Nanometer rare earth inorganic substance/ rubber composite with high wear resistant and excellent dynamic property

A dynamic performance and nano-rare earth technology, which is applied in the field of nano-rare earth inorganic matter/rubber composite materials, can solve the problems of increased dynamic heat generation, poor fatigue resistance, poor compatibility between rare earth inorganic matter and rubber matrix, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

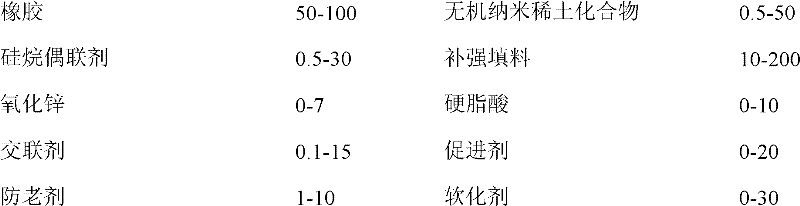

Method used

Image

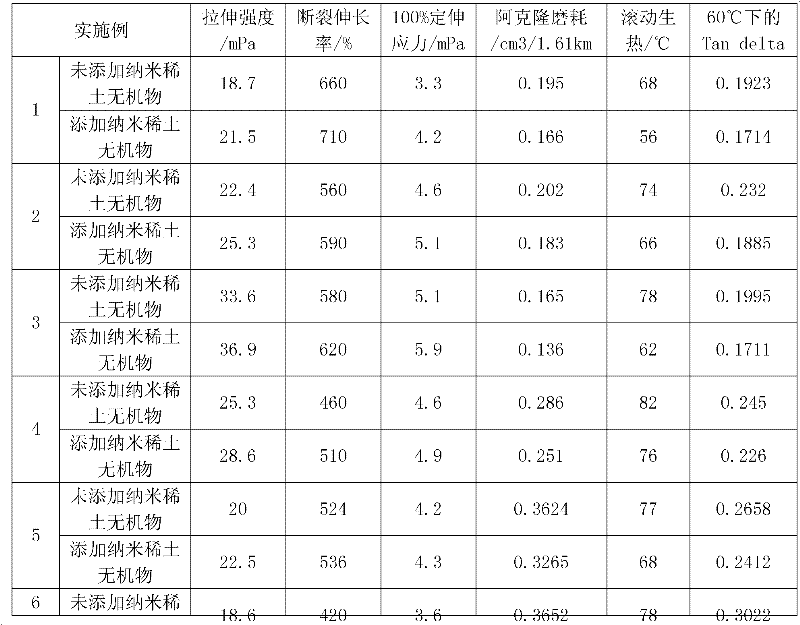

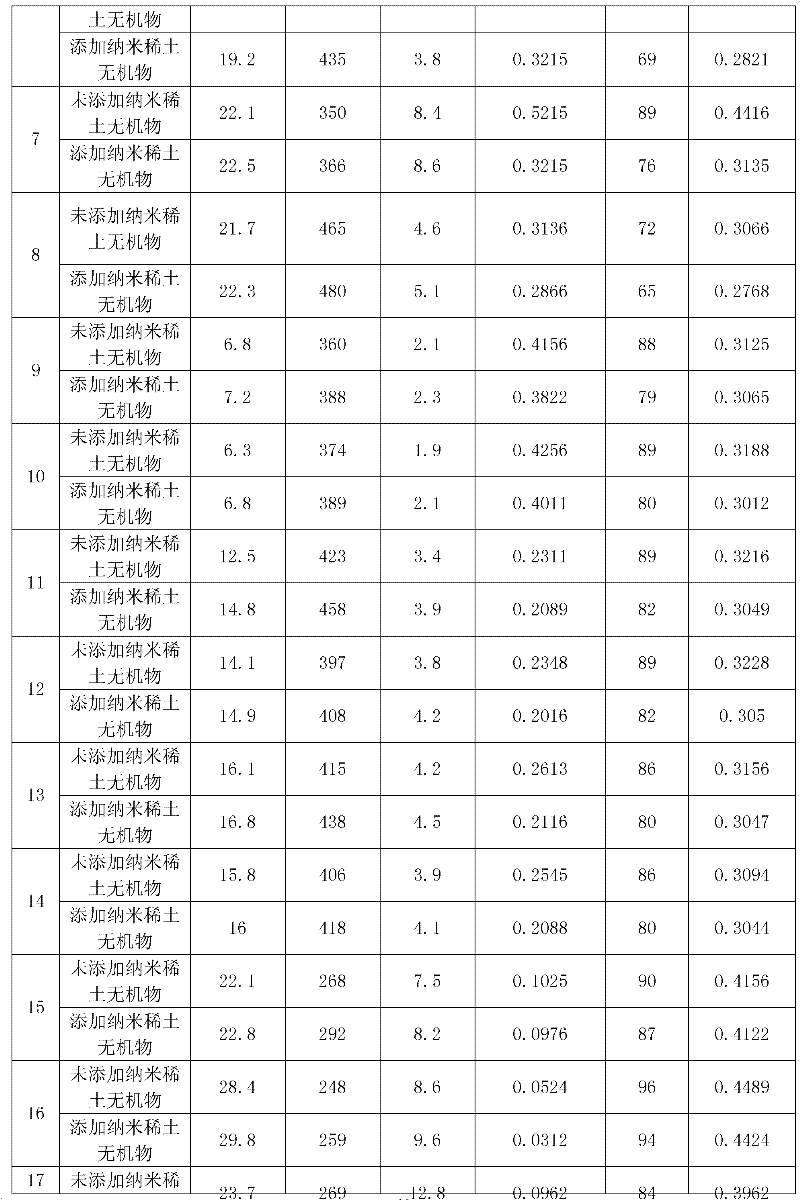

Examples

Embodiment 1

[0024] At room temperature, wrap 100 parts of natural rubber on double rollers on the rubber mixer, then add 5 parts of zinc oxide and 2 parts of stearic acid in sequence, and mix for 0.5 minutes; then add 0.5 parts of anti-aging agent RD, and add anti-aging agent 4010NA to 0.5 part, mixed for 2 minutes; then add 10 parts of VN3 white carbon black and 0.5 parts of Si69 in batches, then mix for 5 minutes, then add 0.5 parts of nano-lanthanum oxide, mix for 0.5 minutes, and finally add accelerator CZ1 in the open mill .5 parts and 3 parts of sulfur, thin pass 5 times to release the sheet, then park for 4 hours, then re-mill for 5 minutes and vulcanize to form a composite material.

[0025] Described accelerator CZ is N-cyclohexyl-2-benzothiazole sulfenamide; Si69 is two (triethoxysilylpropyl) tetrasulfides; Antiaging agent RD is 2,2,4-trimethyl- 1,2-dihydroquinoline polymer (belongs to ketone-amine reaction product antiaging agent); antiaging agent 4010NA is N-isopropyl-N`-pheny...

Embodiment 2

[0027] At room temperature, wrap 100 parts of natural rubber on double rollers on the rubber mixer, then add 5 parts of zinc oxide and 2 parts of stearic acid in sequence, and mix for 0.5 minutes; then add 4 parts of anti-aging agent RD, add anti-aging agent 4010NA to 5 1 part and 1 part of protective wax, mix for 5 minutes; then add 50 parts of VN3 silica and 10 parts of rector earth and 4 parts of Si69 in batches, then add 10 parts of carbon nanotubes, then mix for 10 minutes, then add 10 parts of nano-cerium oxide, mixed for 5 minutes, finally added 1.5 parts of accelerator CZ, 0.2 parts of accelerator TT and 3 parts of sulfur in the open mill, and thinly passed 5 times to produce tablets, then parked for 4 hours, and then returned Refined for 5 minutes and vulcanized to obtain a composite material.

[0028] The accelerator TT is tetramethylthiuram disulfide; the protective wax is a kind of anti-aging agent, which plays the role of anti-ozone aging and prolonging the servic...

Embodiment 3

[0030]At room temperature, wrap 100 parts of natural rubber on double rollers on the rubber mixer, then add 4 parts of zinc oxide and 1 part of stearic acid in sequence, and mix for 0.5 minutes; then add 4 parts of antioxidant MB, and add antioxidant 445 to make 5 5 parts and 4 parts of protective wax, mixed for 5 minutes; then add 50 parts of N234 carbon black and 4 parts of Si75 in batches, then mix for 10 minutes, then add 5 parts of nano-cerium oxide, 5 parts of nano-neodymium oxide, and nano-gadolinium carbonate 10 parts, 10 parts of nano-lanthanum hydroxide and 20 parts of nano-samarium nitrate, knead for 10 minutes, and finally add 1.5 parts of accelerator DM, 3 parts of accelerator DTDM and 2 parts of sulfur in the open mill, thin pass 5 times The sheet is released, then parked for 4 hours, then re-milled for 5 minutes and vulcanized to obtain a composite material.

[0031] The accelerator DM is 2,2'-dithiodibenzothiazole; the accelerator DTDM is 4,4'-dithiodimorpholin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com