Method for manufacturing ultrahigh-tension wire with single-crystal alloy material

An alloy material and tension wire technology, which is applied in the improvement of process efficiency, photography technology, instruments, etc., can solve problems such as inability to adapt to requirements, and achieve the effect of improving oxidation resistance, high heat resistance, and high electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

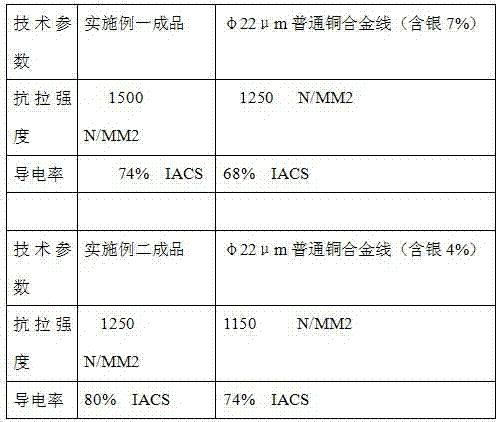

Examples

Embodiment 1

[0015] ① Extraction of high-purity copper: Dilute the copper nitrate solution with high-purity water at a ratio of 1:4 to prepare an electrolyte; use the national standard No. 1 pure copper as the anode to immerse in the electrolyte, and ensure that 95% of the volume ratio of pure copper is immersed in the electrolysis liquid; use high-purity copper foil as the cathode to immerse in the electrolyte, and also ensure that high-purity copper foil with a volume ratio of 955 is immersed in the electrolyte; input 7-9V, 2.5-3.5A direct current between the anode and cathode to Supplement fresh electrolyte to keep the temperature of the electrolyte not exceeding 60°C; when the cathode accumulates high-purity copper with a purity greater than 99.9995%, replace the high-purity copper foil in time, and then clean and dry it for later use.

[0016] ② Prepare copper alloy ingots: extract high-purity copper with a purity greater than 99.9999%, then add silver, aluminum, palladium, beryllium, ...

Embodiment 2

[0023] Step 1. is the same as embodiment one.

[0024] ② Prepare copper alloy ingots: extract high-purity copper with a purity greater than 99.9999%, then add silver, aluminum, palladium, beryllium, and rare earth, and feed Cu 92-97 parts, Ag 1-4 parts, Al 0.2 parts according to the following parts by weight -1.4 parts, 0.3-3 parts of palladium, 0.2-4 parts of beryllium, 2-7 parts of rare earth. The purity of silver is greater than 99.99%, the purity of aluminum is greater than 99.999%, the purity of palladium is greater than 99.999%, and the purity of beryllium is greater than 99.999%. These metals are mechanically mixed and placed in a high-purity graphite crucible, and the induction furnace is used under the protection of inert gas. Melting, in order to ensure the stability and consistency of the chemical composition, it is prepared into an alloy ingot;

[0025] remaining steps To step 7. with embodiment one.

[0026] The technology of the present invention abandons th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com