Copper mould casting and ironing combined method for preparing corrosion-resistant Zr-based amorphous alloy

A zirconium-based amorphous and corrosion-resistant technology, which is applied in the field of preparation of corrosion-resistant zirconium-based amorphous alloys, can solve the problems of limited surface roughness and corrosion resistance of zirconium-based amorphous alloy components, and achieve good component surface treatment Effect, improvement of anti-corrosion performance, effect of excellent surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

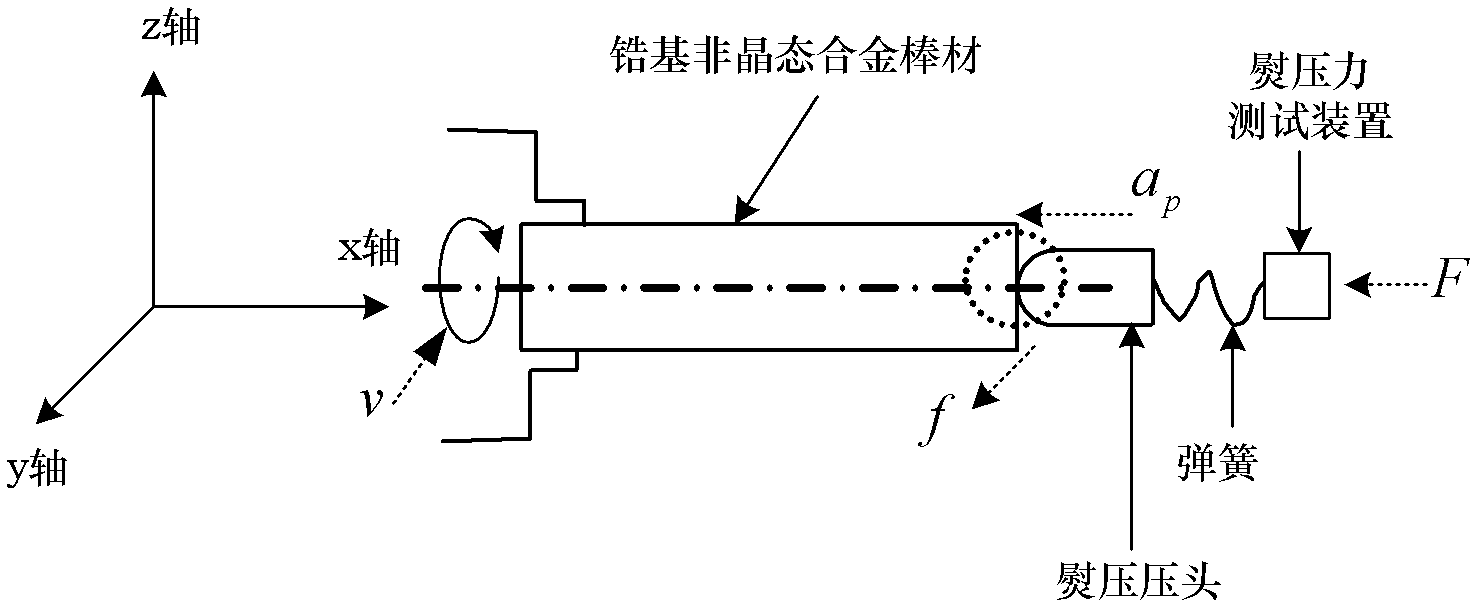

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 prepares Zr 47 Al 10 Cu 40 Y 3 Amorphous Alloy Rods

[0058] Step 1: Press Zr 47 Al 10 Cu 40 Y 3 The chemical composition of the amorphous alloy is proportioned for batching;

[0059] Step 2: Smelting Zr 47 Al 10 Cu 40 Y 3 Master Alloy

[0060] Put the batching that step 1 makes into the vacuum smelting furnace;

[0061] Adjust the vacuum degree to 5×10 -3 Pa, then rush into 0.05MPa argon protective gas;

[0062] Adjust current 20A, melting temperature 1000℃;

[0063] After the melting time is 5-10 minutes, take out the master alloy after cooling with the furnace;

[0064] Step 3: Copper Mold Casting Rods

[0065] Put the master alloy obtained in step 2 into the induction furnace of the rapid solidification device;

[0066] Adjust the vacuum degree to 5×10 -3 Pa, then rush into 0.05MPa argon protective gas;

[0067] Adjust current 2A, induction temperature 850℃;

[0068] After smelting for 2 to 5 minutes, spray it into copper molds (cho...

Embodiment 2

[0079] Embodiment 2 prepares (Zr 55 Al 10 Ni 5 Cu 30 ) 99 Y 1 Amorphous Alloy Rods

[0080] Step 1: Press (Zr 55 Al 10 Ni 5 Cu 30 ) 99 Y 1 The chemical composition of the amorphous alloy is proportioned for batching;

[0081] Step 2: Melting master alloy

[0082] Put the batching that step 1 makes into the vacuum smelting furnace;

[0083] Adjust the vacuum degree to 5×10 -3 Pa, then rush into 0.05MPa argon protective gas;

[0084] Adjust current 20A, melting temperature 1000℃;

[0085] After the melting time is 5-10 minutes, take out the master alloy after cooling with the furnace;

[0086] Step 3: Copper Mold Casting Rods

[0087] Put the master alloy obtained in step 2 into the induction furnace of the rapid solidification device;

[0088] Adjust the vacuum degree to 5×10 -3 Pa, then rush into 0.05MPa argon protective gas;

[0089] Adjust current 2A, induction temperature 850℃;

[0090] After smelting for 2 to 5 minutes, it is sprayed into copper molds ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com