Soft stabproof bulletproof material and preparation method thereof

A bulletproof and soft technology, applied in protective equipment, chemical instruments and methods, offensive equipment, etc., can solve the problem of difficult industrialization of stab-resistant layer processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

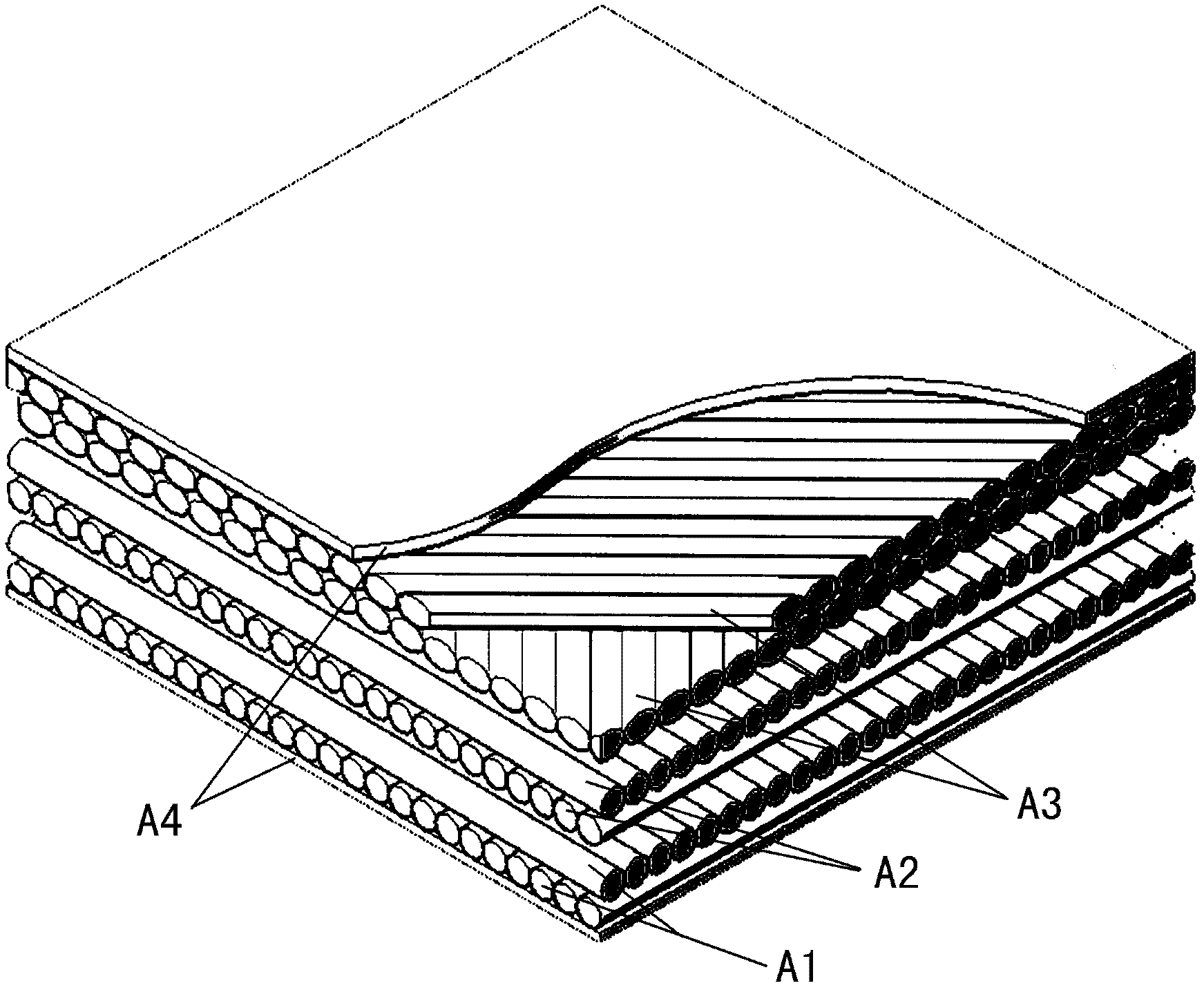

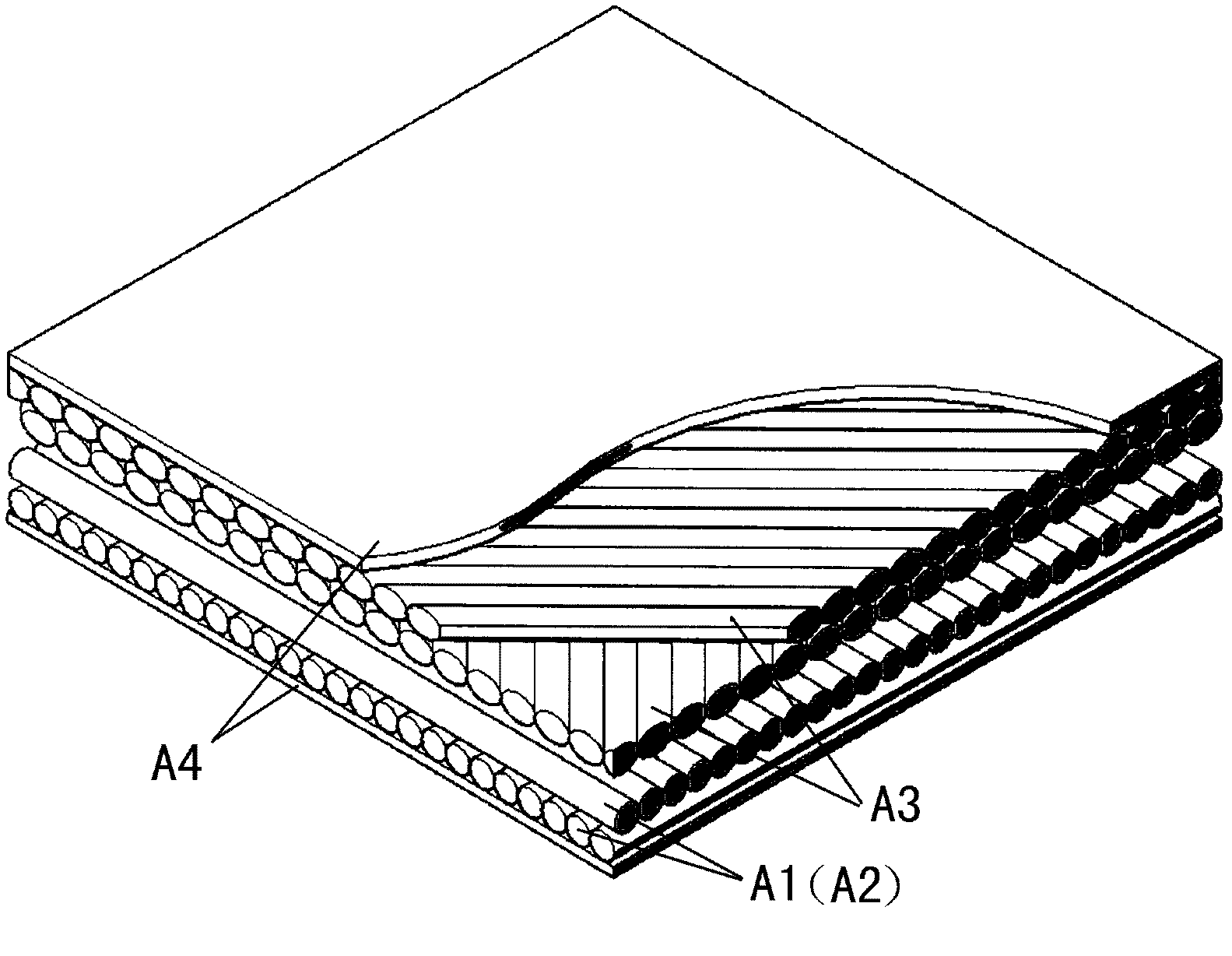

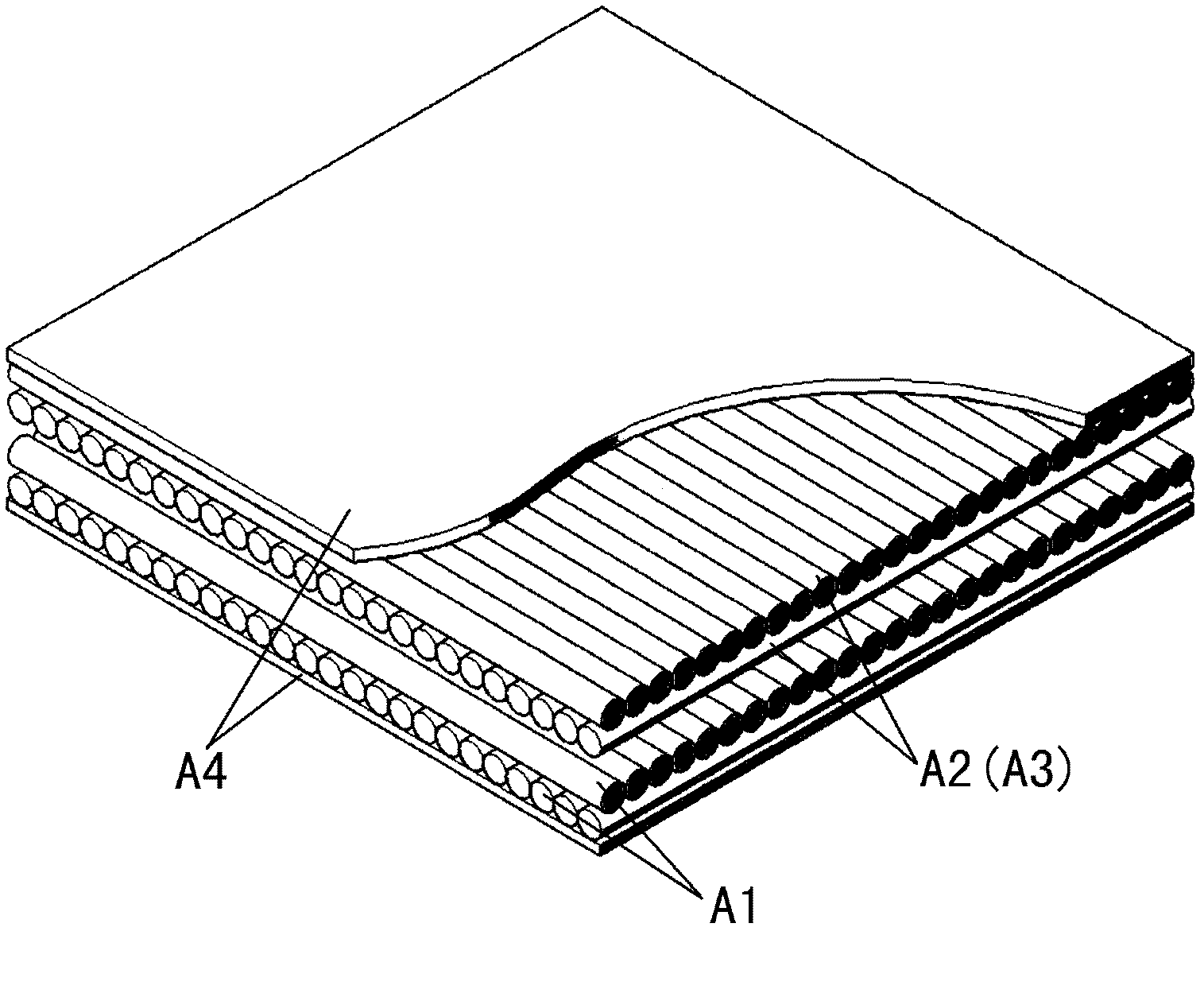

[0050] 1) Preparation of continuous rolls of single-oriented prepreg tape without liner

[0051] The high-strength and high-modulus fibers are placed on the parallel wire frame, and the fiber tows are evenly spaced under the drag of the tractor. The high-strength and high-modulus fibers are synchronously fed into the friction roller device, and the high-voltage static electricity is carried by the static friction fibers. Under the action of electrostatic force, they repel each other and achieve a uniform arrangement state; the fibers are dipped and scraped, and the adhesive is cured and formed, so that the single orientation of the high-strength and high-modulus fibers is maintained in a uniform state, and the single orientation of the unlined film fiber is obtained under further drying. Continuous rolls of prepreg tape;

[0052] 2) Preparation of continuous rolls of two-layer orthogonal composite single-oriented fiber prepreg tape without liner film

[0053] Cut the continuo...

Embodiment 1

[0081] Production of continuous rolls of mono-oriented prepreg tape without liner

[0082] Place ZTX99 about 600d (240f) high-strength high-modulus polyethylene (HSHM-PE) fibers (breaking strength ≥ 35cN / dtex, modulus ≥ 1100cN / dtex, elongation at break ≈ 3%) on parallel wire racks. The fiber tow is dragged by a seven-roller tractor, passes through a reed of 5 reeds / cm, and is evenly spaced within a width of 1.20M, and the fibers are synchronously fed into the friction roller device. Under the drag of the rear tractor, the fibers carry high-voltage static electricity through static friction, and the monofilaments in the bundle of fibers repel each other under the action of electrostatic force to achieve uniform arrangement, and then dipped in glue through the dipping roller (adhesive is styrene-ethylene-butylene) -Styrene polymer (SEBS), styrene-ethylene-ethylene-propylene-styrene polymer (SEEPS) or a mixture of the two as the main solvent-based adhesive, the adhesive content i...

Embodiment 2

[0084] Preparation of Continuous Coil of Two-layer Orthogonal Composite Mono-Oriented Prepreg Tape Without Liner Film

[0085] The continuous roll of the single-oriented prepreg tape without liner film in the embodiment was cut into a 1.20M square sheet for subsequent orthogonal compounding.

[0086] Repeat the operation of Example 1. After the single-oriented fiber is dipped, the adhesive is not yet dry. The 1.20M square sheet is superimposed and bonded in the form of adjacent two-layer fiber orientation orthogonal, and then pressurized in the rolling compound machine. Composite, achieve [0 / 90] orthogonal online composite, become [0 / 90] two-layer orthogonal composite single-oriented prepreg tape continuous coil without liner film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com