Hydrogen-induced crack resisting high-ductility ultra-low hydrogen welding electrode

A hydrogen-induced crack resistance, high toughness technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as equipment damage and explosion, and achieve stable arc, easy slag removal, and excellent welding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Adopt the general manufacturing process in the welding rod production industry, make the welding core according to the welding core formula in Table 1-1, prepare the welding rod coating according to the coating formula in Table 1-2 and prepare the welding rod coating by dry mixing and wet mixing, and apply the welding rod coating onto the core to form it:

[0050] Table 1-1 Solder core formula (unit: weight percentage)

[0051] C

Si

mn

Cr

Ni

P

S

Fe

0.06

0.03

0.45

0.04

0.04

0.006

0.003

margin

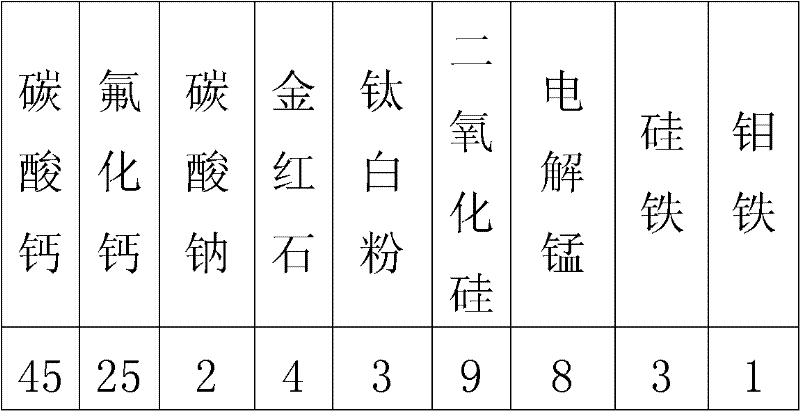

[0052] Table 1-2 drug skin formula (unit: weight percentage)

[0053]

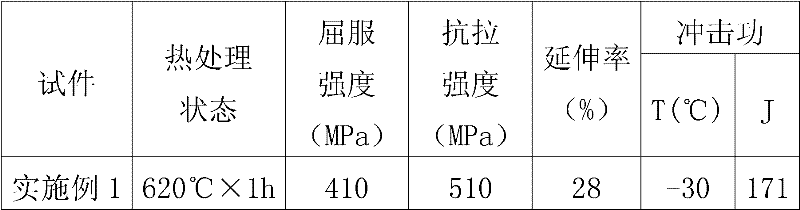

[0054] The chemical composition of the deposited metal is shown in Table 1-3, the mechanical properties are shown in Table 1-4, the results of the diffusible hydrogen test are shown in Table 1-5, and the results of the corrosion test (HIC) are shown in Table 1-6:

[0055] Table 1-3 Chemical composition of ...

Embodiment 2

[0067] Adopt the general manufacturing process in the welding rod production industry, make the welding core according to the welding core formula in Table 2-1, prepare the welding rod coating according to the coating formula in Table 2-2 and prepare the welding rod coating by dry mixing and wet mixing, and apply the welding rod coating onto the core to form it:

[0068] Table 2-1 Solder core formula (unit: weight percentage)

[0069] C

Si

mn

Cr

Ni

P

S

Fe

0.03

0.03

0.35

0.04

0.03

0.005

0.004

margin

[0070] Table 2-2 Drug skin formula (unit: weight percentage)

[0071]

[0072] The chemical composition of the deposited metal is shown in Table 2-3, the mechanical properties are shown in Table 2-4, the content of diffusible hydrogen is shown in Table 2-5, and the HIC corrosion test results are shown in Table 2-6:

[0073] Table 2-3 Chemical composition of deposited metal (we...

Embodiment 3

[0082] Adopt the general manufacturing process in the welding rod production industry, make the welding core according to the welding core formula in Table 3-1, prepare the welding rod coating according to the coating formula in Table 3-2 and prepare the welding rod coating by dry mixing and wet mixing, and apply the welding rod coating onto the core to form it:

[0083] Table 3-1 Solder core formula (unit: weight percentage)

[0084] C

Si

mn

Cr

Ni

P

S

Fe

0.01

0.05

0.30

0.012

0.20

0.005

0.001

margin

[0085] Table 3-2 Drug skin formula (unit: weight percentage)

[0086]

[0087] The chemical composition of the deposited metal is shown in Table 3-3, the mechanical properties are shown in Table 3-4, the content of diffusible hydrogen is shown in Table 3-5, and the HIC corrosion test results are shown in Table 3-6:

[0088] Table: 3-3 Chemical composition of deposited metal (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com