Preparation method of microencapsulated gradient halogen-free flame retardant system

A technology of microencapsulation and inorganic flame retardants, which is applied in the field of composite materials, can solve the problems of poor compatibility between halogen-free flame Good combustion effect, low cost, and the effect of improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] ——Microencapsulation of halogen-free flame retardants:

[0030] a. After uniformly mixing 2.0 grams of ammonium polyphosphate and 1.0 grams of aluminum hydroxide, disperse them in 80 ml of chloroform, then transfer them to a four-necked flask with mechanical stirring and condenser, and heat at a stirring speed of 300 rpm At 55°C, add 30ml of chloroform solution containing 0.1g of toluene diisocyanate dropwise, and then gradually add 0.05g of melamine into the system after the dropwise addition, and continue the reaction for 7 hours, then stop heating and stirring.

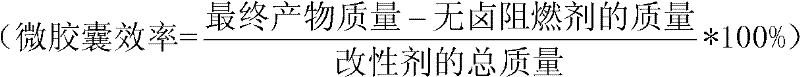

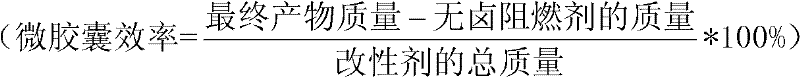

[0031] b. Vacuum suction filtration, wash twice with chloroform, then rinse twice with slightly hot distilled water, collect the filter cake, and dry it in a constant temperature vacuum drying oven at 50°C for 12 hours to finally obtain microencapsulated halogen-free barrier Fuel. Calculate the efficiency of microencapsulation.

[0032]

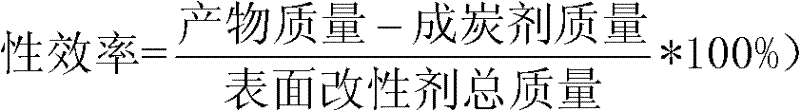

[0033] - Surface modification of pentaerythritol:

[0034] a. Pu...

Embodiment 2

[0040] ——Microencapsulation of halogen-free flame retardants:

[0041] a. After uniformly mixing 1.5 grams of ammonium phosphate and 1.5 grams of aluminum hydroxide, disperse them in 80 ml of chloroform, then transfer them to a four-necked flask with mechanical stirring and condenser, and the stirring speed is 300 rpm and heated to At 55°C, add 40ml of chloroform solution containing 0.1g of toluene diisocyanate dropwise. After the dropwise addition, gradually add 0.06g of melamine into the system and continue the reaction for 7 hours before stopping heating and stirring.

[0042] b. Vacuum suction filtration, wash twice with chloroform, then rinse twice with slightly hot distilled water, collect the filter cake, and dry it in a constant temperature vacuum drying oven at 50°C for 12 hours to finally obtain microencapsulated halogen-free barrier Fuel. Calculate the efficiency of microencapsulation.

[0043]

[0044] - Surface modification of pentaerythritol:

[0045] a. Put ...

Embodiment 3

[0051] ——Microencapsulation of halogen-free flame retardants:

[0052] a. After 1.5 grams of ammonium phosphate and 1.5 grams of magnesium hydroxide are evenly mixed, they are dispersed in 80ml of chloroform, and then transferred to a four-necked flask with mechanical stirring and condenser, and the stirring speed is 300 rpm and heated to At 55°C, add 20ml of chloroform solution containing 0.1g of diphenylmethane diisocyanate dropwise, and then gradually add 0.07g of melamine into the system after the dropwise addition, and continue the reaction for 7 hours, then stop heating and stirring.

[0053] b. Vacuum suction filtration, wash twice with chloroform, then rinse twice with slightly hot distilled water, collect the filter cake, and dry it in a constant temperature vacuum drying oven at 50°C for 12 hours to finally obtain microencapsulated halogen-free barrier Fuel. Calculate the efficiency of microencapsulation.

[0054]

[0055] - Surface modification of pentaerythrit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com