Ceramic ball lapping method based on combined-type fixation abrasive material grinding disc

A grinding method and composite technology, applied in grinding devices, grinding machine tools, grinding tools, etc., can solve the problems of difficulty in processing V-shaped grooves on the surface of abrasive tools, low utilization rate of fixed abrasive tools, and difficulty in making grinding discs, etc., and achieve reduction The effect of processing auxiliary time, reducing difficulty, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

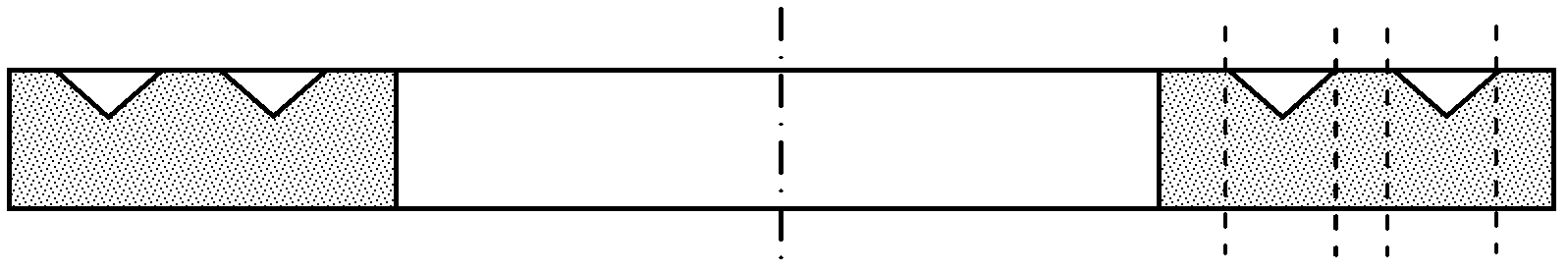

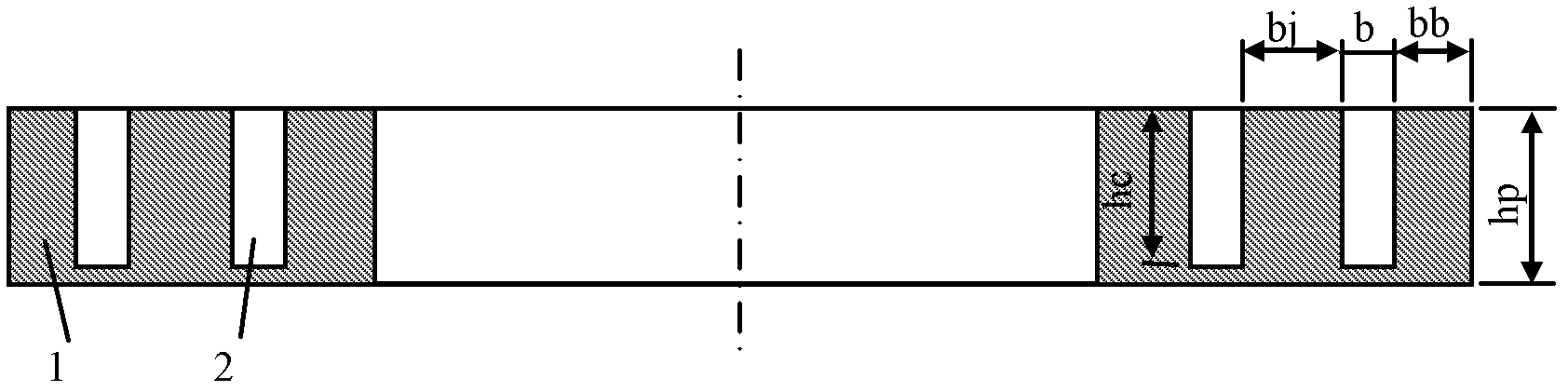

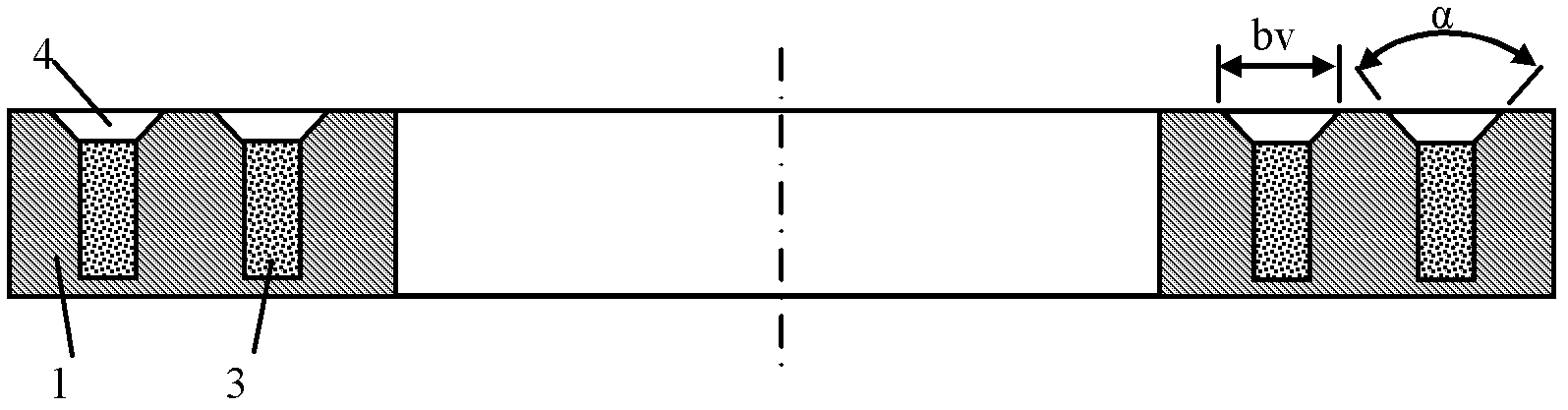

[0033] refer to Figure 1 to Figure 5 , a ceramic ball grinding method based on a composite fixed abrasive disc, the grinding method comprises the following steps:

[0034] 1) The processing process of the composite fixed abrasive disc:

[0035] 1.1) Processing of the cast iron grinding disc (basic structure) annular groove structure: the composite fixed abrasive tool is based on the cast iron grinding disc 1, and the cast iron grinding disc is a cast iron grinding disc commonly used for ceramic ball grinding. Its hardness is 150-250. According to the diameter d of the ceramic ball 5 to be processed, an annular groove 2 is processed on the grinding disc, and the groove width b is 2 / 3~4 / 5 of the diameter of the ceramic ball to be processed, that is, b=2 / 3·d~4 / 5 d (mm). The groove depth hc is determined according to the thickness hp of cast iron grinding, and the gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com