Steel pipe and steel sheet

A technology for steel plates and steel pipes, applied in furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of reduced SSC resistance, accelerated cooling, and surface hardening of steel plates, and achieve excellent DWTT characteristics, sulfide stress crack resistance and hydrogen induced resistance. Excellent effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0201] Next, examples of the present invention will be described. The conditions in the examples are examples of conditions employed to confirm the practicability and effects of the present invention, and the present invention is not limited to such examples of conditions. The present invention can adopt various conditions as long as the object of the present invention is achieved without departing from the gist of the present invention.

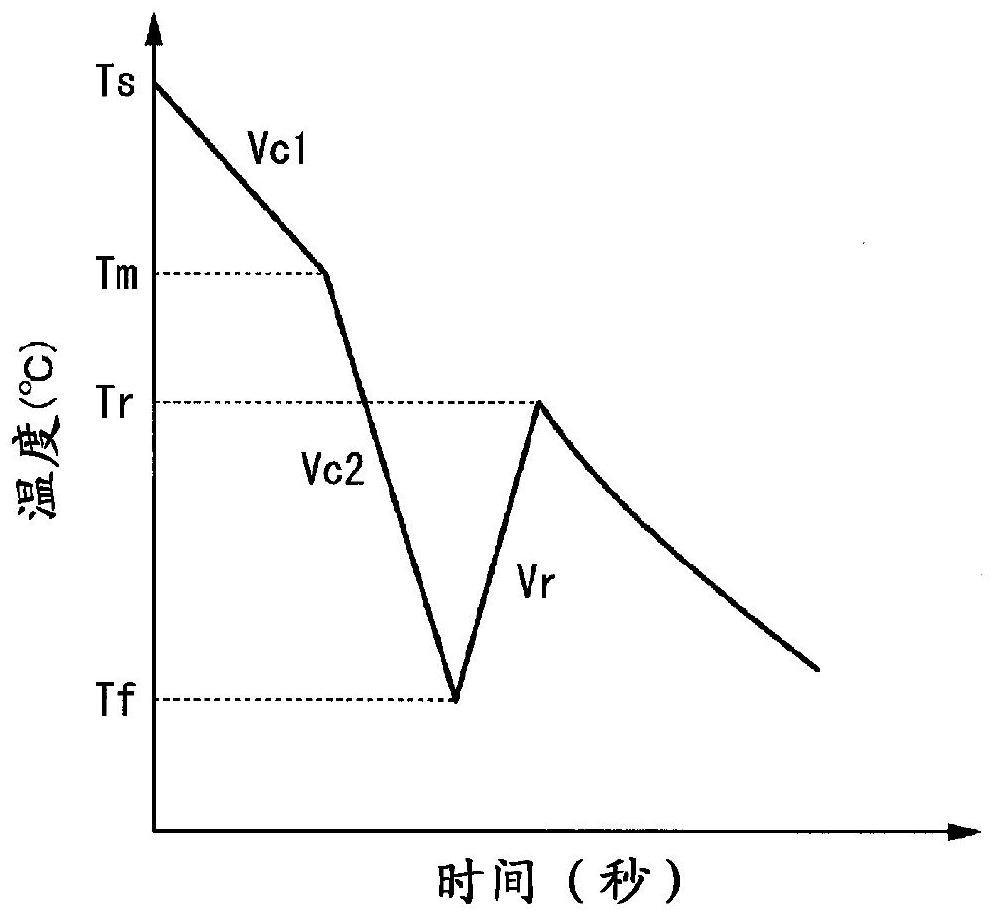

[0202] Steel sheets having the chemical composition (the balance being Fe and impurities) and Ceq shown in Table 1 were hot-rolled, cooled, and reheated under the conditions shown in Table 2A and Table 2B to manufacture steel sheets.

[0203]

[0204]

[0205]

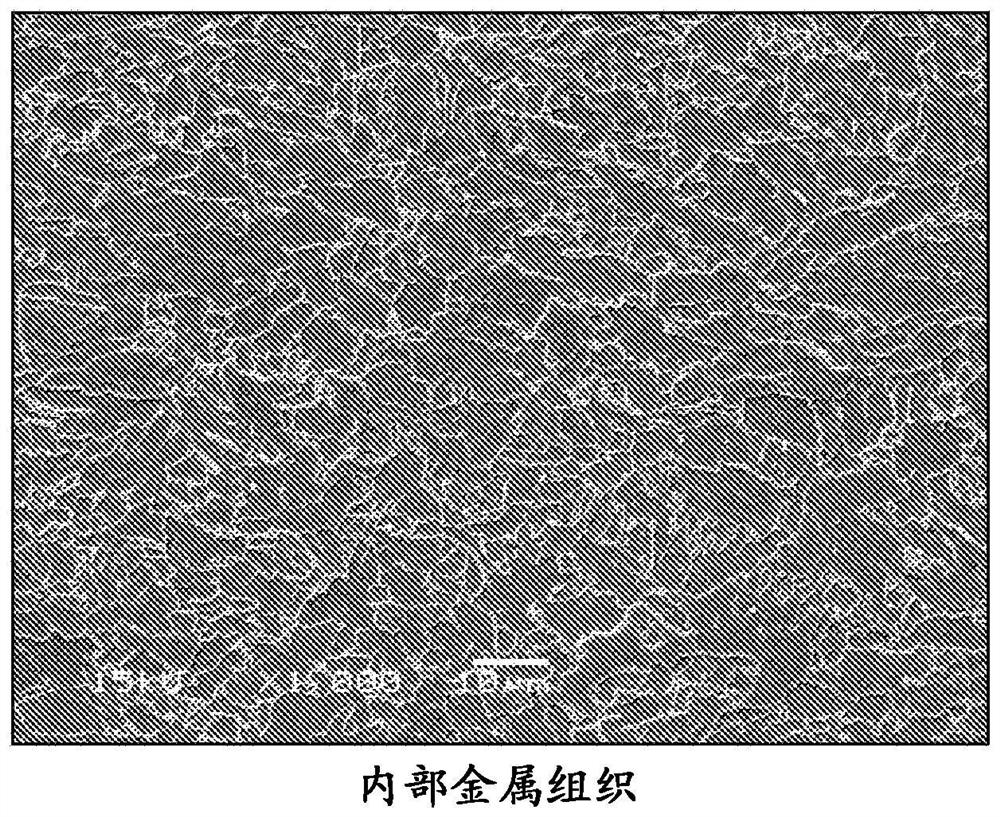

[0206] A test piece was prepared from the manufactured steel plate, and the structure at a position (t / 4) of 1 / 4 of the plate thickness from the surface of the steel plate was observed with a scanning electron microscope at a magnification of 1000 times to determine the inte...

Embodiment 2

[0223] The steel plates shown in Tables 1 to 3 are formed into tubular shapes by C-type forming machine, U-type forming machine, and O-type forming machine, and the end faces are tack welded, formally welded from the inner and outer surfaces, and then expanded to produce Steel pipes for pipelines. Furthermore, submerged arc welding was used for formal welding.

[0224] In the table, the steel plate No.S-x (x=1 to 54) was formed to be steel pipe No.P-x (x=1 to 54).

[0225]A test piece was prepared from the base material portion of the produced steel pipe, and the fraction (area ratio) of each structure of the surface layer metal structure and the internal metal structure was calculated. Specifically, the microstructure at the 1 / 4 position (t / 4) of the plate thickness from the steel plate surface was observed with a scanning electron microscope at a magnification of 1000 times, and the internal metal structure was determined. The rest of the structure not described in the tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com