Bush fixing press-mounting machine for automobile gearbox

A technology of automobile gearboxes and press-fitting machines, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as no way to guarantee yield and low efficiency, and achieve simple and practical structure, accurate and fast installation, and automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

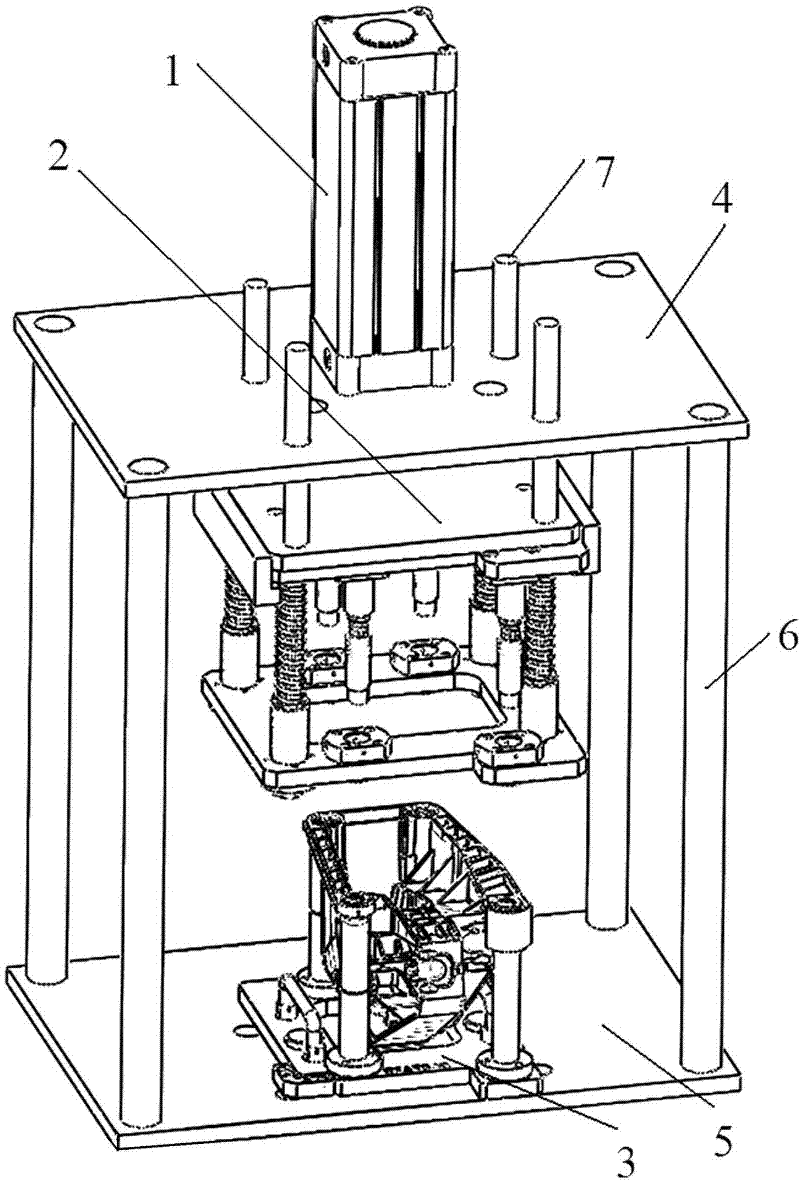

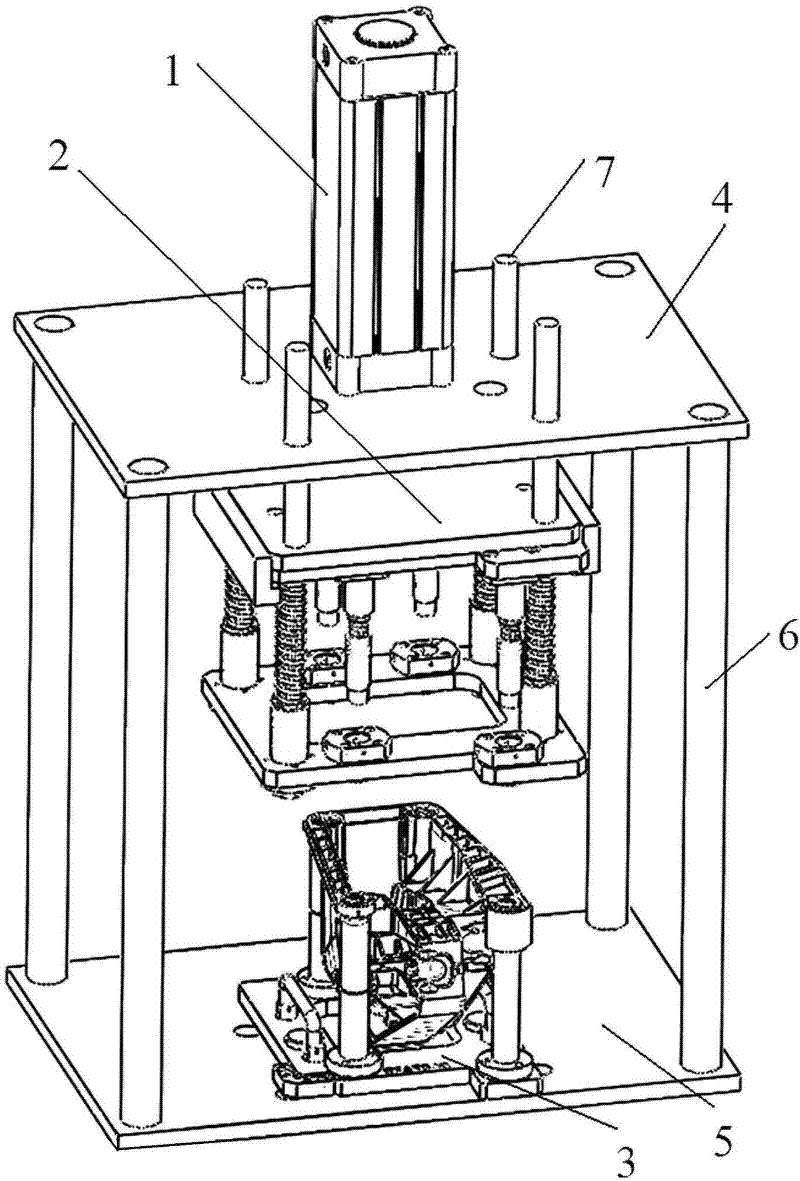

[0014] figure 1 It is a structural schematic diagram of a preferred embodiment of the automobile gearbox fixed bush pressing machine of the present invention.

[0015] refer to figure 1 As shown, the automobile gearbox fixed bushing pressing machine of the present invention comprises: a cylinder 1, a frame, a multi-stage pressing part 2, and a fixing fixture 3; the frame includes: an upper top plate 4, a base plate 5, supported on the upper top plate 4 and the support column 6 around the base plate 5; the cylinder barrel of the cylinder 1 is fixed above the upper top plate 4, and its piston rod protrudes downward through the upper top plate 4; the multi-stage press-fitting part 2 is arranged on the upper top plate 4 It is fixedly connected with the base plate 5 and the free end of the piston rod of the cylinder 1, the fixing jig 3 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com