Steel plate with excellent hydrogen-induced cracking resistance and toughness, and line pipe steel tube

A hydrogen-induced crack resistance and toughness technology, which is applied in the field of steel pipes for line pipes, can solve the problems that it is difficult to ensure high toughness of the surface layer at the same time, and achieve the effect of excellent hydrogen-induced crack resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

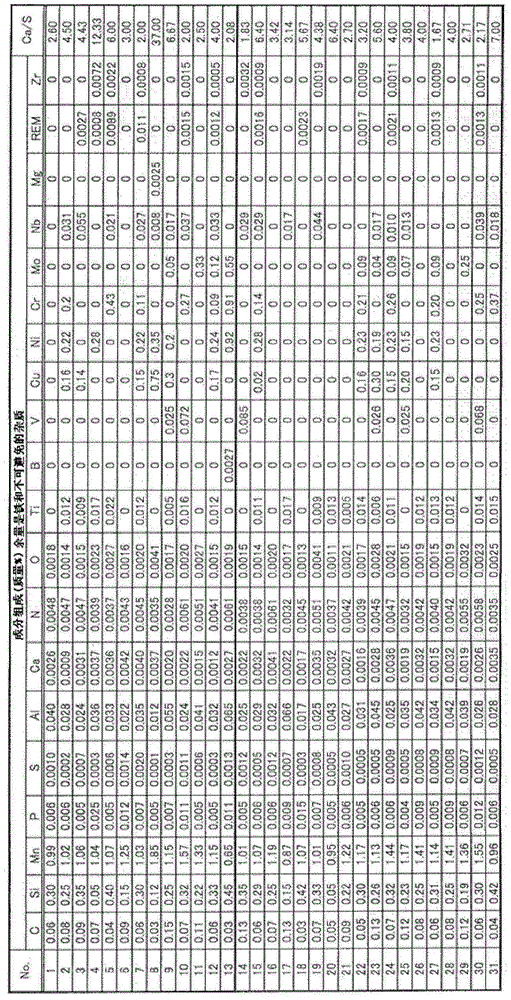

Examples

Embodiment Construction

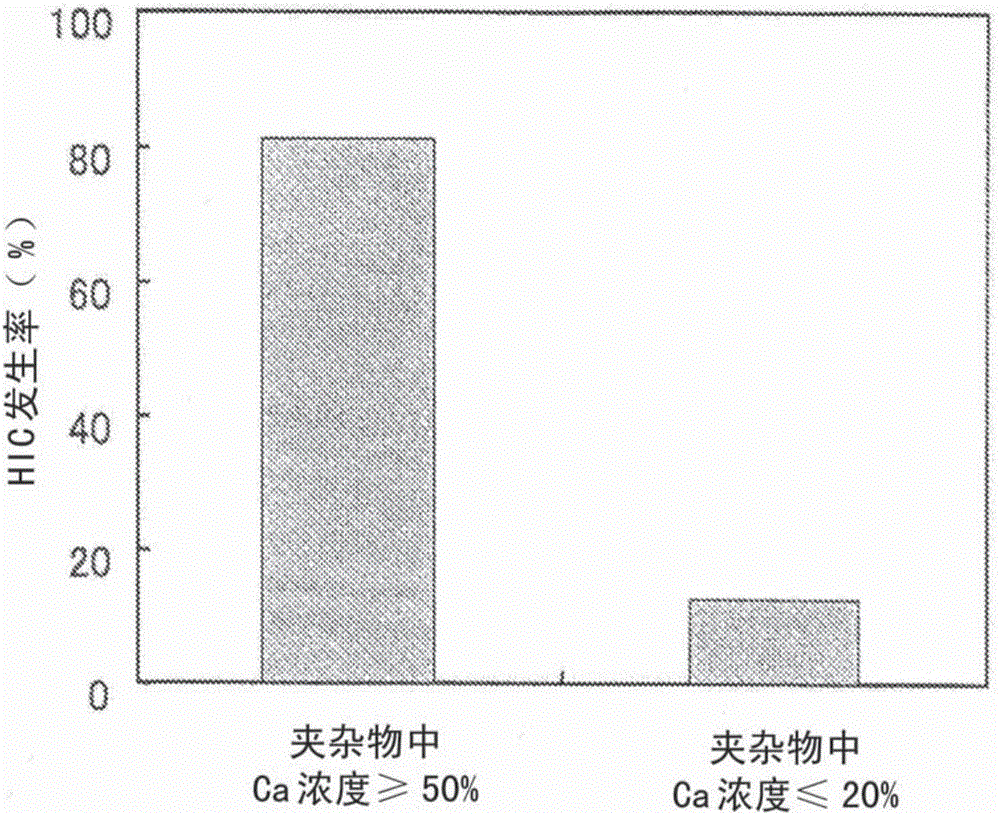

[0033] The inventors of the present invention have made intensive studies in order to solve the above-mentioned problems. First, the inventors of the present invention conducted the HIC test (NACE test) specified in NACE (National Association of Corrosion and Engineer) TM0284 using each steel plate in order to re-examine the cause of HIC occurrence in the surface layer of the steel plate under the most severe condition in a sulfur-containing environment. . In this NACE test, a test piece, that is, a steel plate, is immersed in a mixed aqueous solution of pH 2.7 of 5% NaCl solution saturated with 1 atm of hydrogen sulfide gas and 0.5% acetic acid for 96 hours, and then the occurrence of HIC is evaluated.

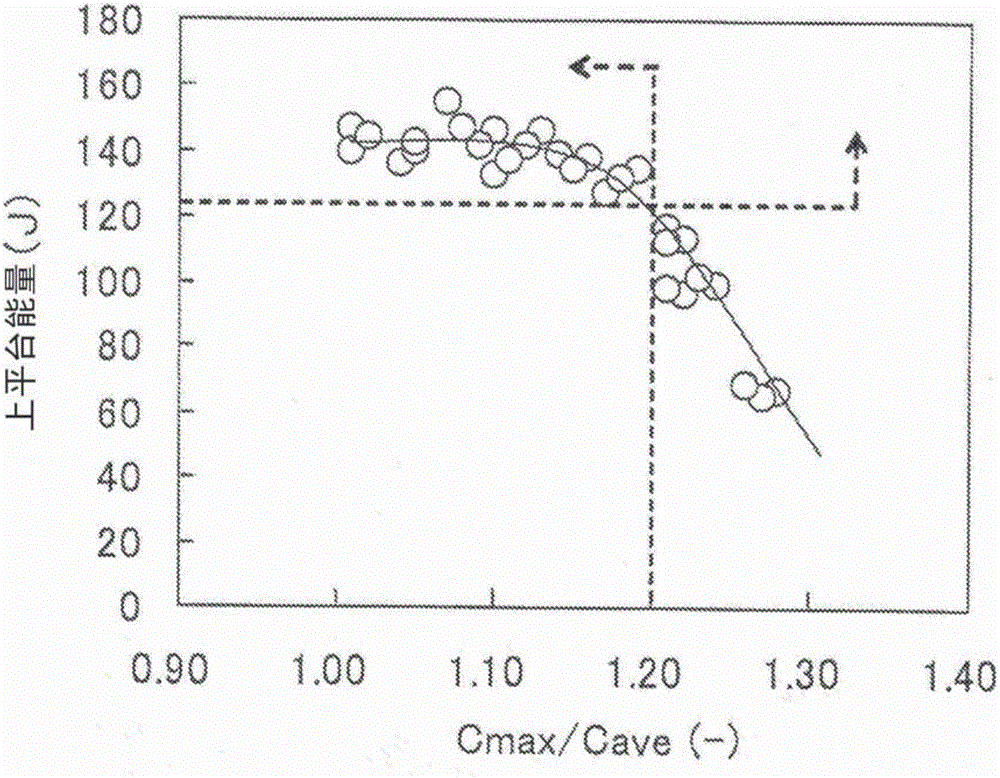

[0034] Next, the present inventors implemented a pendulum impact test in compliance with ASTMA370 on the surface portion of the steel plate after the HIC test. As a result, even when no cracks are observed in the NACE test under the prescribed "microscopic observation with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com