water vapor volume is 2000kg / h, the fine powder feed volume of the entrained bed is 400kg / h, and the ratio of oxygen to dry coal powder is 0.53Nm 3 / kg, steam-coal ratio 0.16kg / kg, the pressure of the gasifier is controlled at 1.0MPa, the temperature at the bottom of the fluidized bed gasifier is stable at 980°C, the operating temperature of the entrained bed part is at 1250°C, the fluidized bed and entrained bed The junction temperature is 1100°C. All the other are with embodiment 1.

Embodiment 3

[0055] The fluidized bed coal feed rate is 2800kg / h, and the oxygen feed rate is 1380Nm 3 / h, the water vapor volume is 2700kg / h, the fine powder feed volume of the entrained bed is 600kg / h, and the ratio of oxygen to dry coal powder is 0.55Nm 3 / kg, steam-coal ratio 0.16kg / kg, the pressure of the gasifier is controlled at 1.5MPa, the temperature at the bottom of the fluidized bed gasifier is stable at 1000°C, the operating temperature of the entrained bed part is at 1200°C, the fluidized bed and entrained bed The junction temperature is 1090°C. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com