Amine composition and application thereof, polyurethane resin and preparation method and application thereof

A technology of polyurethane resin and composition, applied in the field of polyurethane, which can solve the problems of intense polymerization reaction process, difficult production control, difficult control of reaction speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] (iii) Preparation method of ink:

[0086] Sand mill 30 parts by weight of polyurethane resin solution prepared by the present invention, 30 parts by weight of titanium dioxide, 20 parts by weight of ethyl acetate and 20 parts by weight of isopropanol with a sand mill until the ink fineness is 20 μm, Ink is prepared.

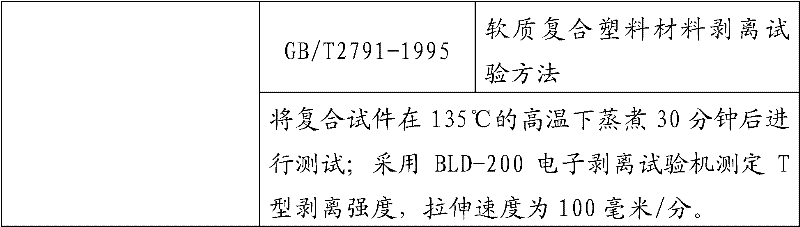

[0087] (iv) Preparation method of composite test piece:

[0088] Print ink with a thickness of 40 μm on the substrate, and apply a two-component polyurethane adhesive (purchased from Beijing Gaomeng New Materials Co., Ltd.) with a thickness of 40 μm on the top of the ink layer, and then place the substrate on Place in an oven at 80°C for 1 minute. Finally, the substrate and the composite substrate were bonded together, and then aged in an oven at 45°C for 48 hours to make a composite specimen, cooled to room temperature, and the composite specimen was cut into test strips with a width of 15 mm and a length of 100 mm. In the following examples, the combi...

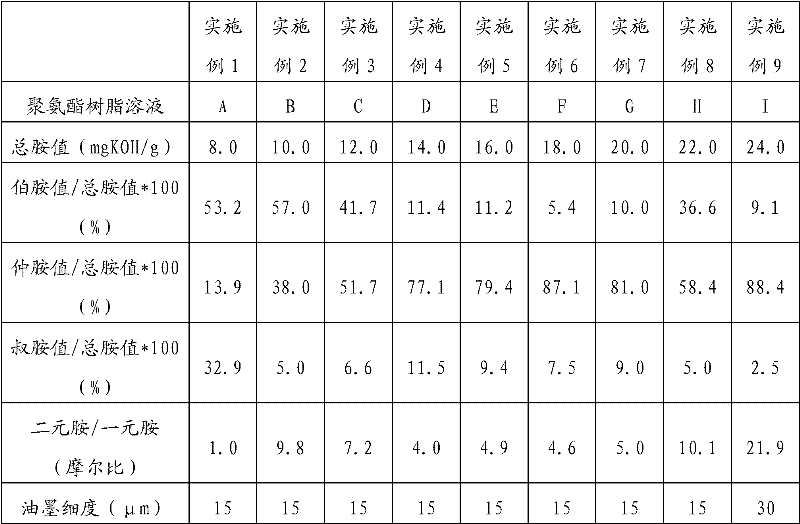

Embodiment 1

[0090] 95 parts by weight of polyester diols and 3.5 parts by weight of hexamethylene diisocyanate and 0.05 parts by weight of dibutyltin dilaurate are packed into a four-necked flask equipped with a stirrer and a thermometer. ℃ for 6 hours to make a prepolymer. A mixed solution consisting of 0.02 parts by weight of 1,4-butanediol, 0.05 parts by weight of vegetable oil polyol with a hydroxyl value of 163 mgKOH / g and 50 parts by weight of ethyl acetate was added, and the mixture was incubated at 75° C. for 4 hours. Next, add a mixed solution consisting of 0.71 parts by weight (0.016mol) of methylenediamine, 0.72 parts by weight (0.016mol) of dimethylamine, 150 parts by weight of ethyl acetate and 33.3 parts by weight of isopropanol. It was made to react at 30°C for 30 minutes. The temperature was raised to 70° C. and the reaction was maintained for 3 hours. The resin solid content of the polyurethane resin solution A obtained in this way is 30.2% by weight, the number average...

Embodiment 2

[0092] 93 parts by weight of polyether diols and 4 parts by weight of toluene diisocyanate and 0.05 parts by weight of stannous octoate are loaded into a four-necked flask equipped with a stirrer and a thermometer, and are incubated at 30° C. for 8 hours under a nitrogen stream. made into prepolymers. A mixed solution consisting of 1 part by weight of trimethylolpropane, 0.5 part by weight of vegetable oil polyol with a hydroxyl value of 163 mgKOH / g and 50 parts by weight of ethyl acetate was added, and the mixture was incubated at 75° C. for 4 hours. Next, add a mixed solution consisting of 1.7 parts by weight (0.0283mol) of ethylenediamine, 0.7 parts by weight (0.0029mol) of di-n-octylamine, 150 parts by weight of ethyl acetate and 33 parts by weight of isopropanol. It was allowed to react at -30°C for 30 minutes. The temperature was raised to 70° C. and the reaction was maintained for 3 hours. The resin solid content of the polyurethane resin solution B obtained in this w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com