Solvent-free type fiber reinforced epoxy paint and preparation method thereof

An epoxy coating and fiber reinforced technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of unsatisfactory cracking resistance and impact resistance, and achieve the effects of excellent cracking resistance, long anti-corrosion life and simple surface treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

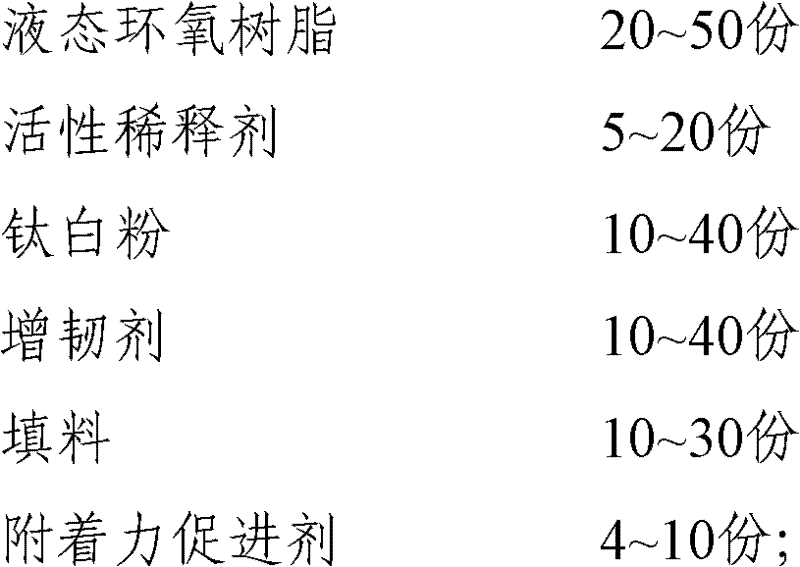

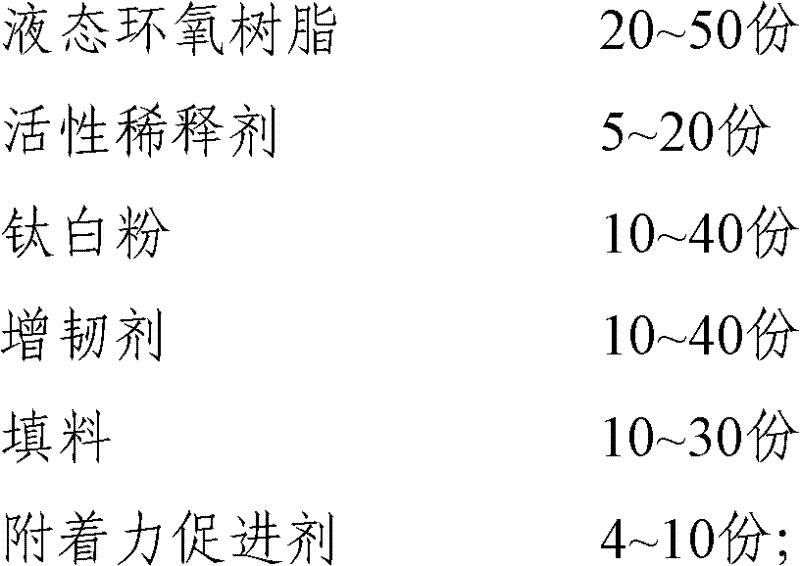

Method used

Image

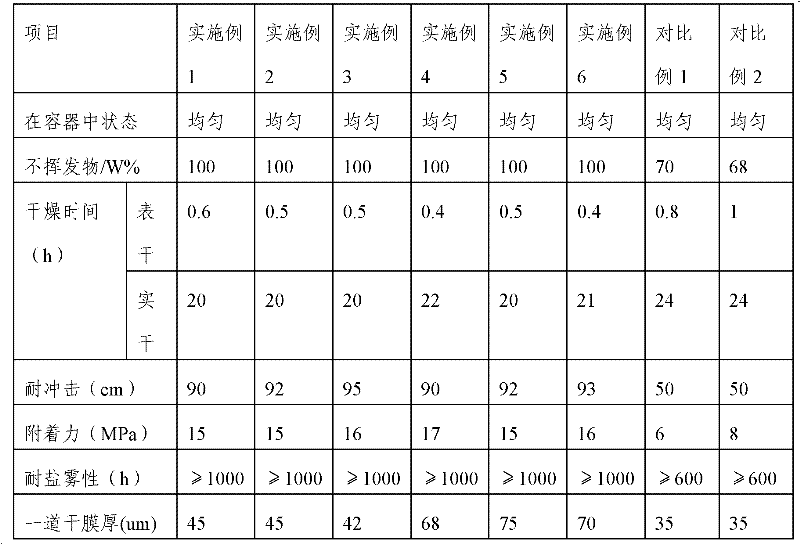

Examples

Embodiment 1

[0034] Preparation of component A: 20Kg of liquid epoxy resin (Jiangsu Sanmu Group Co., Ltd. SM618), 0.5Kg of vinyl bishard amide, 20Kg of glycidyl neodecanoate (ShigenaTM10 of Hebei Siyou Excellence Technology Co., Ltd.), polyamide Wax 0.5Kg, titanium dioxide (Henan Baililian Chemical Co., Ltd. R-699) 10Kg, mineral fiber (Shenzhen Jinlonghui Industrial Co., Ltd., wollastonite powder, JLH-SWx2) 10Kg, talcum powder 10Kg dispersed to a fineness of Below 50 microns, heat to 60°C, keep warm for 30 minutes, and finally put in 2,4,6-tris(dimethylaminomethyl)phenol 4Kg, 2-(4-thiazolyl)benzimidazole 0.5Kg, BYK-066N0. 2Kg is uniformly dispersed to obtain component A;

[0035] Preparation of component B: Add cardanol formal diethylenetriamine 60Kg, benzophenone imine (Nanjing Aike Pharmaceutical Technology Co., Ltd.) 20Kg, 2,4,6-tris(dimethylamino Methyl) phenol 0.5Kg, glycidyl neodecanoate 5Kg, stir well, get B component;

[0036] Take 9Kg A component and 2Kg B component and mix even...

Embodiment 2

[0038] Preparation of component A: liquid epoxy resin (Jiangsu Sanmu Group Co., Ltd. SM618) 50Kg, monoglyceride stearate 1.5Kg, trimethylolpropane triglycidyl ether 5Kg, polyamide wax 1.5Kg, titanium dioxide ( Henan Baililian Chemical Co., Ltd. R-699) 40Kg, glass fiber powder (Hangzhou High-Tech Composite Material Co., Ltd.) 40Kg, kaolin 30Kg dispersed until the fineness is below 50 microns, heated to 70°C, kept for 30 minutes, and finally put in 2 , 10Kg of 4,6-tris(dimethylaminomethyl)phenol, 1.5Kg of methyl benzimidazole carbamate, and 0.5Kg of polydimethylsiloxane were uniformly dispersed to obtain component A;

[0039] Preparation of component B: Add cardanol formal diethylenetriamine 20Kg, benzophenone imine (Nanjing Aike Pharmaceutical Technology Co., Ltd.) 60Kg, 2,4,6-tris(dimethylamino Methyl) phenol 1.5Kg, glycidyl neodecanoate 20Kg, stir well, get B component;

[0040] Take 11Kg A component and 2Kg B component and mix evenly for testing, the results are shown in Ta...

Embodiment 3

[0042] Preparation of component A: liquid epoxy resin (Jiangsu Sanmu Group Co., Ltd. SM828) 35Kg, vinyl bishard amide 1Kg, trimethylolpropane triglycidyl ether 15Kg, polyamide wax 1Kg, titanium dioxide (Henan Bai Lilian Chemical Co., Ltd. R-699) 30Kg, carbon fiber powder (Qinhuangdao City Zichuan Carbon Fiber Co., Ltd.) 35Kg, barium sulfate 20Kg dispersed until the fineness is below 50 microns, heated to 60 ° C, kept for 60 minutes, and finally put in 2,4 , 5Kg of 6-tris(dimethylaminomethyl)phenol, 1Kg of methyl benzimidazole carbamate, and 0.35Kg of BYK-066N were uniformly dispersed to obtain component A;

[0043] Preparation of component B: Add cardanol formal diethylenetriamine 40Kg, benzophenone imine (Nanjing Aike Pharmaceutical Technology Co., Ltd.) 35Kg, 2,4,6-tris(dimethylamino Methyl) phenol 1Kg, cresyl glycidyl ether 15Kg, stir well, get B component;

[0044] Take 10Kg A component and 2Kg B component and mix evenly for testing, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com